Tank and Steel Structure

- Rig Mat

- Elevated Diesel Tank

- Nested Water Tank

- Fracturing Fluid Tank

- Drilling Pipe Basket

- Drill Cuttings Box

- Mud Storage Tank

Mud Treatment System

- Drilling Fluid Solids Control System

- Water-based Mud Treatment System

- Oil based Mud Treatment System

- Trenchless Mud Treatment System

- Mud Mixing System

- Drilling Fluid Cooling System

- Truck mounted Mud Circulation System

- Barite Recovery System

Solids Control Equipment

- Mud Shale Shaker

- Degasser

- Mud Cleaner

- Centrifuge

- Mud Agitator

- Mud Gun

- Jet Mud Mixer

- Centrifugal Pump

- Shear Pump

- Spray Pump

- Vacuum Pump

- Mud Gas Separator

- Ignition

- Drilling Cuttings Dryer

- Filter Press

- Conveyor

Drilling Tools and Spare Parts

Phone: 86-29-88680837

Mail: sales@hlsolidscontrol.com

Add: Room 804, Building 1, Western Cloud Valley Phase II, Fengxi New Town, Xixian New District, Shaanxi Province

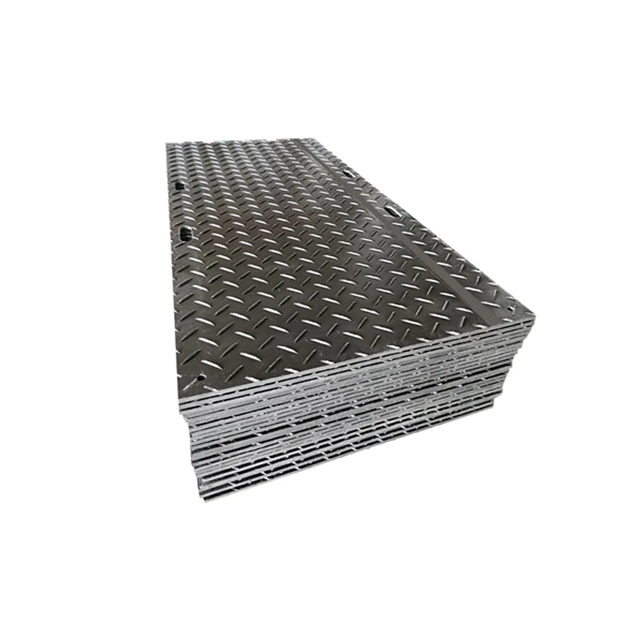

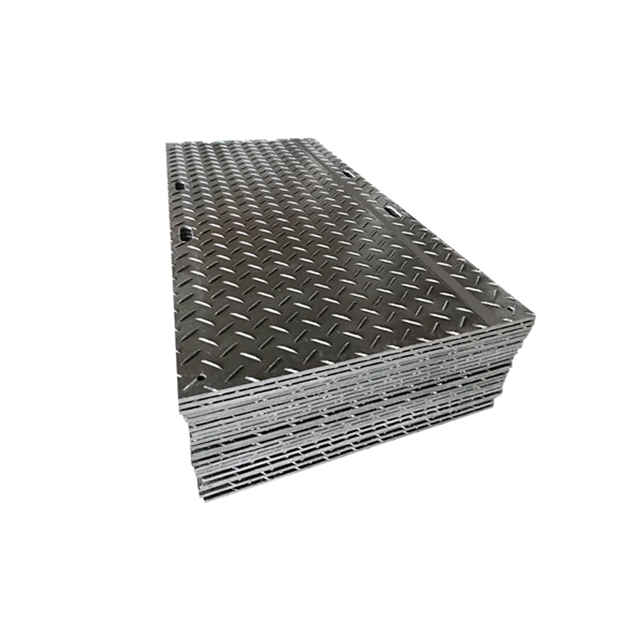

Heavy Duty Mats

Product Overview:

