Solids Control Equipment

- Mud Shale Shaker

- Degasser

- Mud Cleaner

- Centrifuge

- Mud Agitator

- Mud Gun

- Jet Mud Mixer

- Centrifugal Pump

- Shear Pump

- Spray Pump

- Vacuum Pump

- Mud Gas Separator

- Ignition

- Drilling Cuttings Dryer

- Filter Press

- Conveyor

Drilling Tools and Spare Parts

- Mud Shale Shaker Spare Parts

- Centrifugal Pump Spare Parts

- Mud Pump Spare Parts

- Centrifuge Spare Parts

- Mud Tank Bottom Valve

- Mud Hopper

- Mud Tank Level Alarm

- Polyurethane Cyclone

- Electric Motor

- WPS Reducer

- Mud Tank Union

- Explosion-proof Water Tank Heater

Mud Treatment System

- Drilling Fluid Solids Control System

- Water-based Mud Treatment System

- Oil based Mud Treatment System

- Trenchless Mud Treatment System

- Mud Mixing System

- Drilling Fluid Cooling System

- Truck mounted Mud Circulation System

- Barite Recovery System

Tank and Steel Structure

Phone: 86-29-88680837

Mail: sales@hlsolidscontrol.com

Add: Room 804, Building 1, Western Cloud Valley Phase II, Fengxi New Town, Xixian New District, Shaanxi Province

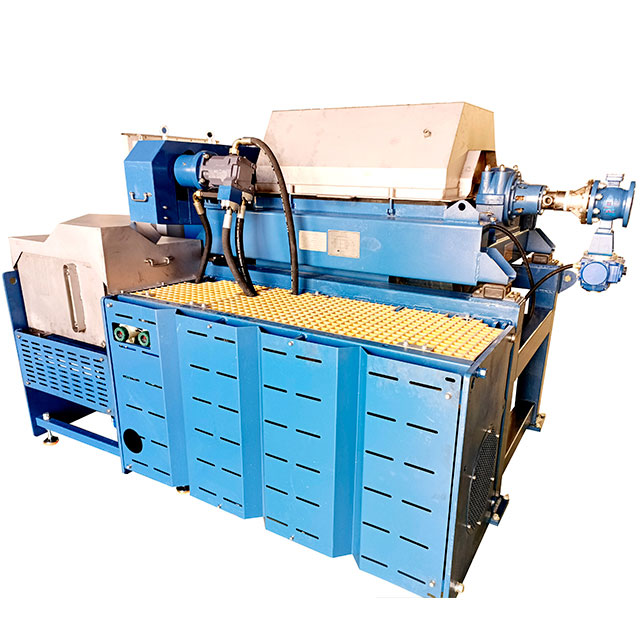

Centrifugal Mud Cleaner

Product Overview:

The centrifugal mud cleaner is similar to a large-diameter low-speed centrifuge, but because of its specially designed drum structure, it is suitable for processing mud at full displacement, removing drill cutting particles, and can remove sand when handling heavy mud but without reducing the mud specific gravity.

Centrifugal Mud Cleaner Details

Current desanders, desilters or mud cleaners use hydrocyclones as the core component of solid-liquid separation. Their disadvantages are high energy consumption (the cyclone needs to be driven by a 55 or 75 kw centrifugal pump) and unstable sand removal effect (clogging, wear, unstable pressure, etc. affect the separation effect), so the equipment efficiency is not high. The centrifugal mud cleaner is designed to solve the above problems

The centrifugal mud cleaner is similar to a large-diameter low-speed centrifuge, but because of its specially designed drum structure, it is suitable for processing mud at full displacement, removing drill cutting particles, and can remove sand when handling heavy mud but without reducing the mud specific gravity.

The results obtained from the operation process of many field applications show that the HMC-200 centrifugal mud cleaner did not have any failures. Compared with desanders, desilters, traditional mud cleaners and other equipment, the separation effect of the centrifugal desanding and desiltering machine is almost not affected by the addition of coating agents and other materials to the mud or the increase in mud viscosity. It is stable and reliable, has a large sand discharge capacity, can handle non-weighted mud at full discharge, and quickly solves mud problems such as clay and high sand content.

