Solids Control Equipment

- Mud Shale Shaker

- Degasser

- Mud Cleaner

- Centrifuge

- Mud Agitator

- Mud Gun

- Jet Mud Mixer

- Centrifugal Pump

- Shear Pump

- Spray Pump

- Vacuum Pump

- Mud Gas Separator

- Ignition

- Drilling Cuttings Dryer

- Filter Press

- Conveyor

Mud Treatment System

- Drilling Fluid Solids Control System

- Water-based Mud Treatment System

- Oil based Mud Treatment System

- Trenchless Mud Treatment System

- Mud Mixing System

- Drilling Fluid Cooling System

- Truck mounted Mud Circulation System

- Barite Recovery System

Tank and Steel Structure

- Rig Mat

- Elevated Diesel Tank

- Nested Water Tank

- Fracturing Fluid Tank

- Drilling Pipe Basket

- Drill Cuttings Box

- Mud Storage Tank

Drilling Tools and Spare Parts

Phone: 86-29-88680837

Mail: sales@hlsolidscontrol.com

Add: Room 804, Building 1, Western Cloud Valley Phase II, Fengxi New Town, Xixian New District, Shaanxi Province

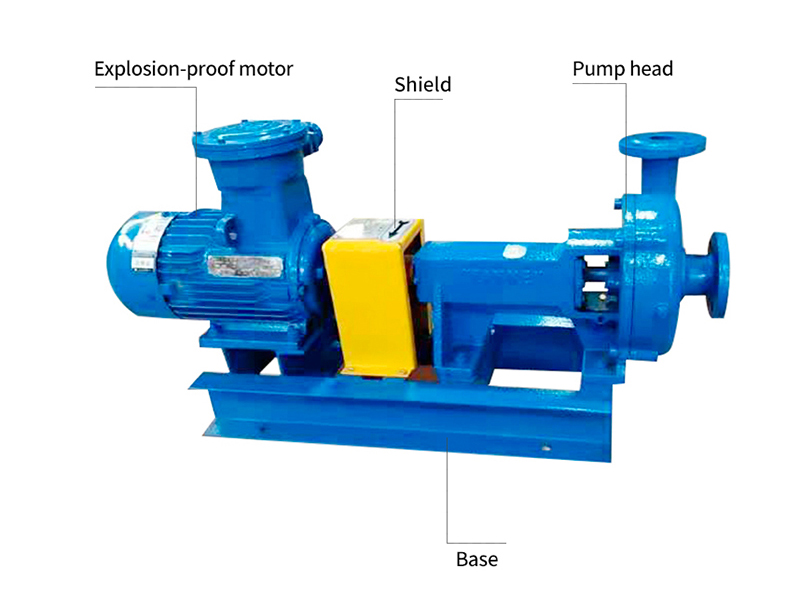

32SB180J Spray Pump

Product Overview:

32SB180J Spray pump is mainly used as supporting equipment for oil drilling mud pump. Its function is to wash and cool the cylinder liner and piston during the operation of the pump and other occasions for transporting mud.

1. Mechanical, packing double seal, no leakage

2. Compact structure, small footprint

3. Explosion-proof motor, special for oil field

4. The flow parts are made of wear-resistant cast iron with long service life

32SB180J Spray Pump Details

32SB180J Spray pump is a kind of equipment especially matched for mud pump for oil drilling, with the function of flushing and cooling sleeve and pistons in the process of pump operation, as well as include the other situation for transportation mud.

The 32SB180J spray pump is the supply pump of the mud pump, which can be driven by a motor, so it is also called an electric spray pump.

HL Spray Pump Parameters

|

Type |

Flow (m3/h) |

Lift (m) |

Efficiency (%) |

Speed (r/min) |

Power(kW) |

|

| Shaft Power | Motor Power | |||||

|

32SB180J-2.2kW |

7.5 |

10 |

48 |

1420/1750 |

0.55 |

2.2 |

|

32SB180J-4kW |

9 |

14 |

48 |

1750 |

0.93 |

3 |

|

40SB180J-3kW |

15 |

10 |

53 |

1420/1750 |

0.78 |

4 |

|

32PL |

7.5 |

10 |

48 |

1420 |

0.55 |

/ |

|

32PL(B) |

7.5 |

10 |

48 |

1420 |

0.55 |

/ |

Spray Pump Primary Structure

Spray pump is mainly composed of pump body, mechanical seal pump cover, mechanical seal, impeller, pump seat, etc. (see the figure below).

The main advantages of spray pump structure are: the main seal adopts mechanical seal, which ensures the operation without leakage. In addition, the pump has two modes of motor direct drive and pulley drive.

1.Pump body

2.Cap nut

3.Washer

4.Impeller

5.Asbestine plank

6.Mechanical seal

7.Pump cover

8.Block hydrosphere

9.Oil seal

10.Bearing cover

11.Bearing

12.Shaft

13.Nameplate

14.Pump base

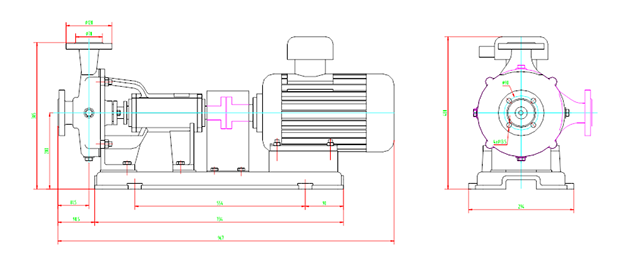

32SB180J Spray Pump Appearance Structure

32SB180J Spray Pump Pictures

Spray Pump Faults and Troubleshooting Schedule

|

S/N |

Fault |

Cause |

Troubleshooting |

|

1 |

Excessive shaft power |

1. Friction between impeller and pump base end face/mechanically real pump cover. 2. Pump operates under a condition where lift is much lower than that of the design point.

|

1. Adjust clearance between impeller and pump base end face/ mechanically real pump cover, to eliminate friction. 2. Check whether the service machine meets requirements; make opening of the drainage valve smaller, to make pump operates at the design point.

|

|

2 |

Reduced lift and flow |

1.Large particles block suction pipe and impeller flow passage 2. Lower Speed of pump 3. Worn impeller 4.Excessive clearance between impeller and pump base end face, and increased leakage 5. Too small opening of inlet valve |

1. Eliminate tamper. 2. Make pump operates at the rated speed. 3. Replace impeller. 4. Adjust clearance between impeller nd pump base end face. 5. Open inlet valve wider.

|

|

3 |

Bearing overheat |

1. Too much or little lubricant 2. Foreign substances in oil 3. Worn bearing |

1. Keep oil surface at position as specified by the oil level gauge. 2. Replace lubricant. 3. Replace bearing. |

|

4 |

Vibration and abnormal noise during pump operation |

1.Unbalanced wearing of impeller 2. Worn bearing 3. Loose connection 4. Cavitations of pump |

1. Replace impeller. 2. Replace bearing. 3. Tighten all loose parts. 4. Improve suction condition, to prevent air into pump. |

|

5 |

sealing serious leakage |

1. Seriously worn shaft sleeve . 2.Foreign substances in mechanically real assembly. 3. Mechanical seal installation skew 4.Mechanical seal worn and ineffective. |

1. Replace shaft sleeve. 2. Eliminate foreign substances and wash sealing parts. 3. Installation seal assembly again. 4. Replace mechanical seal.

|

Annotate: These pumps shall be used only within the design

Contact Us

Sales: Cici

Phone/Whatsapp/Wechat: +86-13735815206