Solids Control Equipment

- Mud Shale Shaker

- Degasser

- Mud Cleaner

- Centrifuge

- Mud Agitator

- Mud Gun

- Jet Mud Mixer

- Centrifugal Pump

- Shear Pump

- Spray Pump

- Vacuum Pump

- Mud Gas Separator

- Ignition

- Drilling Cuttings Dryer

- Filter Press

- Conveyor

Mud Treatment System

- Drilling Fluid Solids Control System

- Water-based Mud Treatment System

- Oil based Mud Treatment System

- Trenchless Mud Treatment System

- Mud Mixing System

- Drilling Fluid Cooling System

- Truck mounted Mud Circulation System

- Barite Recovery System

Tank and Steel Structure

- Rig Mat

- Elevated Diesel Tank

- Nested Water Tank

- Fracturing Fluid Tank

- Drilling Pipe Basket

- Drill Cuttings Box

- Mud Storage Tank

Drilling Tools and Spare Parts

Phone: 86-29-88680837

Mail: sales@hlsolidscontrol.com

Add: Room 804, Building 1, Western Cloud Valley Phase II, Fengxi New Town, Xixian New District, Shaanxi Province

Jet Mud Mixer

Product Overview:

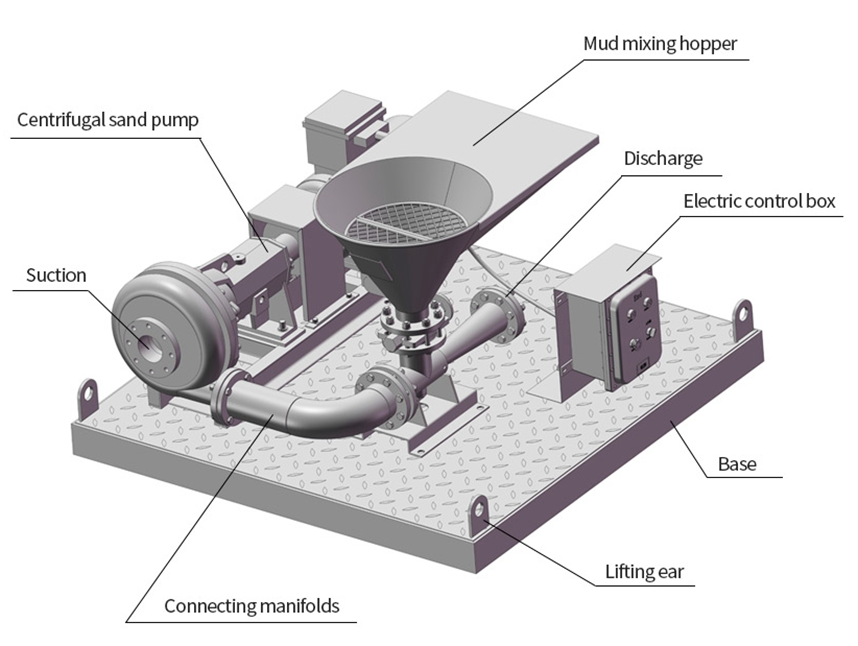

HL Petroleum manufactures HHQ series jet mud mixer,which is a type of mud mixing hopper unit used in the drilling fluids solids control system, which can meet the Aggravation and preparation of drilling fluid for the 1000m to 7000m mud systems.

Jet Mud Mixer Details

Jet mud mixer is one of the important mud handling equipment. It is an efficient and reliable professional equipment for mixing, weighting and configuring mud,which is widely used in oil and gas drilling, mining, construction engineering fields. It aims to evenly mix materials of different components to meet the specific requirements of mud performance for various engineering.

The jet mud mixing device is used to prepare or increase the total amount of drilling fluid, adjust the density, viscosity, water loss, etc. When the drilling fluid materials (bentonite, barite powder, etc.) and related chemical additives (polymers, etc.) are directly put into mud tanks, the materials and additives might be precipitated or agglomerated in large quantities, affecting the drilling efficiency and cost. The use of the jet mixer will solve this problem.

