Solids Control Equipment

- Mud Shale Shaker

- Degasser

- Mud Cleaner

- Centrifuge

- Mud Agitator

- Mud Gun

- Jet Mud Mixer

- Centrifugal Pump

- Shear Pump

- Spray Pump

- Vacuum Pump

- Mud Gas Separator

- Ignition

- Drilling Cuttings Dryer

- Filter Press

- Conveyor

Mud Treatment System

- Drilling Fluid Solids Control System

- Water-based Mud Treatment System

- Oil based Mud Treatment System

- Trenchless Mud Treatment System

- Mud Mixing System

- Drilling Fluid Cooling System

- Truck mounted Mud Circulation System

- Barite Recovery System

Tank and Steel Structure

- Rig Mat

- Elevated Diesel Tank

- Nested Water Tank

- Fracturing Fluid Tank

- Drilling Pipe Basket

- Drill Cuttings Box

- Mud Storage Tank

Drilling Tools and Spare Parts

Phone: 86-29-88680837

Mail: sales@hlsolidscontrol.com

Add: Room 804, Building 1, Western Cloud Valley Phase II, Fengxi New Town, Xixian New District, Shaanxi Province

XBSY Centrifugal Pump

Product Overview:

Design features of HL SB series centrifugal pump:

1.Mechanical seals and packing seals are used, with high safety level.

2.Grease lubrication is used for shaft seals, and oil lubrication is used for bearings, with long service life.

3.Axial suction structure and wear-resistant components are used, which are wear-resistant and corrosion-resistant.

4.Good versatility and strong interchangeability of parts, and easy maintenance.

5.Metric and imperial standards are used, with wider applicability.

6.Complete categories, customizable to meet the different needs of various industries.

XBSY Centrifugal Pump Details

HL SB series centrifugal sand pump are 100% interchangeable with XBSY pumps. This pump is a newly designed and manufactured matching pump based on the characteristics of oil and gas drilling equipment. The pump adopts an axial suction structure, and the flow-through part is made of wear-resistant cast iron. It is suitable for conveying corrosive drilling fluid (containing suspended particles) or other liquid media in similar working conditions. It is the best matching pump for desander, desilter, and mixing hopper, and is also an ideal filling pump for mud pump.>>Send an Enquiry sales@hlsolidscontrol.com<<

The main seal of the HL SB series centrifugal sand pump is a wear-resistant carbide mechanical seal with a long service life; the auxiliary seal is a graphite packing seal to prevent accidents. Practice has proved that the SB series sand pump has reliable sealing and easy maintenance. The SB series sand pumps produced by our company have been used on land and offshore drilling platforms in more than 20 countries around the world. The results show that this series of pumps has very little maintenance costs except for the normal replacement of seals.>>Send an Enquiry sales@hlsolidscontrol.com<<

HL SB series centrifugal sand pump product types

SB series pumps include five models: SB6×8, SB5×6, SB4×5, SB3×4, and SB23.SB6×8 is equipped with 45kW, 55kW, and 75kW motors (six specifications of forward and reverse pumps can be provided according to customer needs).

SB5×6 is equipped with 22kW, 30kW, 37kW, and 45kW motors (four specifications of reverse pumps).

SB4×5 is equipped with 15kW and 22kW motors (two specifications of reverse pumps).

SB3×4 is equipped with 15kW, 11kW, and 7.5kW motors (three specifications of reverse pumps).

SB23 is equipped with motors (11kW, 7.5kW, and 5.5kW) (three specifications of reverse pumps).

SB6×8 sand pumps are recommended for drilling rigs above 3200m, and SB5×6 sand pumps are recommended for drilling rigs below 2500m.

| Model | Capacity (m3/h) | Head (m) | Speed(rpm) | Efficiency (%) | Power (kW) | Weight (kg) | Dimensions (mm) | ||

