Solids Control Equipment

- Mud Shale Shaker

- Degasser

- Mud Cleaner

- Centrifuge

- Mud Agitator

- Mud Gun

- Jet Mud Mixer

- Centrifugal Pump

- Shear Pump

- Spray Pump

- Vacuum Pump

- Mud Gas Separator

- Ignition

- Drilling Cuttings Dryer

- Filter Press

- Conveyor

Mud Treatment System

- Drilling Fluid Solids Control System

- Water-based Mud Treatment System

- Oil based Mud Treatment System

- Trenchless Mud Treatment System

- Mud Mixing System

- Drilling Fluid Cooling System

- Truck mounted Mud Circulation System

- Barite Recovery System

Tank and Steel Structure

- Rig Mat

- Elevated Diesel Tank

- Nested Water Tank

- Fracturing Fluid Tank

- Drilling Pipe Basket

- Drill Cuttings Box

- Mud Storage Tank

Drilling Tools and Spare Parts

Phone: 86-29-88680837

Mail: sales@hlsolidscontrol.com

Add: Room 804, Building 1, Western Cloud Valley Phase II, Fengxi New Town, Xixian New District, Shaanxi Province

Poor Boy Degasser

Product Overview:

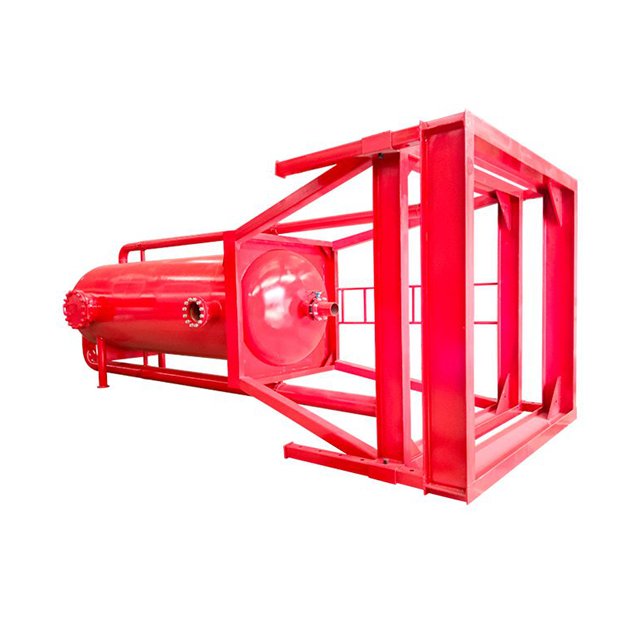

HL Petroleum is a professional manufacturer of Poor boy degasser. The mud gas separators produced mainly include 3 types according to their structure: fixed base type, lifting type, and folding type. Customized services is provided by HL Petroleum for mud gas separator, suitable structures and cylinder sizes can be designed according to your requirements.

Poor Boy Degasser Details

Poor boy degasser (mud gas separator) is one of the commonly used equipment in the drilling fluid solid control system. It is mainly used to separate large bubbles in the gas-invaded drilling fluids. Large bubbles here refer to the expanding gas with a diameter of about 3~25mm. If the bubbles remain in the drilling fluid, they may cause well kicks, endangering the safety of drilling workers. The difference between this degassing equipment and the degasser is mainly the size of the bubbles to be processed.

HL Petroleum is a professional manufacturer of Poor boy degasser. At present, the mud gas separators we produce mainly include 3 types according to their structure: fixed base type, lifting type, and folding type. Except HL Petroelum own brand, we also provide you with customized services, design suitable structures and Cylinder sizes according to your requirements. >>Send an Enquiry sales@hlshiyou.com<<