When processing weighted mud, the equipment can be operated at low speed, thereby effectively reducing the sand content of the mud without reducing the mud specific gravity. The power consumption of the equipment is smaller than when using a desander and a desilter at the same time. Therefore, one centrifugal desanding and desilting machine can replace solid control equipment such as a desander + desilter or mud cleaner, and the treatment effect is great. It is much better than the above equipment and is a new tool for controlling mud performance.

Advantages of Centrifugal Mud Cleaner

1. Low energy consumption and energy saving: no need to use 55 or 75 kW centrifugal pump drive.

2. Low equipment purchase cost: a single rotary desander can replace the desander + desilter + 1 centrifugal pump + medium speed centrifuge, and can be equipped with only 2 general performance vibrating screens, reducing equipment procurement cost and the cost is expected to be reduced by about 50%.

3. Good sand discharge effect: The sand discharge volume is large and is not affected by the performance of the mud. The effect is much better than traditional desanders, desilters, cleaners and other equipment.

4. Stable treatment effect: The motor drives the drum, and the drum drives the mud to rotate. Therefore, the rotation of the mud is not affected by mud viscosity, pump pressure, and discharge port blockage, and the treatment effect is very stable.

5. High separation efficiency: Due to the large drum, high rotation speed and thin liquid layer, the solid particles in the mud can be separated under almost exactly the same conditions.

6. It reduces the performance requirements of the vibrating screen and completely eliminates the problem of slurry running: the vibrating screen is equipped with a 20-60 mesh mesh, which can remove large particles, so that the low-cost traditional linear shale shaker can fully meet the screening requirements. , and the coarse screen has a long service life, reducing the material and labor costs of replacing the screen.

7. The solid control system can be simplified: 2 mud shale shakers + rotating desander + large-displacement high-speed centrifuge can meet all solid control needs, reduce the equipment footprint, increase the relocation speed, and also reduce the total amount of circulating mud , reduce mud costs and waste disposal costs.

8. Helps reduce the consumption of spare parts: Since the Shale Shaker can use coarse mesh, the life of the mesh is longer. It can reduce one vibrating screen, cancel the mud cleaner, and reduce two equipments that cause screen consumption. The consumption of the cyclone is avoided and one sand pump is reduced, so that the annual spare parts and maintenance costs can be reduced by about 60%.

9. Conducive to the realization of automation: the type and quantity of tank surface equipment are reduced. The operating performance of the equipment can be achieved by adjusting the speed and displacement. The vibrating screen does not need to replace screens with different mesh numbers, and remote control and automatic control can be realized. It is beneficial to reduce labor consumption and achieve safe and efficient drilling.

HMC-200 centrifugal desander and desilter technical parameters

| No. | Items | Parameters |

| 1 | Model | HMC-200 |

| 2 | Dimensions | 2330*1456*1800(LxWxH) |

| 3 | Weight (Host net weight) | 2980Kg |

| 4 | Max capacity | 200m3/h |

| 5 | Drum inner diameter | 650mm |

| 6 | Drum speed | 400-1350rpm |

| 7 | Vibration intensity | No load ≤7.1mm/s, Load≤11.2mm/s |

| 8 | Dynamic balancing accuracy level | No less than G6.3 |

| 9 | Differential oil temperature rise | No load≤30℃/h,Load≤40℃/h |

| 10 | Bearing temperature rise | No load≤30℃/h,Load≤40℃/h |

| 11 | Machine operating noise | Not greater than 90dB |

| 12 | Main motor power | 55Kw |

| 13 | Voltage/Frequency | 380V,50Hz |

| 14 | Drum material | 304 high quality stainless steel |

| 15 | Control method (optional) | Frequency conversion control/industrial frequency mechanical speed regulation/hydraulic speed regulation |