Tank and Steel Structure

- Rig Mat

- Elevated Diesel Tank

- Nested Water Tank

- Fracturing Fluid Tank

- Drilling Pipe Basket

- Drill Cuttings Box

- Mud Storage Tank

Mud Treatment System

- Drilling Fluid Solids Control System

- Water-based Mud Treatment System

- Oil based Mud Treatment System

- Trenchless Mud Treatment System

- Mud Mixing System

- Drilling Fluid Cooling System

- Truck mounted Mud Circulation System

- Barite Recovery System

Solids Control Equipment

- Mud Shale Shaker

- Degasser

- Mud Cleaner

- Centrifuge

- Mud Agitator

- Mud Gun

- Jet Mud Mixer

- Centrifugal Pump

- Shear Pump

- Spray Pump

- Vacuum Pump

- Mud Gas Separator

- Ignition

- Drilling Cuttings Dryer

- Filter Press

- Conveyor

Drilling Tools and Spare Parts

Phone: 86-29-88680837

Mail: sales@hlsolidscontrol.com

Add: Room 804, Building 1, Western Cloud Valley Phase II, Fengxi New Town, Xixian New District, Shaanxi Province

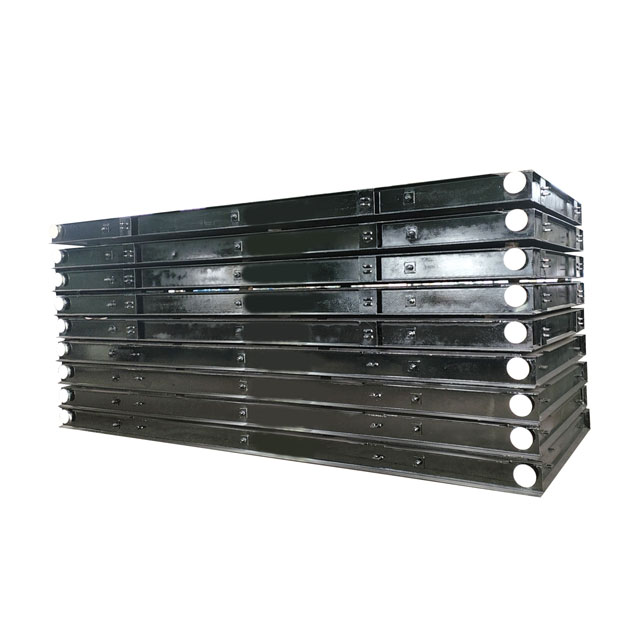

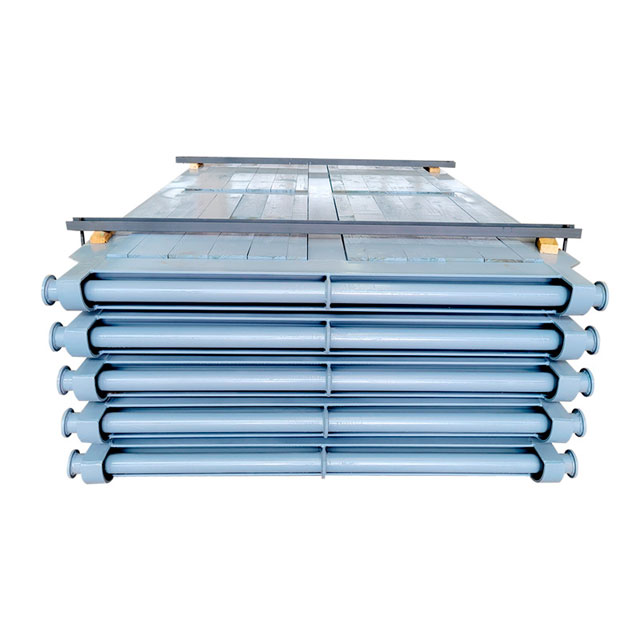

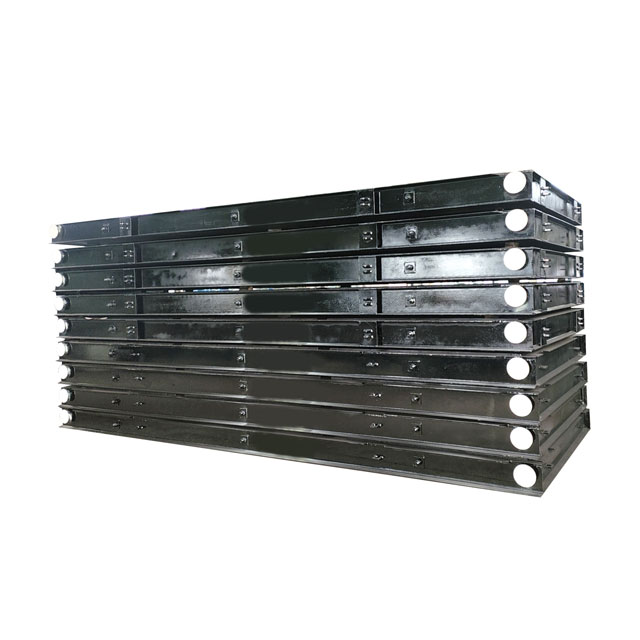

Rig Mat

Product Overview:

Drilling rig mats are a plate-shaped equipment composed of wood, steel or rubber, and is a kind of outdoor floor decoration equipment similar to floor tiles. The product has high strength, strong bearing capacity, good interchangeability, convenient transportation, low cost, convenient and quick installation, strong shock absorption, no dry cracking, no fear of water, corrosion resistance, no deformation, long service life, easy recovery and storage, etc. advantage.

Rig Mat Details

The drilling rig mats are mainly used for the equipment foundation of various drilling wellsites such as derrick base, mud pump, purification tank, power generation room, SRC room, oil tank, water tank, etc., to ensure the stability of drilling equipment for a long time.. It is suitable for ZJ20, ZJ30, ZJ40, ZJ50, ZJ70 and other types of drilling