WhatsApp: 86-13735815206 / 86-17392256505

WeChat: 86-13735815206 / 86-17392256505

Phone: 86-29-88680837

Mail: sales@hlsolidscontrol.com

Add: Room 804, Building 1, Western Cloud Valley Phase II, Fengxi New Town, Xixian New District, Shaanxi Province

WeChat: 86-13735815206 / 86-17392256505

Phone: 86-29-88680837

Mail: sales@hlsolidscontrol.com

Add: Room 804, Building 1, Western Cloud Valley Phase II, Fengxi New Town, Xixian New District, Shaanxi Province

How to deal with the heating of the Shale Shaker bearing

Time: 2024-05-16 Source: Solids Control Equipment Author: Mrek

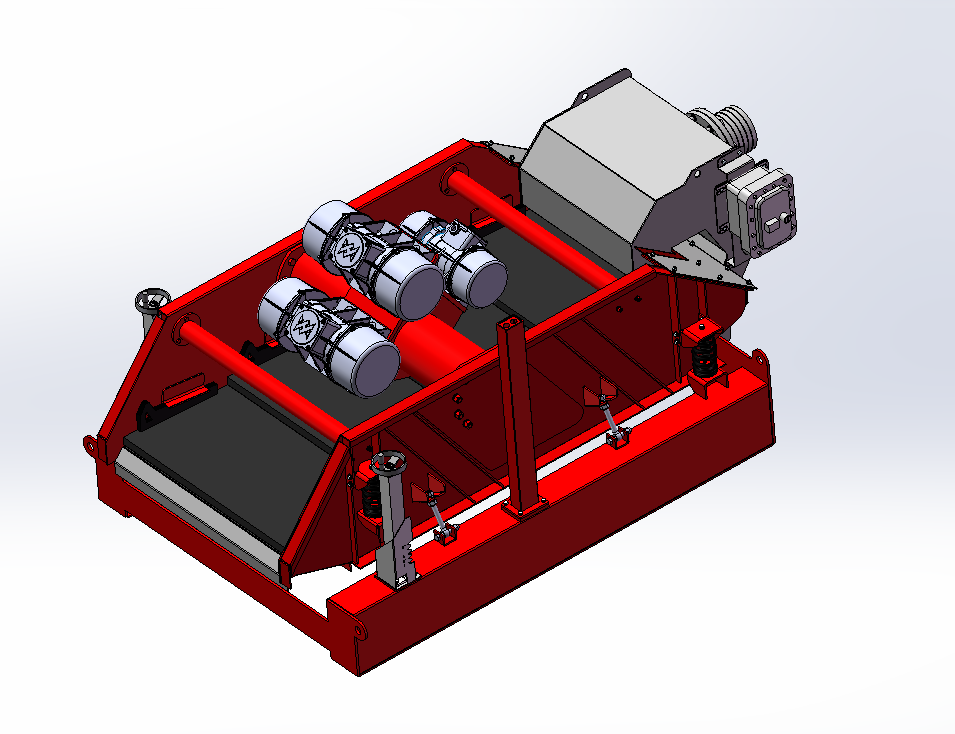

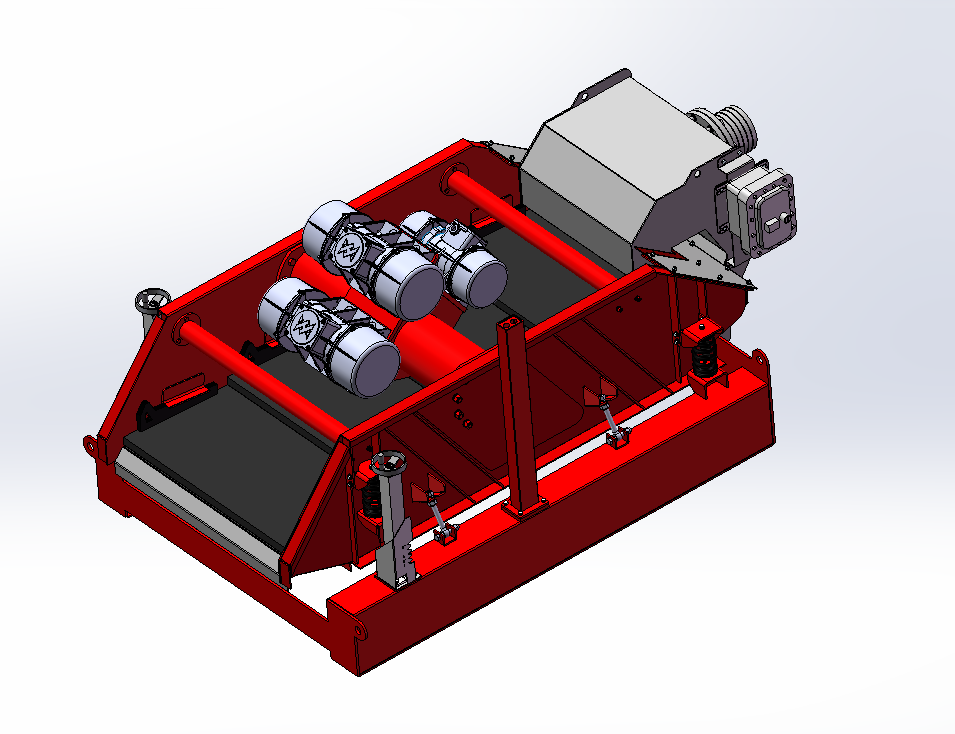

The Shale Shaker is a screening equipment that can remove mud and sand, remove the medium and sort. Its principle is to use the vibration of the screen body to make the solid phase loose, layered and screened, so as to achieve the purpose of solid-liquid separation.

