Mud Treatment System

- Drilling Fluid Solids Control System

- Water-based Mud Treatment System

- Oil based Mud Treatment System

- Trenchless Mud Treatment System

- Mud Mixing System

- Drilling Fluid Cooling System

- Truck mounted Mud Circulation System

- Barite Recovery System

Solids Control Equipment

- Mud Shale Shaker

- Degasser

- Mud Cleaner

- Centrifuge

- Mud Agitator

- Mud Gun

- Jet Mud Mixer

- Centrifugal Pump

- Shear Pump

- Spray Pump

- Vacuum Pump

- Mud Gas Separator

- Ignition

- Drilling Cuttings Dryer

- Filter Press

- Conveyor

Drilling Tools and Spare Parts

- Mud Shale Shaker Spare Parts

- Centrifugal Pump Spare Parts

- Mud Pump Spare Parts

- Centrifuge Spare Parts

- Mud Tank Bottom Valve

- Mud Hopper

- Mud Tank Level Alarm

- Polyurethane Cyclone

- Electric Motor

- WPS Reducer

- Mud Tank Union

- Explosion-proof Water Tank Heater

Tank and Steel Structure

Phone: 86-29-88680837

Mail: sales@hlsolidscontrol.com

Add: Room 804, Building 1, Western Cloud Valley Phase II, Fengxi New Town, Xixian New District, Shaanxi Province

Drilling Fluid Mixing Systems

Product Overview:

* Fast mud mixing speed and large mixing volume.

* Each tank can work separately to configure and store different types of mud.

* Customized mixing tank size, structure and tank accessories.

* Meet the needs of various projects, including oil and gas, geothermal drilling, trenchless,etc.

Drilling Fluid Mixing Systems Details

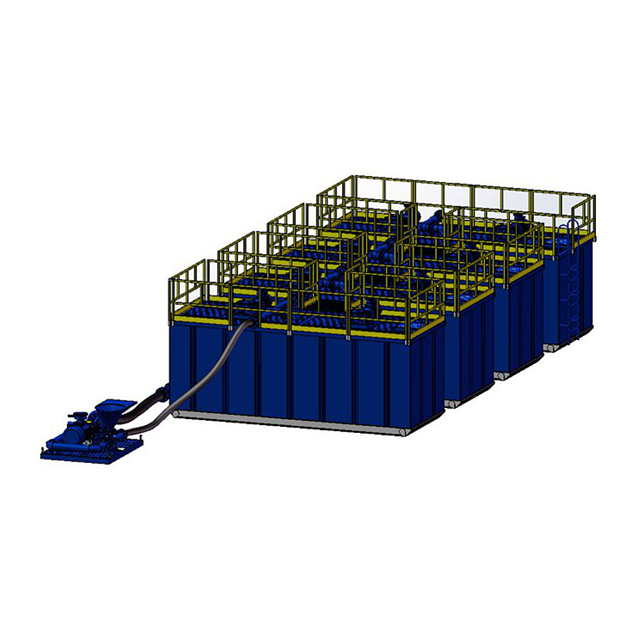

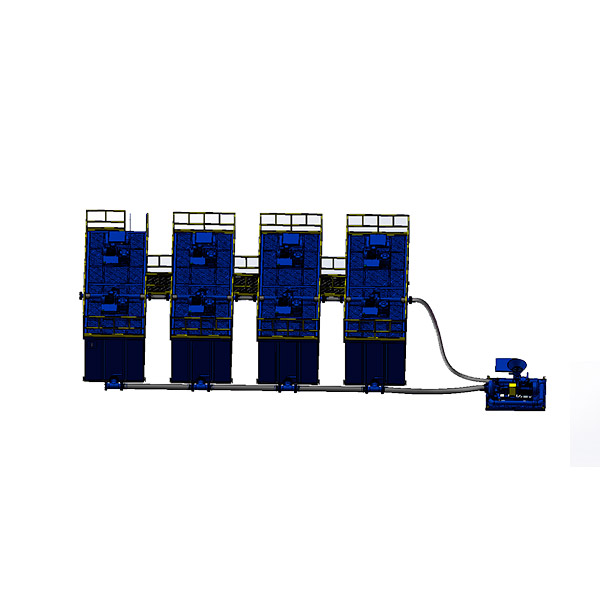

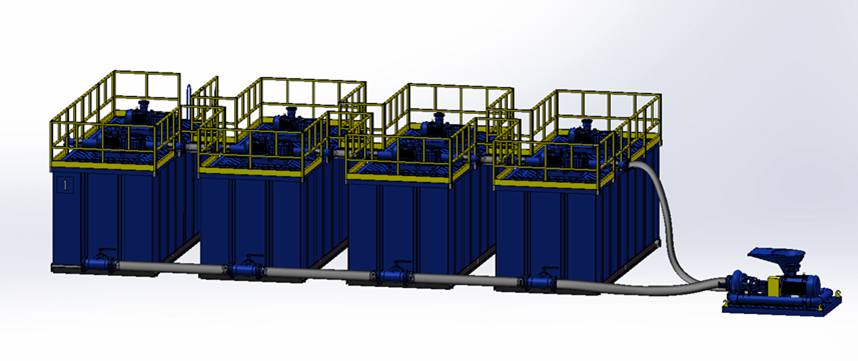

The drilling fluid mixing system produced by HL Petroleum mainly consists of several mud tanks with mud agitators. The tanks are connected in parallel through rubber hoses and each can be used separately through valves. The jet mud mixing device can be connected to one of the tanks, or it can suck mud from any tank and discharge the mixing mud into any tank. Each tank is equipped with an electric control cabinet, which can realize the separate use and storage of different types of mud in each tank. For projects with complex geological conditions that require different types of mud, the HMM series mud mixing system can realize rapid conversion of mud.

Here is a set of 100m³ mud mixing system HMM100 designed by HL Petroleum for an oilfield client.

The system includes 2 parts,

1. Jet mixer. It includes 2 jet mixing devices. Each mud mixing device is composed of a high-efficiency 37KW centrifugal sand pump and a 6-inch jet hopper, the processing capacity is 120m³/h. The drilling fluid additive and the mud to be treated are mixed firstly by jet principle.

2. 100m³ mud mixing tank. This part consists of 4 standard skid-mounted corrugated structure tanks, each equipped with 2sets of 7.5KW double-layer mud agitators, and explosion-proof lighting fixtures on the top. The double-layer impeller of the agitator and mixer is used to fully mix the mud treated by the jet mixer. The 4 tanks are fixed in parallel with rubber hoses, and each tank is equipped with an electric control box, which can achieve separate mixing and storage of different types of mud in each tank.

The Features of HL Petroleum HMM series drilling fluid mixing systems:

* The size and structure of mud mixing tanks are the same.

* Fast mud mixing speed, and the mixing volume is large.

* The mud tanks adopt a skid-mounted corrugated structure with high strength and durability.

* According to the application environment, explosion-proof electric control boxes and lighting can be provided.

* Customized services are provided. The tank size,pipeline connection,tank structure,related tank accessories,etc. are designed according to your needs.

* Sandblasting process,spraying corrosion-resistant paint.

HL Petroleum specializes in the development and production of mud handling equipment and mud systems.

We tailor-make high-quality mud mixing systems for you. Get solutions sales@hlshiyou.com