rigs at a drilling depth of 1000-7000m. The plains, plateaus, deserts, hills, beaches, swamps and other different areas of the country have greatly reduced drilling costs, improved economic benefits, replaced traditional concrete foundations, saved land, and improved on-site management.

Rig Mat Parameters

|

Model |

Length(mm) |

Width(mm) |

Height(mm) |

|

HGM204 |

2000 |

2000 |

200 |

|

HGM205 |

2500 |

2000 |

200 |

|

HGM203 |

3000 |

1000 |

200 |

|

HGM206 |

3000 |

2000 |

200 |

|

HGM209 |

3000 |

3000 |

200 |

|

HGM208 |

4000 |

2000 |

200 |

|

HGM210 |

4000 |

2500 |

200 |

|

HGM212 |

4000 |

3000 |

200 |

|

HGM216 |

4000 |

4000 |

200 |

|

HGM210 |

5000 |

2000 |

200 |

|

HGM215 |

5000 |

3000 |

200 |

Rig Mat Features

1. It is processed by embedding hard larch into the steel frame structure.

2. Timber is harder and more water-resistant than Korean pine.

3. According to the national standard GB9221-88 technology for railway sleeper timber anti-corrosion, the precision-processed and designed square timber specifications are treated with anti-corrosion treatment.

4. All steels are made of standard mould steel, and the pressure-bearing capacity and shock absorption capacity have reached the standards for use in the well site, which can completely replace the original concrete foundation structure.

5. Strong bearing capacity, high strength, strong shock absorption, no fear of water, no deformation, no cracking, corrosion resistance, good interchangeability, convenient transportation, low cost, convenient and fast installation, long service life, etc., and easy to recycle Storage, relocation of well team

6. The land can be directly replanted, and there is no problem that the land cannot be used after the well site is relocated.

7. Our company can design and produce steel and wood foundations of different specifications according to user requirements.