Solids Control Equipment

- Mud Shale Shaker

- Degasser

- Mud Cleaner

- Centrifuge

- Mud Agitator

- Mud Gun

- Jet Mud Mixer

- Centrifugal Pump

- Shear Pump

- Spray Pump

- Vacuum Pump

- Mud Gas Separator

- Ignition

- Drilling Cuttings Dryer

- Filter Press

- Conveyor

Drilling Tools and Spare Parts

- Mud Shale Shaker Spare Parts

- Centrifugal Pump Spare Parts

- Mud Pump Spare Parts

- Centrifuge Spare Parts

- Mud Tank Bottom Valve

- Mud Hopper

- Mud Tank Level Alarm

- Polyurethane Cyclone

- Electric Motor

- WPS Reducer

- Mud Tank Union

- Explosion-proof Water Tank Heater

Mud Treatment System

- Drilling Fluid Solids Control System

- Water-based Mud Treatment System

- Oil based Mud Treatment System

- Trenchless Mud Treatment System

- Mud Mixing System

- Drilling Fluid Cooling System

- Truck mounted Mud Circulation System

- Barite Recovery System

Tank and Steel Structure

Phone: 86-29-88680837

Mail: sales@hlsolidscontrol.com

Add: Room 804, Building 1, Western Cloud Valley Phase II, Fengxi New Town, Xixian New District, Shaanxi Province

Drilling Mud Desilter

Product Overview:

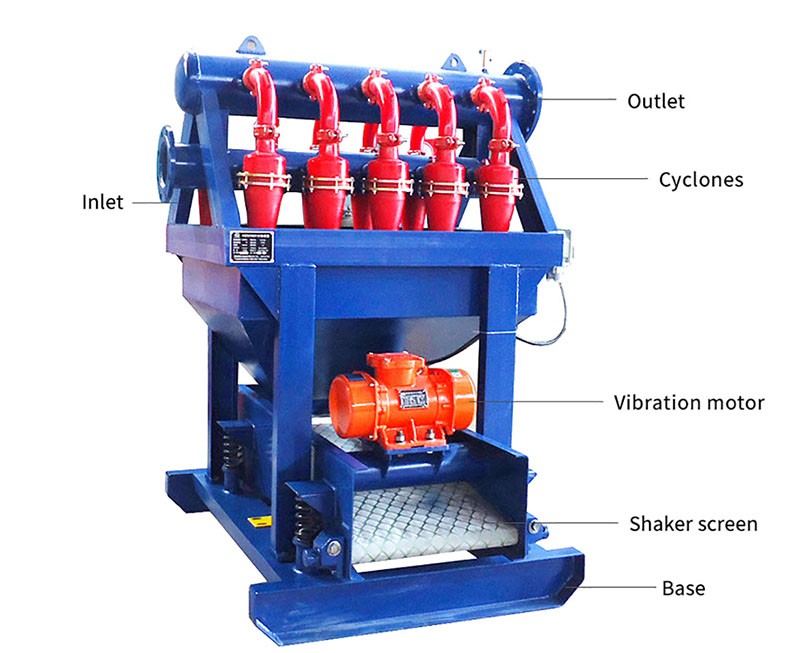

The drilling mud desilter is mainly composed of a vibrating screen, a manifold, a cyclone, etc. The desilter is a three-level solids control device used in the solid phase control system of the drilling fluid.

Drilling Mud Desilter Details

The mud desilter is a three-stage solids control device used in the solid phase control system of the drilling fluid. It is a combination of a cyclone desilter and a vibrating screen.

The desilter is designed according to the principle of particle sedimentation. The separation medium drilling fluid generates a certain pressure and speed through the sand pump, and spirals into the inner wall of the cyclone. The coarser particles flow along the cyclone under the action of centrifugal force and gravity. The inner wall of the vessel sinks spirally, discharged from the bottom flow port, and falls on the fine-mesh vibrating screen below to be separated, and the remaining medium spirally rises along the cyclone.

Desilter Features

1. The desilter has a high separation capacity and a wide separation particle size range;

2. The bottom outflow port of the cyclone is shaped like an umbrella-shaped "wet bottom" sand discharge so that the particles in the separation zone can be quickly discharged, reducing the probability of underflow port clogging;

3. Advanced small two The screen mud vibrating screen has large processing capacity, low noise and long screen life;

4. the symmetrical liquid inlet mechanism makes the swirling flow distribution reasonable and stable.

