Solids Control Equipment

- Mud Shale Shaker

- Degasser

- Mud Cleaner

- Centrifuge

- Mud Agitator

- Mud Gun

- Jet Mud Mixer

- Centrifugal Pump

- Shear Pump

- Spray Pump

- Vacuum Pump

- Mud Gas Separator

- Ignition

- Drilling Cuttings Dryer

- Filter Press

- Conveyor

Mud Treatment System

- Drilling Fluid Solids Control System

- Water-based Mud Treatment System

- Oil based Mud Treatment System

- Trenchless Mud Treatment System

- Mud Mixing System

- Drilling Fluid Cooling System

- Truck mounted Mud Circulation System

- Barite Recovery System

Tank and Steel Structure

- Rig Mat

- Elevated Diesel Tank

- Nested Water Tank

- Fracturing Fluid Tank

- Drilling Pipe Basket

- Drill Cuttings Box

- Mud Storage Tank

Drilling Tools and Spare Parts

Phone: 86-29-88680837

Mail: sales@hlsolidscontrol.com

Add: Room 804, Building 1, Western Cloud Valley Phase II, Fengxi New Town, Xixian New District, Shaanxi Province

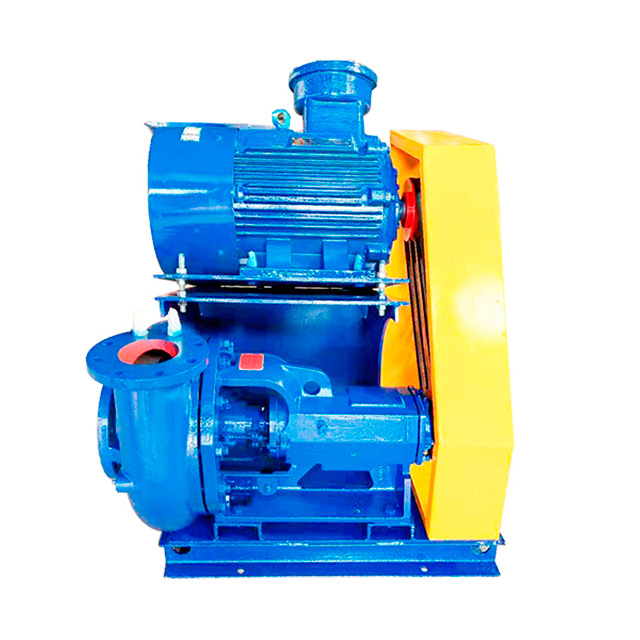

Drilling Fluid Shear Pump

Product Overview:

Xi'an HL drilling fluid shear pump is a special centrifugal pump specially used for shearing polymer and clay in oil field drilling, and it has been used on site and proved effective in theory.

Drilling Fluid Shear Pump Details

HL Petroleum drilling fluid shear pump is a special centrifugal pump specially used for shearing polymer and clay in oil field drilling, and it has been used on site and proved effective in theory.

Drilling Fluid Shear Pump Parameters

|

Model |

Capacity (m3/h) |

Head (m) |

Speed (r/min) |

Efficiency (%) |

NPSH (m) |

Power(kW) |

|

| Shaft power | Motor power | ||||||

|

WJQ5×6J-75kW |

150 |

30 |

2150 |

28 |

3 |

46 |

75 |

|

WJQ5×6J-55kW |

140 |

26 |

2050 |

28 |

3 |

35 |

55 |

|

WJQ5×6J-45kW |

105 |

24 |

1750 |

28 |

2.8 |

25 |

45 |

|

WJQ5×6J-37kW |

105 |

24 |

1750 |

28 |

2.8 |

25 |

37 |

Shear Pump Structural Drawing

1.Case 2.Impeller 3.Shear plate 4.Strengthening board 5.Cover of seal 6.Oil seal 7.Cover 8.Bearing 9.Frame 10.Bearing housing 11. Bearing 12.Luck nut 13.Lock washer 14.Oil seal 15.Shaft 16.Oil mark 17.Pipe plug 18.Mud throwing ring 19.Press plate assembly 20.O-ring 21.Stuffing 22.Pin 23.Shaft sleeve 24.Machine seal

In the drilling fluid system, the polymer (or clay) should be fully sheared in advance before entering the drilling fluid system in order to give full play to its effectiveness and improve the performance of the drilling fluid. If not fully sheared, the polymer may block the vibrating screen in the first cycle, lose a large amount of polymer, increase the drilling cost, and may also make the large-sized solid particles in the drilling fluid hard and difficult to remove. In the completion fluid, the polymer will produce many "fish eyes" due to insufficient shear. These "fish eyes" will damage the formation, reduce the permeability of the formation, and reduce the production of oil and gas layers. Facts have proved that the drilling fluid shear pump has excellent performance. It can provide a high degree of shear for the rapid hydration of polymer (or clay), and Solve the outstanding problem of poor hydration of polymer (or clay) in drilling fluid or completion fluid. At the same time, the use of drilling fluid shear pumps can reduce the amount of polymer by more than 15%, the amount of bentonite by more than 30%, and improve the loss of mud cake and fluid flow, reduce the rate of drilling fluid shear ratio, and increase the gel strength. The advanced level of similar foreign products, its shaft seal structure is more reliable, and the use and maintenance are more convenient.

Contact Us

HL solids control equipment

Phone/Whatsapp/Wechat: +86-13735815206

Mail: sales@hlsolidscontrol.com