Solids Control Equipment

- Mud Shale Shaker

- Degasser

- Mud Cleaner

- Centrifuge

- Mud Agitator

- Mud Gun

- Jet Mud Mixer

- Centrifugal Pump

- Shear Pump

- Spray Pump

- Vacuum Pump

- Mud Gas Separator

- Ignition

- Drilling Cuttings Dryer

- Filter Press

- Conveyor

Drilling Tools and Spare Parts

- Mud Shale Shaker Spare Parts

- Centrifugal Pump Spare Parts

- Mud Pump Spare Parts

- Centrifuge Spare Parts

- Mud Tank Bottom Valve

- Mud Hopper

- Mud Tank Level Alarm

- Polyurethane Cyclone

- Electric Motor

- WPS Reducer

- Mud Tank Union

- Explosion-proof Water Tank Heater

Mud Treatment System

- Drilling Fluid Solids Control System

- Water-based Mud Treatment System

- Oil based Mud Treatment System

- Trenchless Mud Treatment System

- Mud Mixing System

- Drilling Fluid Cooling System

- Truck mounted Mud Circulation System

- Barite Recovery System

Tank and Steel Structure

Phone: 86-29-88680837

Mail: sales@hlsolidscontrol.com

Add: Room 804, Building 1, Western Cloud Valley Phase II, Fengxi New Town, Xixian New District, Shaanxi Province

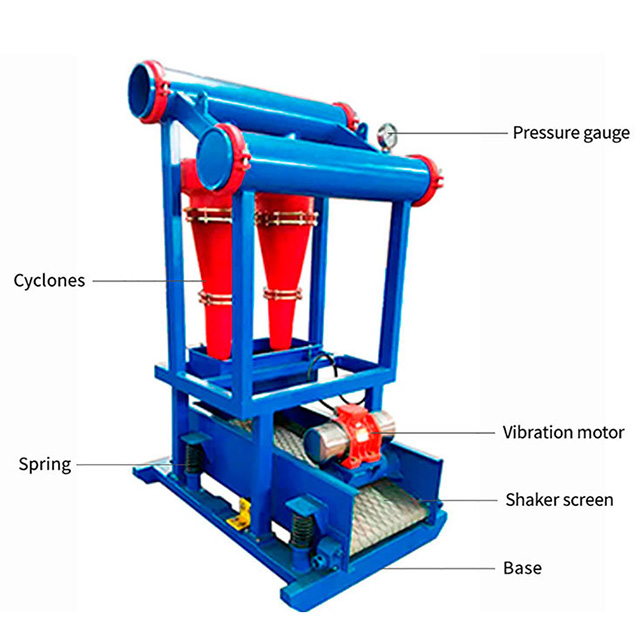

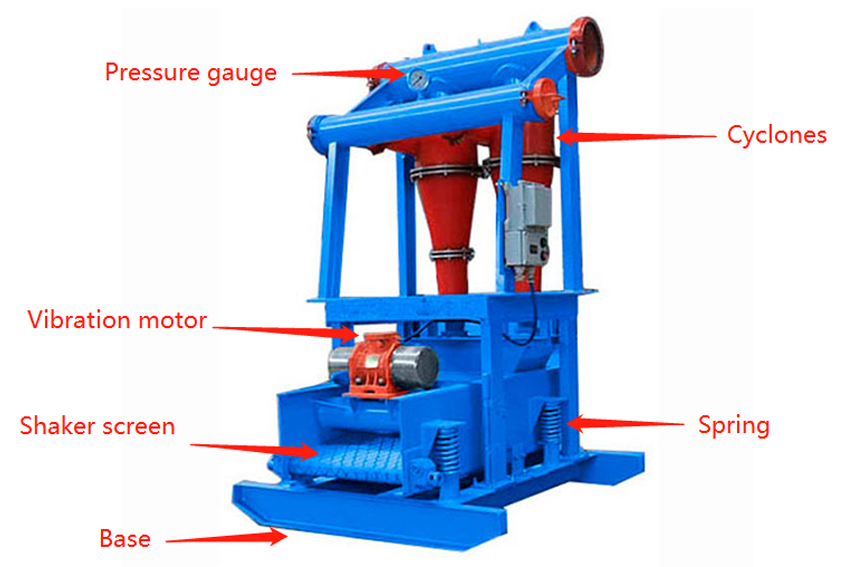

Cyclone Desander

Product Overview:

Desander is one of the important secondary solids control equipment, also known as cyclone desander, mud desander, drilling fluid desander.

1. Wear-resistant cast iron cyclone

2. Secondary separation vibrating screen

3. High quality self-vibrating motor

4. Stainless steel filter screen

5. Quick install screen mechanism

6. Explosion-proof control switch

Cyclone Desander Details

The cyclone desander is mainly used to separate the solid phase particles in the drilling fluid, ensure the stability and fluidity of the drilling fluid, improve the drilling efficiency, prevent the clogging of the drill bit, and reduce the pollution to the environment. Its technical parameters determine that it can handle a relatively large amount of drilling fluid within a certain range and achieve high separation efficiency of solid phase particles.

Cyclone Desander Working Process

1. The drilling fluid passes through the sand pump to generate a certain pressure and velocity, and enters the liquid inlet pipe of the cyclone desander.

2. Drilling fluid enters spirally along the inner wall of the cyclone to form a swirling flow. According to the size and density of the particles, under the action of centrifugal force and gravity, the coarser particles sink spirally along the inner wall of the cyclone and are discharged from the bottom flow port .

3. The finer particles spiral up along the cyclone and overflow from the overflow pipe. This part of the liquid contains smaller solid particles, and then enters the desilter of the third-stage separation equipment for further purification.

4. The discharged particles will fall on the fine mesh vibrating screen below for further separation and processing.

Cyclone Desander Parameters

|

Model |

HCS250S |

HCS200×2S |

HCS250×2S |

HCS300×2S |

|

Capacity |

50 m3/h |

100 m3/h |

200 m3/h |

240 m3/h |

|

Cyclone Diameter |

250mm(10”) |

200mm(8”) |

250mm(10”) |

300mm(12”) |

|

Cyclone Quantity |

1 |

2 |

2 |

2 |

|

Separation Particle Size |

44~74μm |

44~74μm |

44~74μm |

44~74μm |

|

Motor Power |

0.5 KW |

0.5 KW |

0.5 KW |

0.75 KW |

|

Applicable Field |

Wells less than 100 meters |

Horizontal Directional Drilling |

4000m oil drilling |

Oil drilling above 5000 meters |

|

Supporting Sand Pump |

SB4×3-15KW |

SB5×4-22KW |

SB8×6-55KW |

SB8×6-75KW |

|

Weight |

550KG |

750KG |

800KG |

1100KG |

|

Dimension: L×W×H |

1500×800×1800 mm |

1500×1200×1800 mm |

1500×1300×1800 mm |

1500×1500×1800 mm |

According to the customer's requirements for processing capacity, multiple sets of cyclones can be selected to combine into a desander to meet the needs of drilling fluid treatment.

The cyclone desander is suitable for various oil drilling rigs, such as ZJ70, ZJ50 and ZJ40, and can be used in conjunction with the closed circulation system of drilling fluid. In addition to the application in oil and gas field drilling, the desander is also widely used in mud purification in other projects, such as trenchless horizontal drilling, geothermal drilling, diaphragm wall engineering, piling and shield engineering, etc.