Mud Treatment System

- Drilling Fluid Solids Control System

- Water-based Mud Treatment System

- Oil based Mud Treatment System

- Trenchless Mud Treatment System

- Mud Mixing System

- Drilling Fluid Cooling System

- Truck mounted Mud Circulation System

- Barite Recovery System

Solids Control Equipment

- Mud Shale Shaker

- Degasser

- Mud Cleaner

- Centrifuge

- Mud Agitator

- Mud Gun

- Jet Mud Mixer

- Centrifugal Pump

- Shear Pump

- Spray Pump

- Vacuum Pump

- Mud Gas Separator

- Ignition

- Drilling Cuttings Dryer

- Filter Press

- Conveyor

Drilling Tools and Spare Parts

- Mud Shale Shaker Spare Parts

- Centrifugal Pump Spare Parts

- Mud Pump Spare Parts

- Centrifuge Spare Parts

- Mud Tank Bottom Valve

- Mud Hopper

- Mud Tank Level Alarm

- Polyurethane Cyclone

- Electric Motor

- WPS Reducer

- Mud Tank Union

- Explosion-proof Water Tank Heater

Tank and Steel Structure

Phone: 86-29-88680837

Mail: sales@hlsolidscontrol.com

Add: Room 804, Building 1, Western Cloud Valley Phase II, Fengxi New Town, Xixian New District, Shaanxi Province

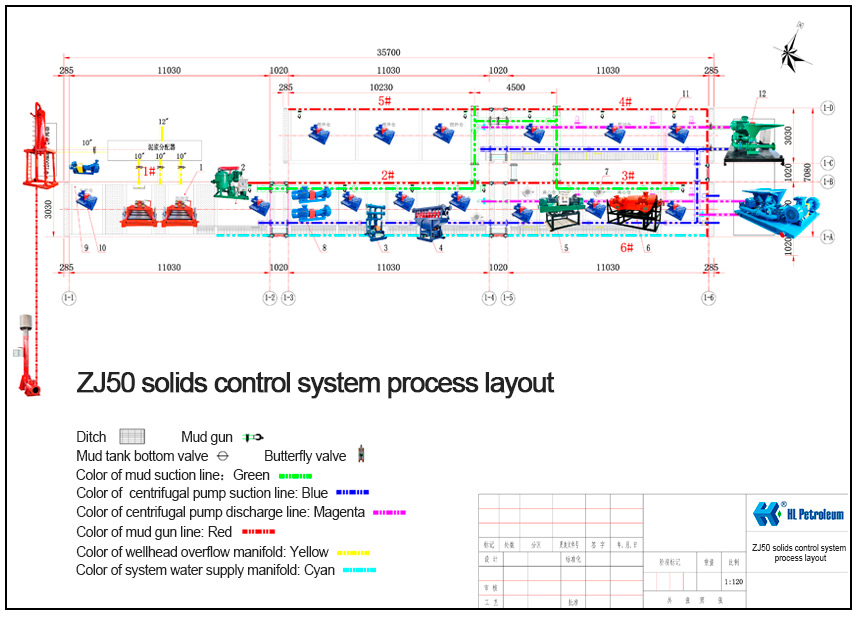

Rig ZJ50 Solids Control System

Product Overview:

1. Professional design with optimal solutions

2. Cost-effective proposal for you only

3. Reliable material with durable quality

4. Custom-built service available

5. Sufficient pre-sale and after-sale services

Rig ZJ50 Solids Control System Details

The drilling fluid solids control system mainly controls and separates the solids in the drilling fluid to achieve the recycling of the drilling fluid, also known as the mud purification system. This system plays a vital role in the oil drilling process, the core principle of the solids control system is to use a variety of physical and chemical methods to remove solid particles in the drilling fluid, such as cuttings, mud and sand, to maintain the physical and chemical properties of the drilling fluid and ensure the smooth progress of the drilling operation.