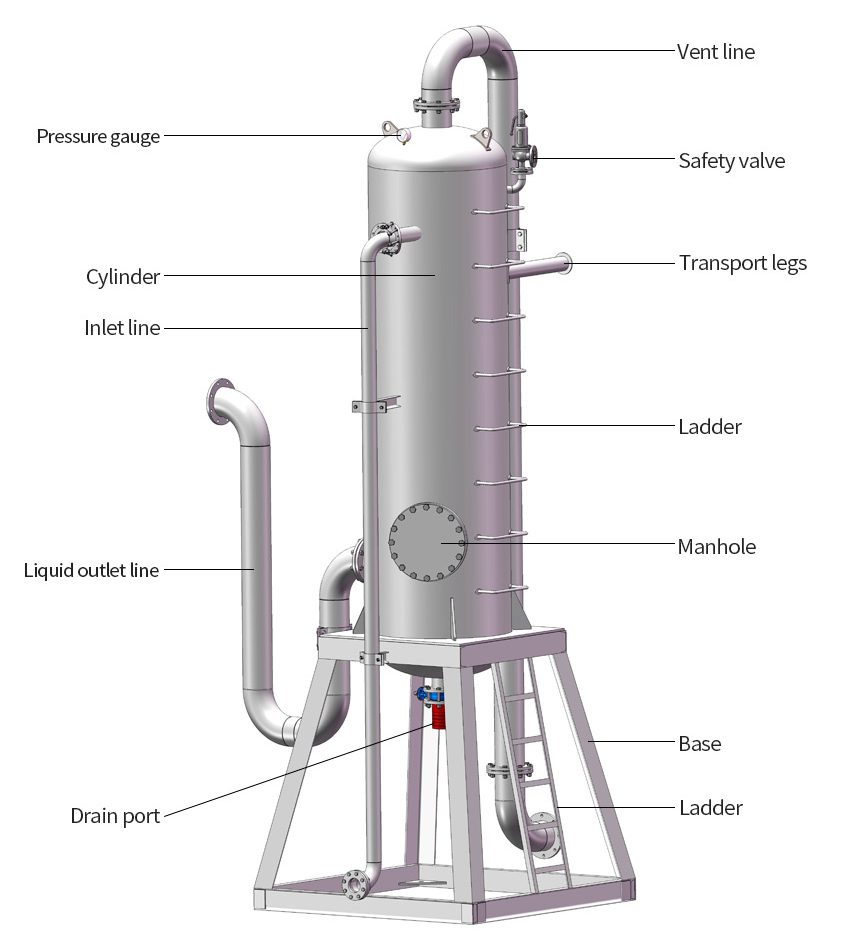

Working Principle

Drilling fluid with gas invades goes into the separator at the import tangentially and drops to a series baffles along the inner wall. After collision to increasing the contact area, It flows downward and become to a turbulent state which makes gas separate from mud and the free gas passes through the top of tank and discharged from the gas export. The length of gas export pipe can be determined at site and be induced to the safe place. The drilling fluid without gas will flow into the circular tank.

Technical Data

|

Model |

HYQ800 |

HYQ1000 |

HYQ1200 |

HYQ1400 |

|

Liquid handling capacity |

6,000m³/d |

7,000m³/d |

8,000m³/d |

8,000m³/d |

|

Gas handling capacity |

100,000m³/d |

120,000m³/d |

147,000m³/d |

147,000m³/d |

|

Cylinder Diameter |

800mm |

1,000mm |

1,200mm |

1,400mm |

|

Cylinder Volume |

≥1.6m³ |

≥3.0m³ |

≥4.0m³ |

≥6.0m³ |

|

Max. Working Pressure |

1.0MPa |

1.0MPa |

1.0MPa |

1.0MPa |

|

Gas Output Diameter |

159(6'')mm |

219(8'')mm |

219(8'')mm |

219(8'')mm |

|

Liquid Output Diameter |

219(8'')mm |

219(8'')mm |

273(10'')mm |

273(10'')mm |

|

Inlet Diameter |

133(5'')mm |

133(5'')mm |

133(5'')mm |

133(5'')mm |

|

Dimension |

1900X1900X5700mm |

2150X1960X4900mm |

2400X2000X6130mm |

2700X2600X7400mm |

|

Weight |

1,900KG |

2,300KG |

3,500KG |

3,800KG |

HL Petroleum support OEM services. If other specification of mud gas separator you are looking for, please >>Send an Enquiry sales@hlshiyou.com<<

The Features of HL Petroleum Poor Boy Degasser

1. It uses bottom drainage to control the working liquid level to ensure a constant liquid level in the separator and solve the problem of sand accumulation in the tank at the same time;

2. There is a special channel for gas separation in the liquid-gas separator tank, and the gas is emptied smoothly, which improves the gas treatment effect;

3. The liquid-gas separator adopts a combination of centrifugal separation, physical shock separation, vacuum separation and other separation technologies to ensure the gas separation effect;

4. Each bend of the liquid-gas separator supply pipe is equipped with a buffer device and a replaceable impact-resistant baffle is installed, which can be regularly inspected and replaced according to the wear and tear, which prolongs the service life of the equipment;

5. Liquid-gas separator anti-sulfur-type liquid-gas separator is manufactured and treated with special materials as a whole, which can completely prevent the damage of equipment by hydrogen sulfide gas in the gas.

Delivered Cases

Work with HL Petroleum

HL Petroleum is professional in drilling fluid solids control equipment production, which is a high-tech manufacturer in China.It is a one-stop provider of solids control equipment and solutions. The HL quality inspection team strictly inspects each component, and after the equipment is completed, debugs the entire solids control system until the equipment can work normally. The control has also passed the product quality certification of Xi'an Bureau of Quality and Technical Supervision. It can specifically design and match different drilling rigs and solid control equipment for horizontal directional drilling rigs according to the actual needs of customers and different working conditions. It can make the entire mud purification system become a a unified whole. And provide regular maintenance, system modification, system installation and other related services to minimize drilling costs and improve your economic benefits.