Solids Control Equipment

- Mud Shale Shaker

- Degasser

- Mud Cleaner

- Centrifuge

- Mud Agitator

- Mud Gun

- Jet Mud Mixer

- Centrifugal Pump

- Shear Pump

- Spray Pump

- Vacuum Pump

- Mud Gas Separator

- Ignition

- Drilling Cuttings Dryer

- Filter Press

- Conveyor

Drilling Tools and Spare Parts

- Mud Shale Shaker Spare Parts

- Centrifugal Pump Spare Parts

- Mud Pump Spare Parts

- Centrifuge Spare Parts

- Mud Tank Bottom Valve

- Mud Hopper

- Mud Tank Level Alarm

- Polyurethane Cyclone

- Electric Motor

- WPS Reducer

- Mud Tank Union

- Explosion-proof Water Tank Heater

Mud Treatment System

- Drilling Fluid Solids Control System

- Water-based Mud Treatment System

- Oil based Mud Treatment System

- Trenchless Mud Treatment System

- Mud Mixing System

- Drilling Fluid Cooling System

- Truck mounted Mud Circulation System

- Barite Recovery System

Tank and Steel Structure

Phone: 86-29-88680837

Mail: sales@hlsolidscontrol.com

Add: Room 804, Building 1, Western Cloud Valley Phase II, Fengxi New Town, Xixian New District, Shaanxi Province

Mud Desander

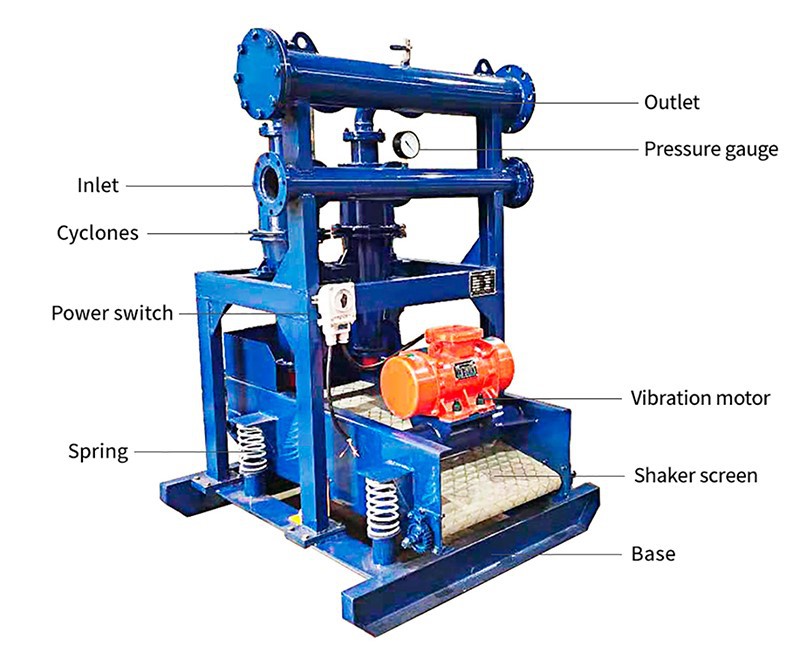

Product Overview:

1.Wear-resistant cast iron/polyurethane cyclone

2.Secondary separation vibrating screen

3.Stainless steel filter screen

4.Quick installation of screen structure

5.Explosion-proof control switch

Mud Desander Details

Mud desander is a secondary solids control system for processing drilling fluid. According to the diameter of the cyclone, it is divided into cyclone desander and cyclone desilter. Generally, cyclones above 8" are called desanders, and 8", 10", 12" cyclones are commonly used, which are mainly used to separate solid particles with a particle size of 47-76μm in the drilling fluid. According to the size of the processing capacity required by the customer, select several groups of cyclones to combine to form a desander.

Mud Desander Features

1.Wear-resistant cast iron/polyurethane cyclone

2.Secondary separation vibrating screen

3.Stainless steel filter screen

4.Quick installation of screen structure

5.Explosion-proof control switch

Mud Desander Parameters

|

Model |

HCS250S |

HCS200×2S |

HCS250×2S |

HCS300×2S |

|

Processing capacity |

50 m3/h |

100 m3/h |

200 m3/h |

240 m3/h |

|

Cyclone diameter |

250mm(10”) |

200mm(8”) |

250mm(10”) |

300mm(12”) |

|

Cyclone quantity |

1 |

2 |

2 |

2 |

|

Separation scale |

20~40μm |

20~40μm |

20~40μm |

20~40μm |

|

Motor power |

0.5 KW |

0.5 KW |

0.5 KW |

0.75 KW |

|

Application |

Wells less than 100 meters |

Horizontal directional drilling |

4000m oil drilling |

Oil drilling over 5000 meters |

|

Matched sand pump |

SB4×3-15KW |

SB5×4-22KW |

SB8×6-55KW |

SB8×6-75KW |

|

Weight |

550KG |

750KG |

800KG |

1100KG |

|

Dimensions |

1500×800×1800 mm |

1500×1200×1800 mm |

1500×1300×1800 mm |

1500×1500×1800 mm |

Desander Outside Drawing

1.shale shaker

2. base

3. Explosion-proof electric cabinet

4. pressure gage

5. pipeline

6. 10"hydrocyclones

Drilling Fluid Desander Picture

Mud Desander Delivery

2 sets of drilling desander were delivered to oilfield

Desander Installation and Debugging

Drilling desander is mainly composed of HZS vibrating screen, stents, electric cabinet, pressure gauge, manifold, and other components of the cyclone, the following graph: desander into fluid pipe and overflow pipe ends are symmetric structure, convenient in installation. The sand pump pulp out of the mouth and the desander into liquid work 6 "rubber hose connection, will overflow pipe of desilter 8" hose drainage to another drilling fluid tank.

Welcome to send inquiry to us if you have purchase request of drilling fluid desander sales@hlsolidscontrol.com