| / | / | / | 50 Hz | 60 Hz | / | Shaft power | Motor power | / | / |

| SB6 × 8J - 13 | 240 | 37 | 1480 | 1780 | 67 | 36 | 75 | 1130 | 2056×698×1022 |

| SB6 × 8J-12½ | 200 | 36 | 1480 | 1780 | 66 | 29.7 | 55 | 1000 | 1996×698×972 |

| SB6 × 8J - 12 | 200 | 33 | 1480 | 1780 | 64 | 28 | 45 | 850 | 1916×638×917 |

| SB5 × 6J-12½ | 200 | 33 | 1480 | 1780 | 64 | 28 | 45 | 785 | 1806×528 ×884 |

| SB5 × 6J - 12 | 180 | 31 | 1480 | 1780 | 63 | 24.1 | 37 | 760 | 1781×528×864 |

| SB5 × 6J-11½ | 160 | 28 | 1470 | 1780 | 62 | 19.7 | 30 | 650 | 1746×528×844 |

| SB5 × 6J - 11 | 140 | 22 | 1470 | 1780 | 62 | 13.5 | 22 | 545 | 1686×516×764 |

| SB4 × 5J - 10 | 150 | 25 | 1470 | 1780 | 61 | 16.8 | 22 | 480 | 1600×510×705 |

| SB4 × 5J - 9 | 93 | 20 | 1460 | 1760 | 58 | 8.8 | 15 | 400 | 1533×510×725 |

| SB3 × 4J - 10 | 85 | 26 | 1460 | 1760 | 61 | 9.9 | 15 | 360 | 1405×443×682 |

| SB3 × 4J-9½ | 80 | 23 | 1460 | 1760 | 61 | 8.2 | 11 | 340 | 1365×443×682 |

| SB3 × 4J - 9 | 54 | 18 | 1440 | 1750 | 60 | 4.4 | 7.5 | 290 | 1245×443×650 |

| SB2 × 3J - 10 | 55 | 22 | 1460 | 1760 | 60 | 5.5 | 11 | 320 | 1352×446×682 |

| SB2 × 3J - 9 | 50 | 18 | 1440 | 1750 | 56 | 4.4 | 7.5 | 260 | 1232×446×650 |

| SB2 × 3J - 8 | 40 | 16 | 1440 | 1750 | 54 | 3.2 | 5.5 | 245 | 1192×446×650 |

| SB2 × 3J-7½ | 25 | 11 | 1440 | 1750 | 50 | 1.5 | 4 | 223 | 1161×446×600 |

>>Send an Enquiry sales@hlsolidscontrol.com<<

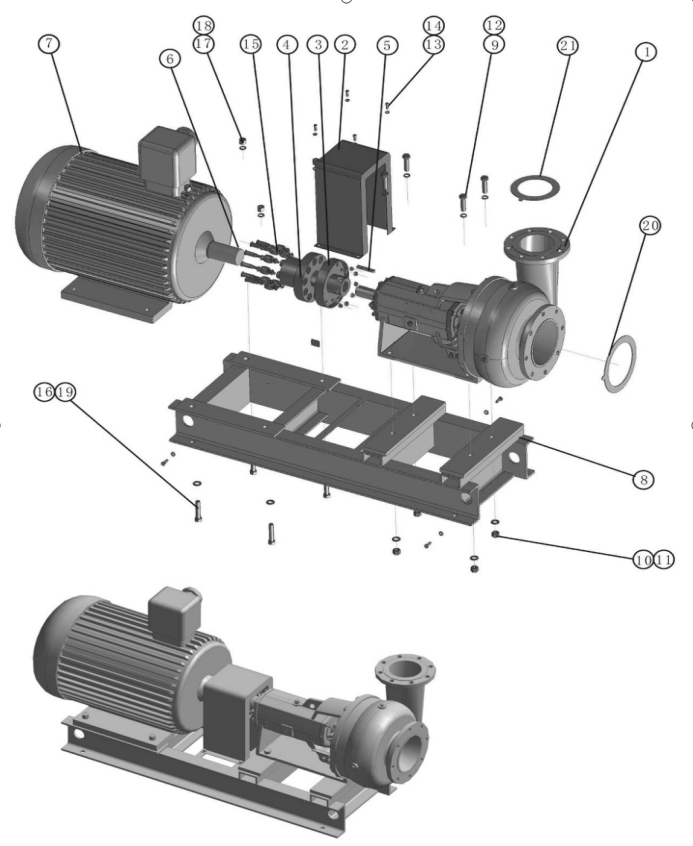

HL XBSY SB series centrifugal sand pump structure explosion diagram

HL XBSY SB Series Centrifugal Pump Parts List

| Item | Description | Part No. | Qty. | Item | Description | Part No. | Qty. |

| 1 | Pump head-FJ | SB68FJ0001S | 1 | 12 | Washer | SB68FJ0012S | 4 |

| 2 | Guard | SB68FJ0002S | 1 | 13 | Screw bolt | SB68FJ0013S | 4 |

| 3 | Pump jointer | SB68FJ0003S | 1 | 14 | Washer | SB68FJ0014S | 4 |

| 4 | Motor jointer | SB68FJ0004S | 1 | 15 | Pin and sheath loop | SB68FJ0015S | 10 |

| 5 | Key | SB68FJ0005S | 1 | 16 | Screw bolt | SB68FJ0016S | 4 |

| 6 | Key | SB68FJ0006S | 1 | 17 | Nut | SB68FJ0017S | 4 |

| 7 | Motor | SB68FJ0007S | 1 | 18 | Spring washer | SB68FJ0018S | 4 |

| 8 | Base | SB68FJ0008S | 1 | 19 | Washer | SB68FJ0019S | 4 |

| 9 | Screw bolt | SB68FJ0009S | 4 | 20 | Suction rubber pad | SB68FJ0020S | 1 |

| 10 | Nut | SB68FJ0010S | 4 | 21 | Discharge rubber pad | SB68FJ0021S | 1 |

| 11 | Spring washer | SB68FJ0011S | 4 |

>>Send an Enquiry sales@hlsolidscontrol.com<<

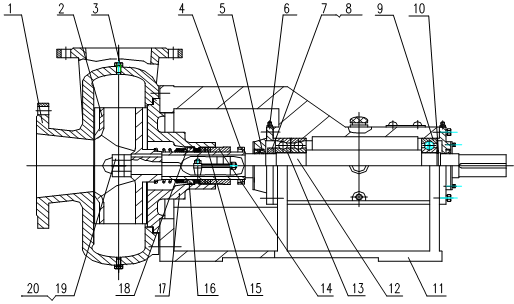

HL XBSY SB series centrifugal sand Sand pump structure diagram

| 1 | Pump case | 8 | Lock washer | 15 | Packing |

| 2 | Impeller | 9 | Bearing | 16 | Mechanical seal |

| 3 | Pipe plug | 10 | Collar | 17 | Stuffing Box, Mech Seal |

| 4 | Slinger | 11 | Pump base | 18 | Shaft sleeve |

| 5 | Oil seal | 12 | Shaft | 19 | Cap nut |

| 6 | Oil cup | 13 | Bearing | 20 | Square nut |

| 7 | Lock nut | 14 | Press plateassembly |

>>Send an Enquiry sales@hlsolidscontrol.com<<

FAQ

Q1: How can I make order online?

A: Send email or message(whatsApp/ wechat) us.you can ask any question ,after we confirm the detail, you can make order.

WhatsApp: 86-13735815206

E-mail: sales@hlsolidscontrol.com

Q2: Can I buy parts separately?

A: Yes, all of the pump spare parts can buy separately.