Solids Control Equipment

- Mud Shale Shaker

- Degasser

- Mud Cleaner

- Centrifuge

- Mud Agitator

- Mud Gun

- Jet Mud Mixer

- Centrifugal Pump

- Shear Pump

- Spray Pump

- Vacuum Pump

- Mud Gas Separator

- Ignition

- Drilling Cuttings Dryer

- Filter Press

- Conveyor

Mud Treatment System

- Drilling Fluid Solids Control System

- Water-based Mud Treatment System

- Oil based Mud Treatment System

- Trenchless Mud Treatment System

- Mud Mixing System

- Drilling Fluid Cooling System

- Truck mounted Mud Circulation System

- Barite Recovery System

Tank and Steel Structure

- Rig Mat

- Elevated Diesel Tank

- Nested Water Tank

- Fracturing Fluid Tank

- Drilling Pipe Basket

- Drill Cuttings Box

- Mud Storage Tank

Drilling Tools and Spare Parts

Phone: 86-29-88680837

Mail: sales@hlsolidscontrol.com

Add: Room 804, Building 1, Western Cloud Valley Phase II, Fengxi New Town, Xixian New District, Shaanxi Province

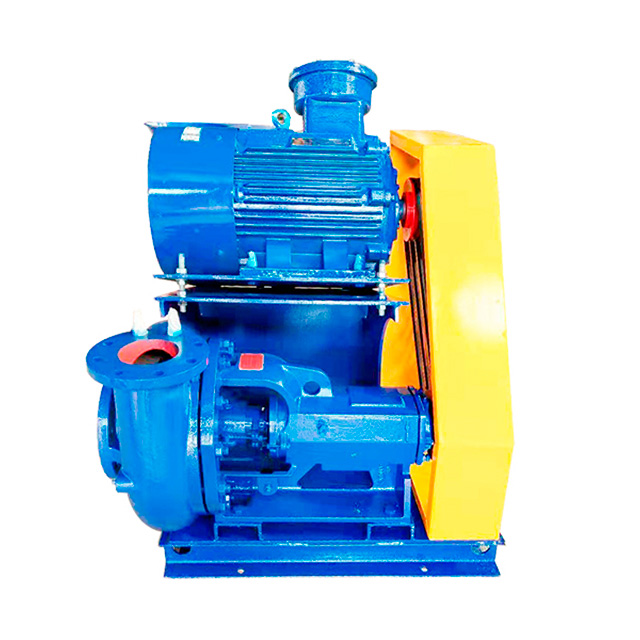

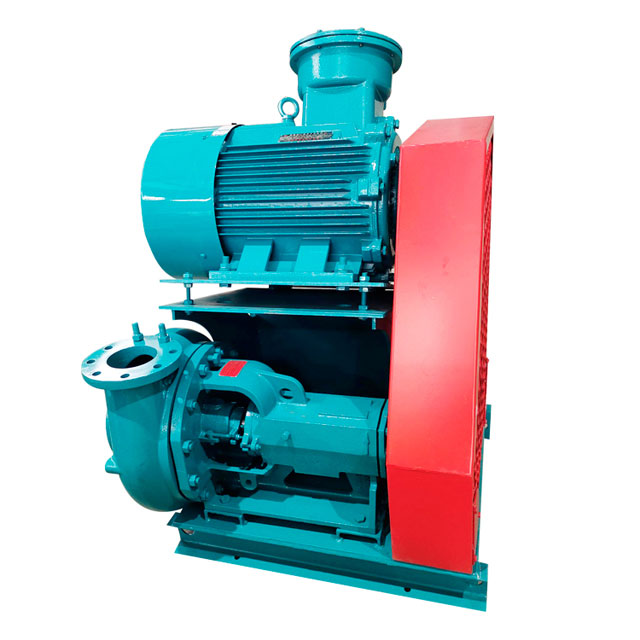

Oilfield Shear Pump

Product Overview:

1.The overall structure is compact and beautiful

2.Using special impeller and front cutting board, the cutting efficiency is greater than 95%

3.The impeller and shear pump are made of stainless steel, and the flow parts are made of high wear-resistant cast iron

4.The pump adopts mechanical seal, the service life is 6 times that of ordinary seal

Oilfield Shear Pump Details

The oilfield shear pump is a special pump for solids control drilling fluid additives. The additives used in the mud are high molecular polymers, which have high molecular weight and are difficult to hydrate when directly added. Therefore, pre-shearing of high molecular polymers is required. Oilfield shear pumps can provide high shear efficiency, accelerate the dilution and hydration process of polymers, and can also provide higher displacement and head, which can meet the requirements of preparing and processing mud.

Oilfield Shear Pump Features

1. The overall structure is compact and beautiful

2. Using special impeller and front cutting board, the cutting efficiency is greater than 95%

3. The impeller and shear pump are made of stainless steel, and the flow parts are made of high wear-resistant cast iron

4. The pump adopts mechanical seal, the service life is 6 times that of ordinary seal

Oilfield Shear Pump Parameters

|

Model |

Capacity (m3/h) |

Head (m) |

Speed (r/min) |

Efficiency (%) |

NPSH (m) |

Power(kW) |

|

| Shaft power | Motor power | ||||||

|

WJQ5×6J-75kW |

150 |

30 |

2150 |

28 |

3 |

46 |

75 |

|

WJQ5×6J-55kW |

140 |

26 |

2050 |

28 |

3 |

35 |

55 |

|

WJQ5×6J-45kW |

105 |

24 |

1750 |

28 |

2.8 |

25 |

45 |

|

WJQ5×6J-37kW |

105 |

24 |

1750 |

28 |

2.8 |

25 |

37 |

Oilfield Shear Pump Model Explanation

Shear Pump Installation Diagram

The shear pump system is formed by shear pump, mixing hopper, pipeline and polymer/clay hydrator. For installation and transportation, the polymer/clay hydrator is formed by a separate compartment.

Shear Pump Pictures

Contact us

Phone/Whatsapp/Wechat: +86-13735815206