Drilling Mud Desilter Parameters

|

Model |

HCN100×4S |

HCN100×8S |

HCN100×10S |

HCN100×16S |

|

Capacity |

50 m3/h |

100 m3/h |

160 m3/h |

200 m3/h |

|

Cyclone Diameter |

100mm(4”) |

100mm(4”) |

100mm(4”) |

100mm(4”) |

|

Cyclone Quantity |

4 |

8 |

10 |

16 |

|

Separation Particle Size |

20~40μm |

20~40μm |

20~40μm |

20~40μm |

|

Motor Power |

0.5 KW |

0.5 KW |

0.5 KW |

0.75 KW |

|

Applicable Field |

Wells less than 100 meters |

Horizontal Directional Drilling |

4000m oil drilling |

Oil drilling above 5000 meters |

|

Supporting Sand Pump |

SB4×3-15KW |

SB5×4-22KW |

SB8×6-55KW |

SB8×6-55KW |

|

Weight |

550KG |

750KG |

800KG |

1100KG |

|

Dimension: L×W×H |

1500×800×1800 mm |

1500×1200×1800 mm |

1500×1300×1800 mm |

1500×1500×1800 mm |

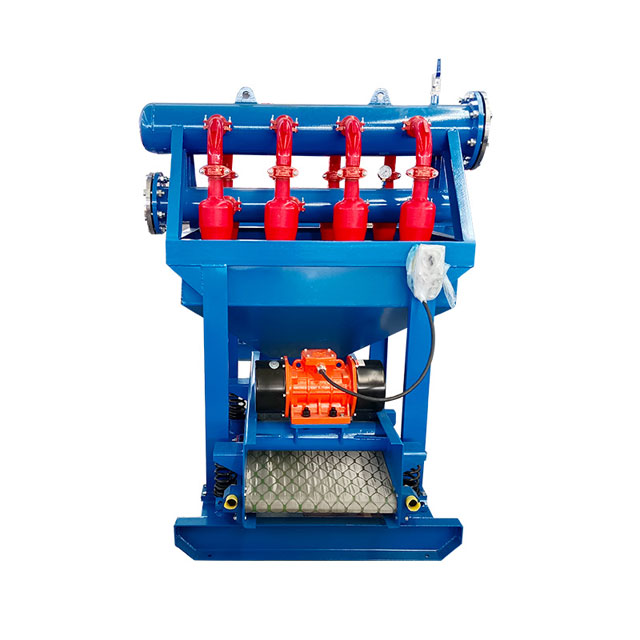

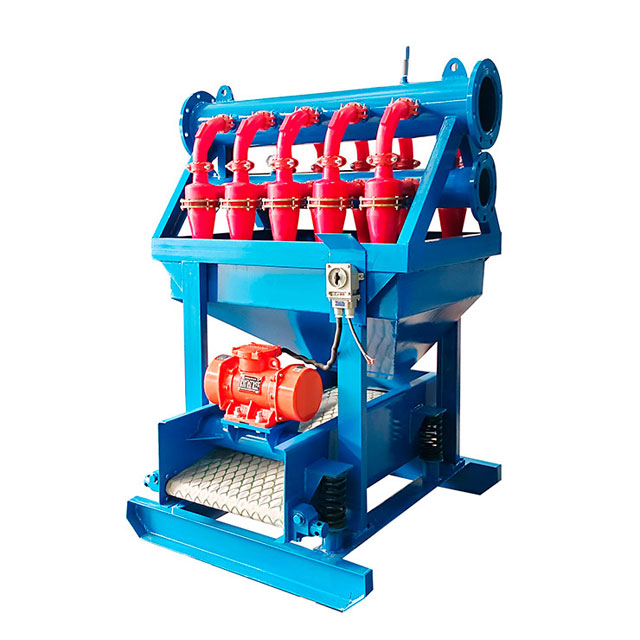

Drilling Mud Desilter Pictures

Hydrocyclone Desilter Using Site

Drilling Mud Desilter Installation and Debugging

1. The sludge cleaner should be installed behind the desander cleaner, that is, the end of the second tank, and the base must be placed stably.

2. The connecting pipelines between the inlet and outlet of the sludge cleaner and other equipment adopt hose lines, and minimize the length and bends as much as possible.

3. The tension of the screen should be appropriate, and the tensioned screen should be smooth and wrinkle-free.

Desilter Cleaner Maintenance

1. The screen box locking bolts must be removed before the first use of the newly purchased desilter cleaner or the first use after moving.

2. When the cyclone is out of service for a long time, it must be cleaned with clean water circulation to prevent dry sand from accumulating in the cyclone.

3. Grease the vibration motor every 1500~2500 hours, and the amount of oil for each bearing is 5~10ml.

4. The screen should be cleaned after the machine is shut down to prevent the sand from becoming dry and unusable next time.