Solids Control Equipment

- Mud Shale Shaker

- Degasser

- Mud Cleaner

- Centrifuge

- Mud Agitator

- Mud Gun

- Jet Mud Mixer

- Centrifugal Pump

- Shear Pump

- Spray Pump

- Vacuum Pump

- Mud Gas Separator

- Ignition

- Drilling Cuttings Dryer

- Filter Press

- Conveyor

Mud Treatment System

- Drilling Fluid Solids Control System

- Water-based Mud Treatment System

- Oil based Mud Treatment System

- Trenchless Mud Treatment System

- Mud Mixing System

- Drilling Fluid Cooling System

- Truck mounted Mud Circulation System

- Barite Recovery System

Tank and Steel Structure

- Rig Mat

- Elevated Diesel Tank

- Nested Water Tank

- Fracturing Fluid Tank

- Drilling Pipe Basket

- Drill Cuttings Box

- Mud Storage Tank

Drilling Tools and Spare Parts

Phone: 86-29-88680837

Mail: sales@hlsolidscontrol.com

Add: Room 804, Building 1, Western Cloud Valley Phase II, Fengxi New Town, Xixian New District, Shaanxi Province

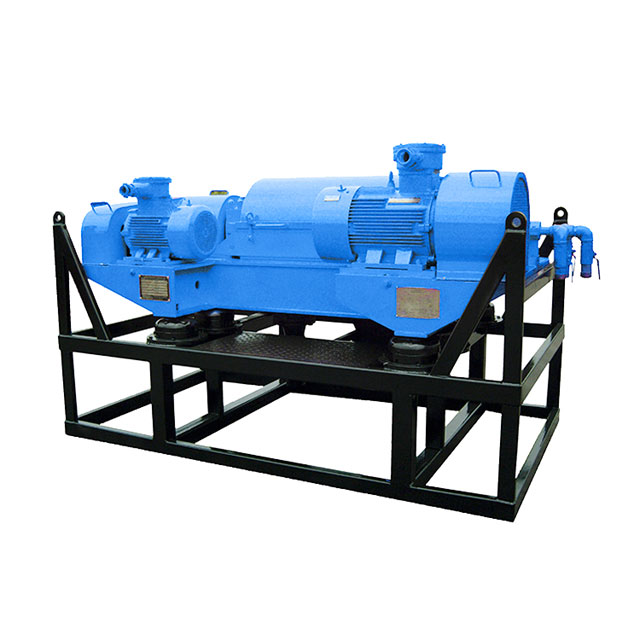

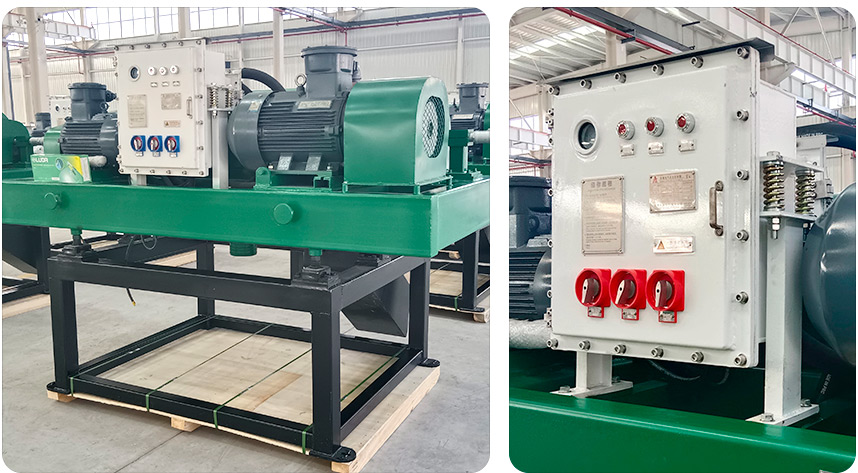

Drilling Fluid Centrifuge

Product Overview:

1).Large processing capacity

2).The core components are made of duplex stainless steel, wear-resistant and corrosion-resistant

3).Overload protection, safe operation

4).Flow control, continuous discharge

5).Explosion-proof design to adapt to harsh environments

Drilling Fluid Centrifuge Details

The Drilling Fluid Centrifuge is one of the important equipment for solid-liquid separation in solids control equipment. It is usually installed at the last stage of the solids control system to remove harmful fine solid particles such as cuttings in the mud , to ensure fast and safe drilling, or to recover valuable heavy materials such as barite, and save mud costs. According to the working speed, the centrifuges are divided into low speed centrifuges, medium speed centrifuge, and high speed centrifuges. The separation particle sizes are as follows:

Low speed centrifuge: 1500~1800RPM, separation particle size is 6~12μm

Medium speed centrifuge: 1900~2200RPM, separation particle size is 5~9μm

High speed centrifuge: 2300~3500RPM, separation particle size is: 2~7μm

>>Send an Enquiry sales@hlsolidscontrol.com<<

Technical Parameters of Drilling Fluid Centrifuge >>Send an Enquiry sales@hlsolidscontrol.com<<

|

Model |

LW355×1257-N | LW450×842-N | LW450×1000-N | LW500×1000-N | LW600×1000-N |

| Bowl Diameter(mm) | 355 | 450 | 450 | 500 | 600 |

| Bowl Length(mm) | 1257 | 842 | 1000 | 1000 | 1000 |

| Max. Capacity(m³/h) | 30 | 40 | 50 | 50 | 60 |

| Max Bowl Speed(rpm) | 3200 | 1800 | 2200 | 2500 | 1600 |

| Separation Factor | ≤2296 | ≤820 | ≤1218 | ≤1817 | ≤900 |

| Main Motor Power(KW) | 30 | 22 | 30 | 37 | 45 |

| Auxiliary Motor Power(KW) | 7.5 | 5.5 | 7.5 | 7.5 | 7.5 |

| Dimension:Lx Wx H(mm) | 3000×1500×1650 | 2370×1700×1800 | 2580×1700×1850 | 2660×1670×1760 | 3060×1870×1790 |

| Weight(kg) | 3300 | 2950 | 3300 | 3400 | 3500 |

Drilling Fluid Centrifuge Features

This series of oilfield decanting centrifugeuse a hydraulic coupling to drive the drum, adjust the spiral speed through a planetary gear differential to achieve low-speed and high-torque power transmission, and are equipped with mechanical and electrical double overload protection devices. The inner spirals are all made of cemented carbide inserts, and are designed with a special suspension structure. The blades are highly resistant to wear and the whole machine has a large processing capacity.

Drilling Fluid Centrifuge Application

There are two main reasons for using centrifuges in the drilling fluid maintenance process:

(1) Selective separation and aggravation of colloidal particles and ultrafine particles in the drilling fluid.

(2) Remove fine particles in non-aggravated drilling fluid