Components of Solids Control System>>Send an Enquiry sales@hlsolidscontrol.com<<

A complete solids control system including mud mixing and store units (mud tank, agitator, mud gun), solids removal units (shale shaker, hydrocyclone removal equipment, centrifuge), auiliary devices and lines.

mank tank are classified to trip tank, circulation tanks, weighting tanks,mixing tanks,stroage tanks, and etc. according to different usage.

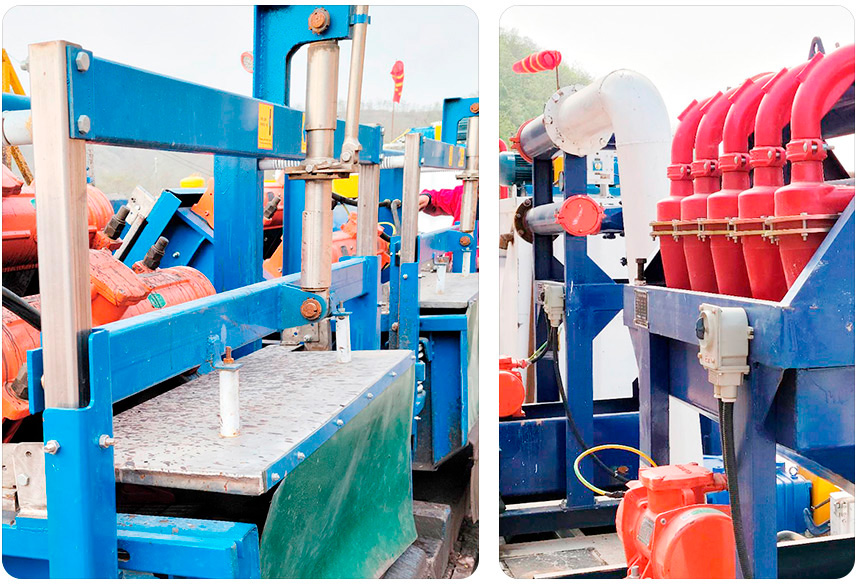

Solids removal equipment including five stage purification equipment: shale shaker, vacuum degasser, desander, desilter decanter centrifuge. mud degasser and mud desilter can be combined with shaker as mud cleaner.

Auxiliary equipment mainly mean centrifugal pumps and other accessories parts like electrial pannal and so on. According function, centrifugal pump can be used as desander pump, desilter pump, mixing pump,trip pump, and metering pump.

Rig ZJ50 Solids Control System Supporting

|

Number |

Select |

Equipment |

Parameters |

Quantity |

|

1 |

Must match |

Mud tank |

The volume is not less than 200 m3 The storage tank volume is not less than 120 m3 |

1set |

|

2 |

Mud shale shaker |

Processing capacity is not less than 181.5m3/h |

2sets |

|

| 3 | Degasser | Processing capacity is not less than 181.5 m3/h | 1set | |

|

4 |

Desander |

Processing capacity is not less than 181.5 m3/h |

1set |

|

|

5 |

Desilter |

Processing capacity is not less than 181.5 m3/h |

1set |

|

| 6 | Medium speed centrifuge | Capacity: 40m3 Separated particles:5μm~7μm | 1set | |

|

7 |

Jet mud mixer |

Sand pump capacity:200m3/h;Sand pump lift:36 m |

1set |

|

|

8 |

Shear pump |

Capacity:155 m3/h Lift:32 m |

1set |

|

|

9 |

Feeding pump |

Capacity:150 m3/h Lift:28 m |

1set |

|

|

10 |

Optional |

High speed centrifuge |

Capacity: 40m3/h Separated particles:3μm~5μm |

1set |

Working Procedure Of Solids Control System>>Send an Enquiry sales@hlsolidscontrol.com<<

-

Drilling mud from drill hole will feeding into shale shaker buffer box by pipeline, the shaker can install shaker screen mesh API 35 to API 120 to separate larger drilling cuttings. Fluids part will drop into sand trap through mesh screen.

