Solids Control Equipment

- Mud Shale Shaker

- Degasser

- Mud Cleaner

- Centrifuge

- Mud Agitator

- Mud Gun

- Jet Mud Mixer

- Centrifugal Pump

- Shear Pump

- Spray Pump

- Vacuum Pump

- Mud Gas Separator

- Ignition

- Drilling Cuttings Dryer

- Filter Press

- Conveyor

Mud Treatment System

- Drilling Fluid Solids Control System

- Water-based Mud Treatment System

- Oil based Mud Treatment System

- Trenchless Mud Treatment System

- Mud Mixing System

- Drilling Fluid Cooling System

- Truck mounted Mud Circulation System

- Barite Recovery System

Tank and Steel Structure

- Rig Mat

- Elevated Diesel Tank

- Nested Water Tank

- Fracturing Fluid Tank

- Drilling Pipe Basket

- Drill Cuttings Box

- Mud Storage Tank

Drilling Tools and Spare Parts

Phone: 86-29-88680837

Mail: sales@hlsolidscontrol.com

Add: Room 804, Building 1, Western Cloud Valley Phase II, Fengxi New Town, Xixian New District, Shaanxi Province

Shear Mixing Device

Product Overview:

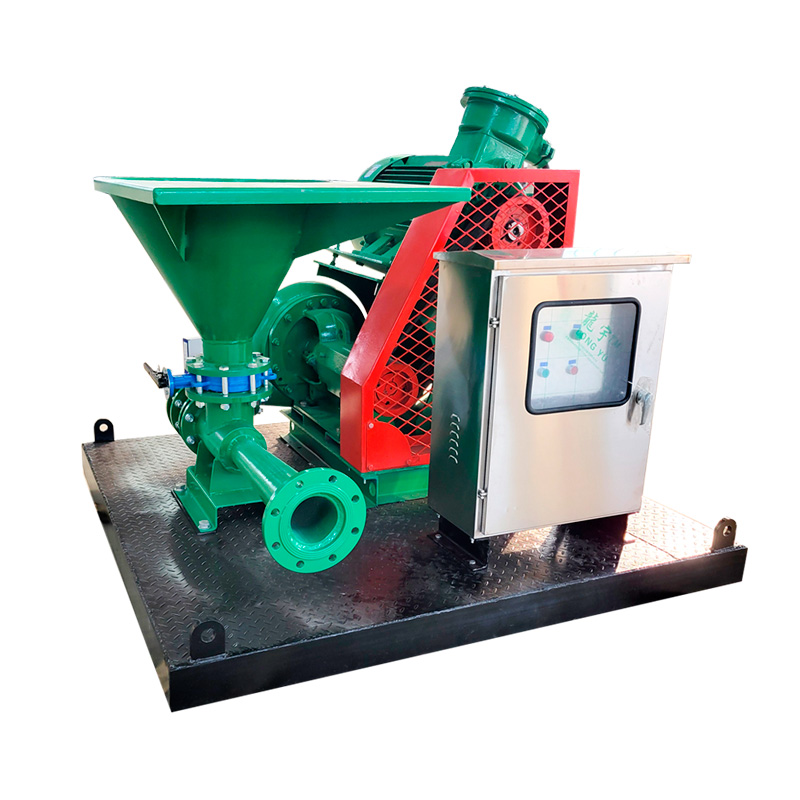

This shear mixing device is mainly composed of a shearing pump, a jet mixing hopper and manifold valves, and is equipped with a magnetic starter. The electric motors are all explosion-proof, explosion-proof grade is BT4, and the protection grade is IP55, stable performance, safe and reliable !

Shear Mixing Device Details

This shear mixing device is mainly composed of a shearing pump, a jet mixing hopper and manifold valves, and is equipped with a magnetic starter. The electric motors are all explosion-proof, explosion-proof grade is BT4, and the protection grade is IP55, stable performance, safe and reliable!

Shear mixing devices play a vital role in oilfield drilling, enabling the mixing and adjustment of drilling fluid properties to meet specific drilling requirements. They offer an effective means to enhance the quality and performance of drilling fluids, thereby improving drilling operations' efficiency.

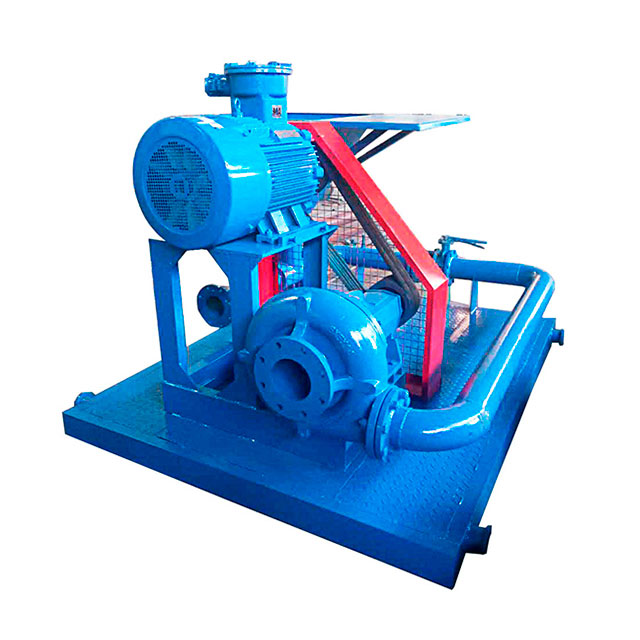

Shear Mixing Device Pictures

Shear Mixing Device Parameters

Model HHQ125-J

Supporting shear pump HJB6*5-37

Capacity 105m3/h

Inlet diameter 150mm

Outlet diameter 125mm

Nozzle diameter 28mm

Dimension 2200*1700*1200mm

Weight 1350kg

Shear Mixing Devices Features

1. Efficient Mixing: Shear devices rapidly rotate or create friction to forcefully mix solid additives or chemical agents with the drilling fluid. This efficient mixing process ensures quick and uniform dispersion of additives into the drilling fluid, ensuring homogeneity and consistency of the mixture.2. Complete Dispersion: Shear mixing devices are capable of thoroughly dispersing solid additives or chemical agents into the drilling fluid to ensure their full effectiveness. By breaking down particles or chemicals into smaller fragments, shear mixing devices increase their contact surface area with the drilling fluid, enhancing the mixing effect.

3. Rapid Reaction: Due to the high-speed rotation or frictional action of shear devices, shear mixing devices facilitate fast mixing and reaction processes within a relatively short time. This contributes to improved processing efficiency of the drilling fluid and overall drilling operations.

4. Flexibility: Shear mixing devices can be adjusted and customized to suit different needs and applications. They can accommodate various types and viscosities of drilling fluids and allow adjustments in mixing speed and duration as required.

5. Reliability: Shear mixing devices are typically made from durable materials capable of withstanding the pressure and wear caused by high-speed rotation and friction. They are well-designed to deliver stable performance and reliable operation.