Mud Treatment System

- Drilling Fluid Solids Control System

- Water-based Mud Treatment System

- Oil based Mud Treatment System

- Trenchless Mud Treatment System

- Mud Mixing System

- Drilling Fluid Cooling System

- Truck mounted Mud Circulation System

- Barite Recovery System

Solids Control Equipment

- Mud Shale Shaker

- Degasser

- Mud Cleaner

- Centrifuge

- Mud Agitator

- Mud Gun

- Jet Mud Mixer

- Centrifugal Pump

- Shear Pump

- Spray Pump

- Vacuum Pump

- Mud Gas Separator

- Ignition

- Drilling Cuttings Dryer

- Filter Press

- Conveyor

Drilling Tools and Spare Parts

- Mud Shale Shaker Spare Parts

- Centrifugal Pump Spare Parts

- Mud Pump Spare Parts

- Centrifuge Spare Parts

- Mud Tank Bottom Valve

- Mud Hopper

- Mud Tank Level Alarm

- Polyurethane Cyclone

- Electric Motor

- WPS Reducer

- Mud Tank Union

- Explosion-proof Water Tank Heater

Tank and Steel Structure

Phone: 86-29-88680837

Mail: sales@hlsolidscontrol.com

Add: Room 804, Building 1, Western Cloud Valley Phase II, Fengxi New Town, Xixian New District, Shaanxi Province

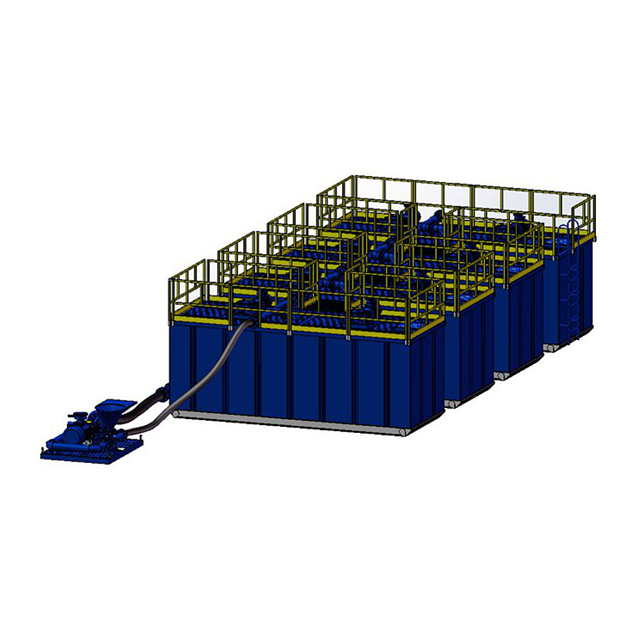

Jet Mixing System

Product Overview:

The main function of the HMM mud mixing system is to make mixing slurry. The principle of the mixing system is jet mixing and impeller mixing at the same time. The characteristics of the mixing system are full mixing, fast speed, and each mud making is completed within 15 minutes. It is widely used in geological drilling, oil drilling, and trenchless pipeline construction.

Combination of Venturi tube and jet nozzle, high slurry mixing efficiency and full mixing.

Large processing volume, fast time and labor saving.

Safe and reliable performance, easy to transport.

The tank body adopts corrugated structure, high strength, strong and durable.

Jet Mixing System Details

The main function of the HMM jet mixing system is to make mixing slurry. The principle of the mixing system is jet mixing and impeller mixing at the same time. The characteristics of the mixing system are full mixing, fast speed, and each mud making is completed within 15 minutes. It is widely used in geological drilling, oil drilling, and trenchless pipeline construction.>>Send an Enquiry sales@hlsolidscontrol.com<<

Our company independently developed and produced a mud mixing system specially designed for drilling and non-excavation construction. This product has been used by many construction units and has been used by many construction units since it was developed and put on the market and has been unanimously praised. It highlights its characteristics: low input power, Large output torque, large volume and uniform mixing, good effect, beautiful appearance and convenient transportation. It is the best supporting equipment for ideal construction.>>Send an Enquiry sales@hlsolidscontrol.com<<

The shape of the mud tank body is made of corrugated structural steel plate and section steel welding. It is strong and not easy to deform, and can withstand large tension. The bottom is made of channel steel, the upper is made of anti-skid net plate as the pedal, and the upper and lower boxes are equipped with ladders, which guarantees the advantages of safety, convenience, and long service life. The top of the tank is equipped with a mud mixer, a mud gun in the tank, and a jet mixing device on the side of the tank. Factory direct sales have price advantages and provide you with satisfactory after-sales technical services. Using our products will bring you efficiency and benefits.>>Send an Enquiry sales@hlsolidscontrol.com<<