WhatsApp: 86-13735815206 / 86-17392256505

WeChat: 86-13735815206 / 86-17392256505

Phone: 86-29-88680837

Mail: sales@hlsolidscontrol.com

Add: Room 804, Building 1, Western Cloud Valley Phase II, Fengxi New Town, Xixian New District, Shaanxi Province

WeChat: 86-13735815206 / 86-17392256505

Phone: 86-29-88680837

Mail: sales@hlsolidscontrol.com

Add: Room 804, Building 1, Western Cloud Valley Phase II, Fengxi New Town, Xixian New District, Shaanxi Province

Main types of oilfield centrifuge

Time: 2024-05-20 Source: Solids Control Equipment Author: Mrek

The drilling fluid centrifuge has fine separation, long-term operation, easy maintenance, and efficient solid phase control. It can effectively increase the penetration rate, extend the service life of the drill bit, reduce hydraulic mechanical wear, and reduce mud costs, so it is widely used.

Drilling fluid centrifuges can be divided into two types: spiral sedimentation type and drum type according to their working principles:

The spiral sedimentation type refers to a centrifugal separator that uses centrifugal sedimentation to separate suspension components. This type of drilling fluid centrifuge has a wide range of uses. It is especially suitable for centrifugal filtration when solid particles tend to clog the filter medium and the filtration resistance is too large or when the fines are fine. Suspension separation occurs when particles are lost too much, but the moisture content of the sediment is high.

In the rotary drum centrifuge, due to the rotation of the drum, the mud rotates in the annular space between the inner and outer drums. Under the action of centrifugal force, barite and other large particles of solid matter fly to the inner wall of the outer drum and pass through an adjustable resistance. The flow nozzle is discharged, and the flow rate of the underflow can be adjusted by adjusting the opening of the choke nozzle or the pump speed. The light mud sinks slowly, enters the inner cylinder through the screen holes of the inner cylinder, and is discharged through the hollow shaft. This kind of drilling fluid centrifuge handles a large amount of mud and can recover 80% to 96% of barite.

Drilling fluid centrifuge are divided into three types: low-speed centrifuge, medium-speed centrifuge and high-speed centrifuge according to separation factors:

Low-speed centrifuge is also called "barite recovery centrifuge". Its separation factor is 500~700. For low-density solid phase, its separation point is 6~10um. For high-density solid phase, its separation point is 4~ 7um, this centrifuge is mainly used to recover barite.

The separation factor of the medium-speed centrifuge is about 800, which can separate 5~7um solid phase. It is used to remove harmful solid phases in the mud and control the specific gravity and viscosity of the mud. This is the most commonly used centrifuge in oil field drilling.

The separation factor of the high-speed centrifuge is about 1200~2100, and the separation point is 2~5um. It is used to remove harmful solid phases and control the viscosity of the mud. It is generally used in series with a low-speed centrifuge to form a double-click system. The use of a two-machine system can not only effectively remove harmful solid phases, but also prevent a large amount of barite from being wasted.

Key parameters of centrifuge

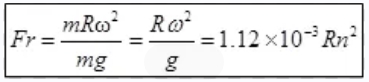

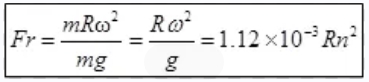

The separation factor refers to the ratio of the centrifugal force and its gravity experienced by the solid phase or suspension in the centrifugal force field in the drum, that is, the ratio of centrifugal acceleration and gravity acceleration, Fr=F centrifugal force/F gravity, which is simplified in engineering as:

Among them: R - radius of the drum, unit meter (m)

n—speed, revolution/minute (rpm)

The larger Fr, the better the separation performance of the centrifugal separator. However, for suspensions with compressible deformable filter residue, excessive Fr will block the pores of the filter residue layer and filter media, and worsen the separation effect.

HL Petroleum has more than 20 years of research, design and manufacturing experience, and we provide customers with a full range of solids control solutions. HL solid control centrifuges have complete specifications and models and support customization. The product technology is excellent and the performance is excellent. We are always committed to bringing customers a better product experience. If you are interested in our equipment, please contact us.

Drilling fluid centrifuges can be divided into two types: spiral sedimentation type and drum type according to their working principles:

The spiral sedimentation type refers to a centrifugal separator that uses centrifugal sedimentation to separate suspension components. This type of drilling fluid centrifuge has a wide range of uses. It is especially suitable for centrifugal filtration when solid particles tend to clog the filter medium and the filtration resistance is too large or when the fines are fine. Suspension separation occurs when particles are lost too much, but the moisture content of the sediment is high.

In the rotary drum centrifuge, due to the rotation of the drum, the mud rotates in the annular space between the inner and outer drums. Under the action of centrifugal force, barite and other large particles of solid matter fly to the inner wall of the outer drum and pass through an adjustable resistance. The flow nozzle is discharged, and the flow rate of the underflow can be adjusted by adjusting the opening of the choke nozzle or the pump speed. The light mud sinks slowly, enters the inner cylinder through the screen holes of the inner cylinder, and is discharged through the hollow shaft. This kind of drilling fluid centrifuge handles a large amount of mud and can recover 80% to 96% of barite.

Drilling fluid centrifuge are divided into three types: low-speed centrifuge, medium-speed centrifuge and high-speed centrifuge according to separation factors:

Low-speed centrifuge is also called "barite recovery centrifuge". Its separation factor is 500~700. For low-density solid phase, its separation point is 6~10um. For high-density solid phase, its separation point is 4~ 7um, this centrifuge is mainly used to recover barite.

The separation factor of the medium-speed centrifuge is about 800, which can separate 5~7um solid phase. It is used to remove harmful solid phases in the mud and control the specific gravity and viscosity of the mud. This is the most commonly used centrifuge in oil field drilling.

The separation factor of the high-speed centrifuge is about 1200~2100, and the separation point is 2~5um. It is used to remove harmful solid phases and control the viscosity of the mud. It is generally used in series with a low-speed centrifuge to form a double-click system. The use of a two-machine system can not only effectively remove harmful solid phases, but also prevent a large amount of barite from being wasted.

Key parameters of centrifuge

The separation factor refers to the ratio of the centrifugal force and its gravity experienced by the solid phase or suspension in the centrifugal force field in the drum, that is, the ratio of centrifugal acceleration and gravity acceleration, Fr=F centrifugal force/F gravity, which is simplified in engineering as:

Among them: R - radius of the drum, unit meter (m)

n—speed, revolution/minute (rpm)

The larger Fr, the better the separation performance of the centrifugal separator. However, for suspensions with compressible deformable filter residue, excessive Fr will block the pores of the filter residue layer and filter media, and worsen the separation effect.

HL Petroleum has more than 20 years of research, design and manufacturing experience, and we provide customers with a full range of solids control solutions. HL solid control centrifuges have complete specifications and models and support customization. The product technology is excellent and the performance is excellent. We are always committed to bringing customers a better product experience. If you are interested in our equipment, please contact us.