Mud Treatment System

- Drilling Fluid Solids Control System

- Water-based Mud Treatment System

- Oil based Mud Treatment System

- Trenchless Mud Treatment System

- Mud Mixing System

- Drilling Fluid Cooling System

- Truck mounted Mud Circulation System

- Barite Recovery System

Solids Control Equipment

- Mud Shale Shaker

- Degasser

- Mud Cleaner

- Centrifuge

- Mud Agitator

- Mud Gun

- Jet Mud Mixer

- Centrifugal Pump

- Shear Pump

- Spray Pump

- Vacuum Pump

- Mud Gas Separator

- Ignition

- Drilling Cuttings Dryer

- Filter Press

- Conveyor

Drilling Tools and Spare Parts

- Mud Shale Shaker Spare Parts

- Centrifugal Pump Spare Parts

- Mud Pump Spare Parts

- Centrifuge Spare Parts

- Mud Tank Bottom Valve

- Mud Hopper

- Mud Tank Level Alarm

- Polyurethane Cyclone

- Electric Motor

- WPS Reducer

- Mud Tank Union

- Explosion-proof Water Tank Heater

Tank and Steel Structure

Phone: 86-29-88680837

Mail: sales@hlsolidscontrol.com

Add: Room 804, Building 1, Western Cloud Valley Phase II, Fengxi New Town, Xixian New District, Shaanxi Province