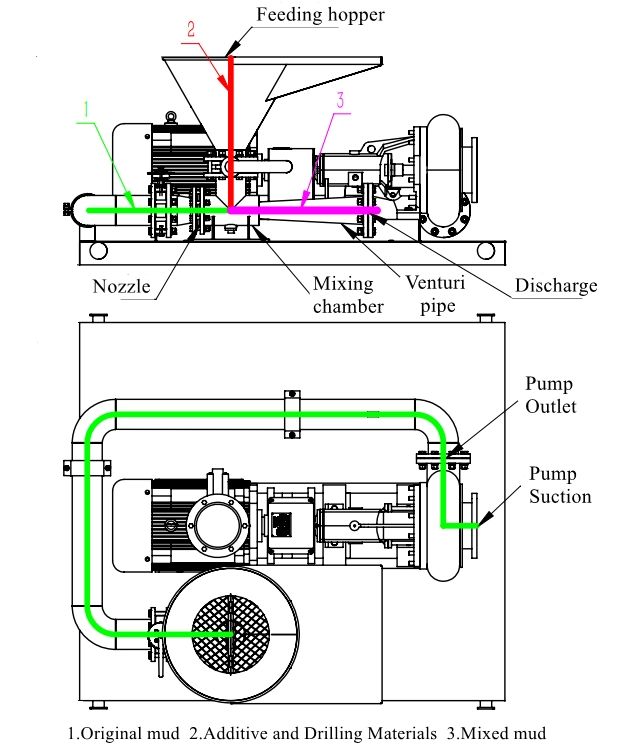

The Classic structure

Technical Data

The below are several models of jet mixers that we usually produce for clients. If you have different requirements for the size and motor power of the centrifugal pumps, or the processing capacity of the mud mixing hopper, please let us know. HL Petroleum is an OEM factory of mud mixing equipment,can produces as your demands.

>>Send an Enquiry sales@hlshiyou.com<<

|

Model |

HHQ-80 |

HHQ-100 |

HHQ-125 |

HHQ-150 |

|

Capacity |

80m³/h |

120m³/h |

180m³/h |

240m³/h |

|

Motor Power |

15KW |

30KW |

45KW |

55KW |

|

Inlet Diameter |

100mm |

125mm |

150mm |

200mm |

|

Output Diameter |

80mm |

100mm |

125mm |

150mm |

|

Nozzle Diameter |

25mm |

28mm |

32mm |

38mm |

|

Dimension |

1800×1600×1000mm |

2000×1650×1100mm |

2200×1700×1200mm |

2200×1700×1200mm |

|

Weight |

700kg |

1100kg |

1200kg |

1300kg |

Working Principle

HHQ series jet mud mixers use the working principle of jet, the high-pressure power fluid through the nozzle high-speed spray, forming a local low-pressure area, sucking the surrounding sucked materials into the mixing chamber; In the mixing chamber, the high-speed flowing power fluid and the sucked materials collide and shear violently, achieving sufficient energy exchange and material mixing; Then the mixed fluid is discharged through the venturi tube to achieve the effect of uniformly mixing the mud.

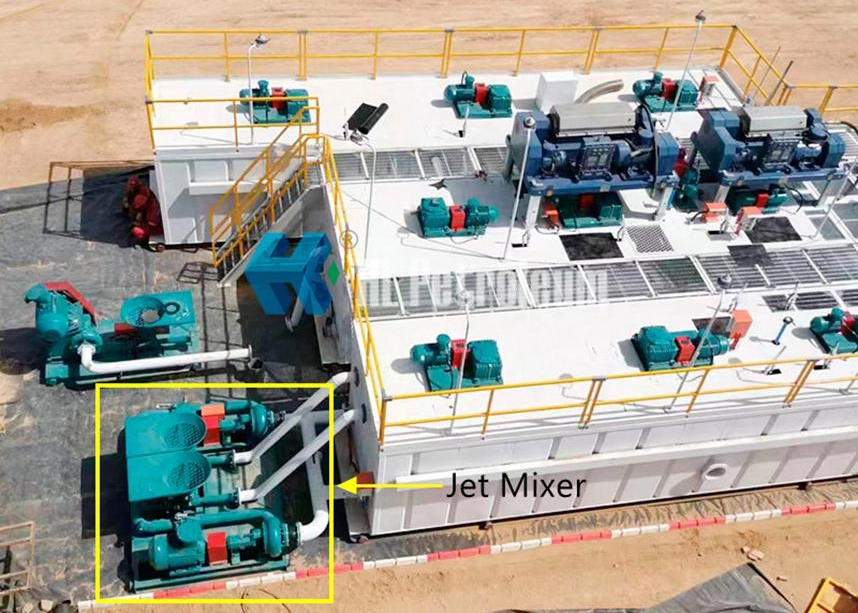

Delivered Cases

This is a delivered mud system for ZJ70 oil drilling rig. The mud handling equipment and mud tanks all are designed and manufactured by HL Petroleum. As shown in the pic, the jet mixer in the lower left corner of the picture is mainly used to configure and replenish mud, which plays an important role in stabilizing the performance of drilling fluid, saving drilling costs and improving drilling efficiency.

Why work with HL Petroleum?

HL Petroleum is professional in drilling fluids solids control equipment production, which is a high-tech manufacturer in China.It is a one-stop provider of solids control equipment and solutions. The HL quality inspection team strictly inspects each component, and after the equipment is completed, debugs the entire solids control system until the equipment can work normally. The control has also passed the product quality certification of Xi'an Bureau of Quality and Technical Supervision. It can specifically design and match different drilling rigs and solid control equipment for horizontal directional drilling rigs according to the actual needs of customers and different working conditions. It can make the entire mud purification system become a a unified whole. And provide regular maintenance, system modification, system installation and other related services to minimize drilling costs and improve your economic benefits.