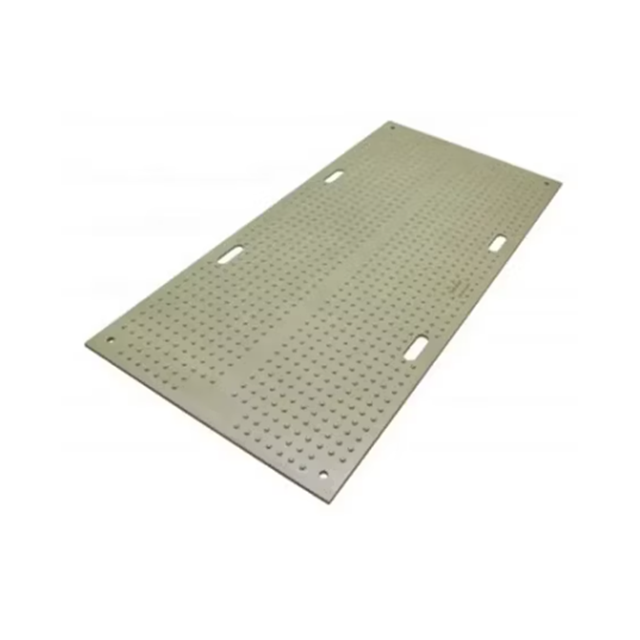

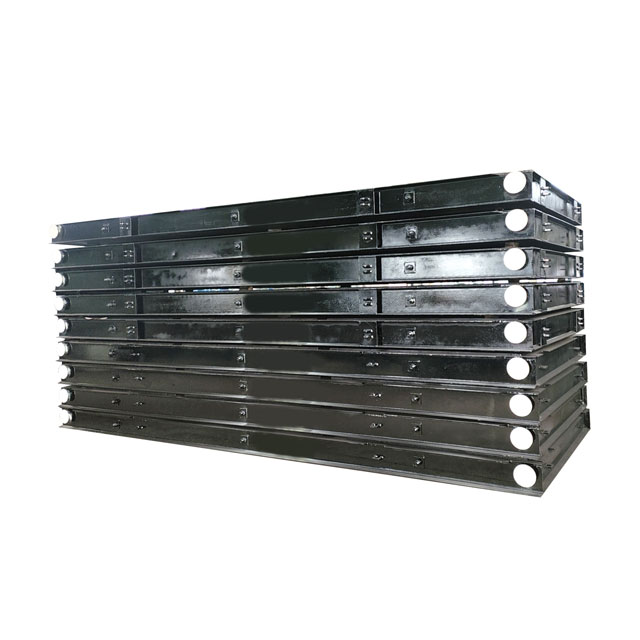

Compared with high-cost aluminum protection mats and traditional steel and wood rig matting,our Heavy Duty Mats have wider application. And due to the use of HDPE or UHMWPE materials, the mat is both environmentally friendly and economical for application. The connection methods between the matting are flexible and easy to install, making them ideal load spreading mats for construction sites, oil and gas projects, etc.

Heavy Duty Mats Details

Product Specification

|

Model |

Length |

Width |

Thickness |

Weight |

Load Capacity |

Qty in Container |

|

HXD-01 |

9.8'/3000mm |

8.2'/2500mm |

1.5''/38mm |

292kgs/ 645lbs |

150tons |

78pcs in 40ft 26pcs in 20ft |

|

HXD-02 |

13.1'/4000mm |

6.5'/2000mm |

1.5''/38mm |

312kgs/687lbs |

150tons |

80pcs in 40ft 40pcs in 20ft |

|

HXD-03 |

14.8'/4500mm |

6.5'/2000mm |

1.5''/38mm |

351kgs/774lbs |

160tons |

80pcs in 40ft 40pcs in 20ft |

|

HXD-04 |

19.7'/6000mm |

6.5'/2000mm |

1.6''/40mm |

490kgs/1080lbs |

170tons |

40pcs in 40ft 20pcs in 20ft |

How to install this heavy duty mats?

|

Step 1: Lay the first mat flat on the ground and insert one end of the connector into the hole in the corner of the mat. |

Step 2: Place the short side of the second mat against the short side of the mat already on the ground and lift it up at a 45- to 60-degree angle from the ground. Insert the other end of the connector on the already laid mat into the same hole on the second mat. Choose the appropriate connector based on the total area that the mat needs to cover. |

|

Step 3: Lay the second mat down on the ground. |

Step 4: Repeat steps 2 and 3 until all mats are connected. |

Source durabase composite mats from HL Petroleum

* The mat is resistant to breakage, corrosion, impact and aging. It is also UV-resistant and performs well in both extremely hot and cold climates, easy to install, reusable and suitable for different applications.

* The matting is non-toxic and odorless, does not cause damage to ground facilities and the environment, with high environmental value.

* The cost of the product itself and the transportation cost are lower than those of traditional mats, making it your best choice.

* HL Petroleum is your reliable supplier, with strict product quality inspections and fast delivery.