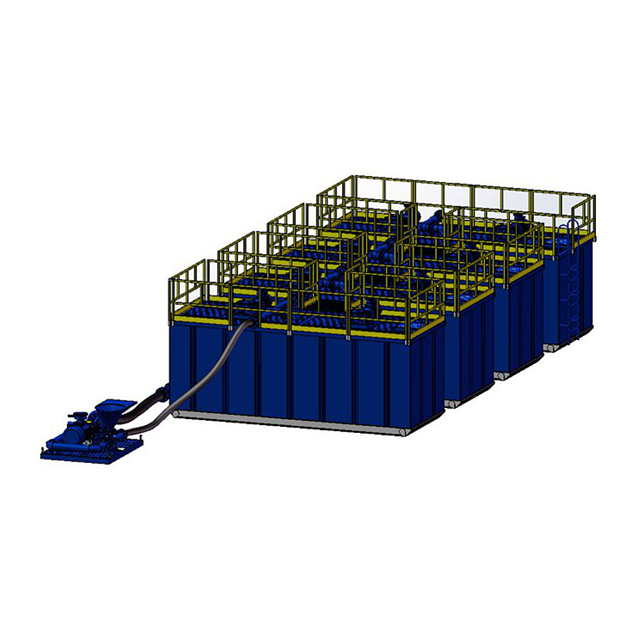

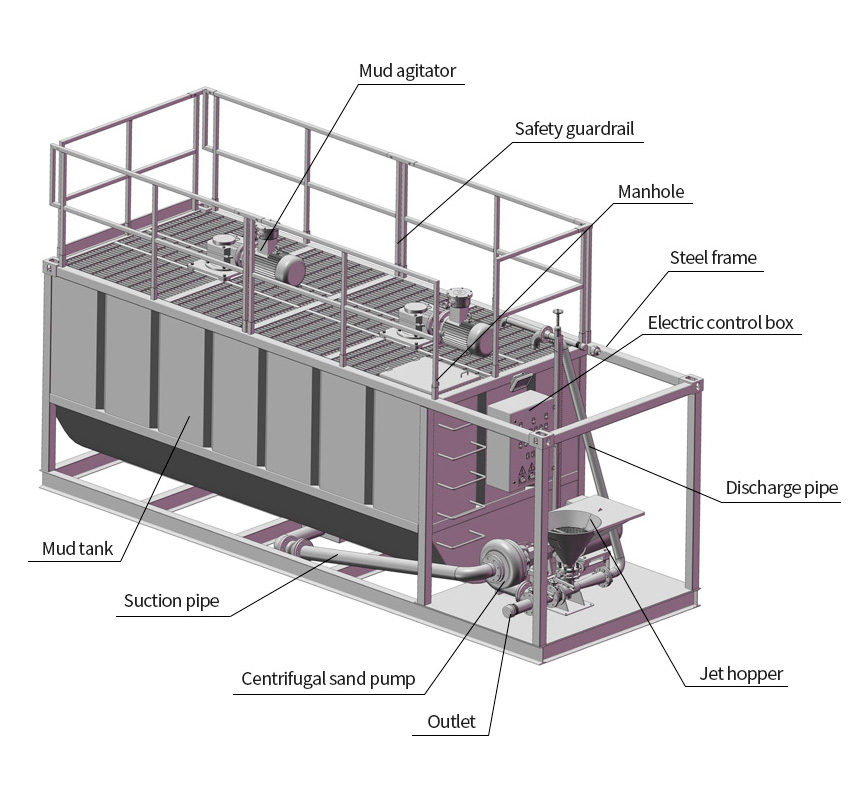

Mud Mixing System

Product Overview:

HL Petroleum mud mixing system is usually composed of four modules: jet mixer, mud mixing tank, electrical control system and lighting system. The systems can meet the mud mixing requirements of oil and gas projects, trenchless projects, and various shield construction projects. HL Petroleum designs customized solutions for you.

Mud Mixing System Details

The mud mixing system designed and manufactured by HL Petroleum is used in many drilling fluid related projects, including geothermal drilling, oil and gas field drilling and work over projects, trenchless hdd projects, road construction, etc. The drilling fluid mixing system is usually composed of four modules: jet mixing device, mud mixing tank, electrical control system and lighting system. HL Petroleum carefully designs and strictly tests each module to ensure that it can operate stably and reliably in complex and changing application environments.

During the drilling process, mud mixing and reuse are key links to ensure drilling efficiency and safety. The mixing device and mud mixing tank can quickly and evenly mix the mud, and effectively adjust the mud viscosity and ratio to meet clients' needs for drilling technology, improve drilling efficiency and engineering quality. The configuration of explosion-proof electrical control system and lighting system can provide a safe and comfortable working environment for on-site operators.

Technical Data>>Send an Enquiry sales@hlshiyou.com<<

| Model | HHX-20 | HHX-50 | HHX-100 | HHX-200 | HHX-500 |

| Mixing Capacity | 80m³/h | 120m³/h | 200m³/h | 400m³/h | 720m³/h |

| Tank Volume | 20m³ | 50m³ | 100m³ | 200m³ | 500m³ |

| Agitator Power | 7.5KW×2 | 15KW×3 | 15KW×6 | 15KW×12 | 15KW×30 |

| Jet Mixer Power | 15KW | 37KW | 55KW | 55KW×2 | 75KW×3 |

Customized service

HL Petroleum professionally customizes the mud mixing system according to the specific needs of your projects. The design will fully consider the local geological conditions and construction environment, and use materials and processes suitable for local needs to ensure the stability and durability of the system. Meanwhile, we provide comprehensive technical support and after-sales service to ensure that you can get timely and effective help and support during use.

The mud mixing system provided by HL Petroleum,

* Meets the relevant requirements of your country for this industry.

* Reasonable design and reliable performance. We listen carefully to your requirements and design the tank structure and lifting device according to the needs to facilitate transportation and movement; according to the working conditions, we equip the insulation shed and insulation pipelines, so that the mixing system can mix the slurry evenly and fully in a low temperature environment.

* Anti-corrosion and durable. Mainly reflected in the production process: high-quality steel is selected,sandblasting and rust removal treatment is carried out, and high-efficiency anti-corrosion paint is sprayed.

* One-stop procurement. All functional units and related accessories required for the mud mixing system can be directly supplied by us.

As a professional manufacturer of drilling fluid mixing systems, HL Petroleum has been committed to providing high-quality and efficient system solutions to global clients.Here are some delivered cases of HL Petroleum mud mixing system,>>Send an Enquiry sales@hlshiyou.com<<

|

Delivered on 2024,Nov. Jet mud mixing system with 10m³ mud tank, for trenchless hdd project. |

|

Delivered on 2024,Apr. |

|

|

Delivered on 2023,Oct. Small Gasoline engine mud mixing system with 3m³ mud tank, for municipal engineering project. |

| Delivered on 2023,Apr. Gasoline engine mud mixing system with 15m³ mud tank,for HDD project. |

|