-

Mud from sand trap will over flow into next compartment and vacuum degasser will suction mud to degasser and treated mud will overflow into degasser compartment.

-

Desander feeding pump will pick up mud from degasser compartment and feed into desander cyclone for 47 – 76 micron separation. Solids part will drop from desander nozzle and fluids over flow into desander compartment.

-

Another will pick up mud from desander compartment and feed desilter cyclone, solids part drop through desilter nozzle and fluids over flow into desilter compartment.

-

A slurry pump or screw pump then pick up mud from desilter compartment into decanter centrifuge for 2 – 7 micron separate and clean mud flow into centrifuge compartment.

-

All tank compartments after desilter compartment we name as clean mud, mixing pump can suction or discharge to any of the clean mud tank for mud transfer or new mud mixing.

-

Mud pump suction line arrange in all clean mud tank with valve.

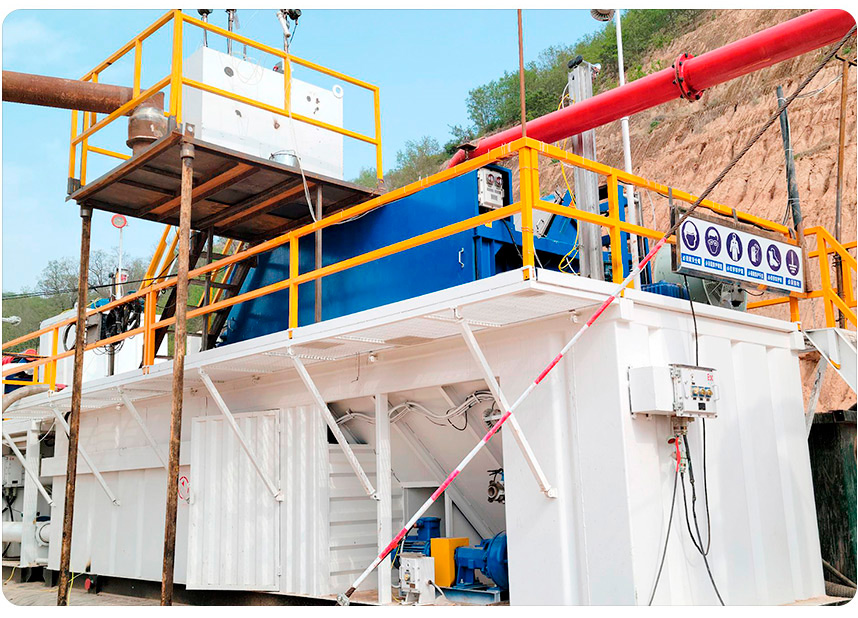

The solid control system produced by HL is simple in structure and practical. According to the drilling rig supporting requirements provided by customers, we have designed a reasonable solution to enable it to handle mud efficiently and reasonably. The tank body is surrounded by cold-pressed corrugated sheets, which makes it high-strength and beautiful in appearance, suitable for various occasions. The bottom surface of the tank is processed with inclined paving, which is convenient for cleaning sediments. The tank bottom adopts a skid-mounted design, and the position between the tanks can be quickly installed on site, which improves the installation efficiency. >>Send an Enquiry sales@hlsolidscontrol.com<<

The tank surface adopts serrated hot-dip galvanized steel grating or fiberglass anti-skid plate, and seamless square tube frame is used around it, making it more sturdy and durable. The installation of tank surface equipment is designed with limited position fixing devices, and the equipment installation is simple and convenient. The layout of the manifold in the tank is reasonable, and the flow of the mud pipeline can be controlled by valves, making the flow smooth and efficient. In terms of safety, we also equipped the equipment with guardrails and walkways, and no disassembly is required, which is convenient for transportation and installation. The solid control system produced by HL is not only simple in structure, but also fully functional, with the advantages of high strength, beauty, practicality, and efficiency, which can meet the various needs of customers.