When the Shale Shaker is operating normally, the bearing temperature should be maintained at 35~60℃. If the bearing temperature exceeds 60℃, the specific cause needs to be analyzed and then cooled. There are usually three reasons for abnormal temperature of the Shale Shaker bearing.

If the radial clearance of the Shale Shaker bearing is too small, it will cause the bearing wear to increase, the bearing load to increase, and the frequency to change. As a result, the temperature rises. In this case, we can use a large bearing clearance. If it is a bearing with ordinary clearance, we can grind the outer ring of the bearing to restore the bearing temperature to normal by reducing the bearing load.

Under normal circumstances, there needs to be a certain gap between the gland of the Shale Shaker and the outer ring of the bearing to ensure normal heat dissipation of the bearing and a certain axial movement. If the bearing gland is too tight, the bearing temperature will also rise. In this case, the seal between the end cover and the bearing seat can be adjusted to increase the gap, thereby effectively solving the abnormal temperature of the Shale Shaker bearing.

The Shale Shaker lubrication system can effectively eliminate friction heat, reduce friction and wear, and prevent the bearing from overheating. If the Shale Shaker bearing oil is too much or too little, the oil is contaminated or the oil quality is inconsistent, it will also cause abnormal temperature of the Shale Shaker bearing.

Therefore, during production, it is necessary to ensure the amount and quality of the Shale Shaker bearing grease. The bearing box needs to be refilled regularly according to the equipment use requirements to avoid too much or too little oil. If there is a problem with the Shale Shaker oil quality, it needs to be cleaned, replaced and sealed in time.

In the daily use of Shale Shaker, in order to avoid the occurrence of Shale Shaker failures, regular maintenance and observation of the equipment should be strengthened, problems should be discovered in time and quickly handled, so as to effectively reduce the incidence of failures.

At the same time, when purchasing Shale Shaker, attention should be paid to the model, quality and brand of the equipment, so as to effectively save costs and reduce production accidents.

HL Petroleum is a professional solids control system provider. We have more than 20 years of research, design and manufacturing experience. HL Solids Control equipment are professional, reliable, cost-effective and customizable. It is a trustworthy brand in the industry!

HL Petroleum always opens its arms to actively promote industry exchanges and promote technological development. We welcome every customer to visit, cooperate and consult.

When the Shale Shaker is operating normally, the bearing temperature should be maintained at 35~60℃. If the bearing temperature exceeds 60℃, the specific cause needs to be analyzed and then cooled. There are usually three reasons for abnormal temperature of the Shale Shaker bearing.

If the radial clearance of the Shale Shaker bearing is too small, it will cause the bearing wear to increase, the bearing load to increase, and the frequency to change. As a result, the temperature rises. In this case, we can use a large bearing clearance. If it is a bearing with ordinary clearance, we can grind the outer ring of the bearing to restore the bearing temperature to normal by reducing the bearing load.

Under normal circumstances, there needs to be a certain gap between the gland of the Shale Shaker and the outer ring of the bearing to ensure normal heat dissipation of the bearing and a certain axial movement. If the bearing gland is too tight, the bearing temperature will also rise. In this case, the seal between the end cover and the bearing seat can be adjusted to increase the gap, thereby effectively solving the abnormal temperature of the Shale Shaker bearing.

The Shale Shaker lubrication system can effectively eliminate friction heat, reduce friction and wear, and prevent the bearing from overheating. If the Shale Shaker bearing oil is too much or too little, the oil is contaminated or the oil quality is inconsistent, it will also cause abnormal temperature of the Shale Shaker bearing.

Therefore, during production, it is necessary to ensure the amount and quality of the Shale Shaker bearing grease. The bearing box needs to be refilled regularly according to the equipment use requirements to avoid too much or too little oil. If there is a problem with the Shale Shaker oil quality, it needs to be cleaned, replaced and sealed in time.

In the daily use of Shale Shaker, in order to avoid the occurrence of Shale Shaker failures, regular maintenance and observation of the equipment should be strengthened, problems should be discovered in time and quickly handled, so as to effectively reduce the incidence of failures.

At the same time, when purchasing Shale Shaker, attention should be paid to the model, quality and brand of the equipment, so as to effectively save costs and reduce production accidents.

HL Petroleum is a professional solids control system provider. We have more than 20 years of research, design and manufacturing experience. HL Solids Control equipment are professional, reliable, cost-effective and customizable. It is a trustworthy brand in the industry!

HL Petroleum always opens its arms to actively promote industry exchanges and promote technological development. We welcome every customer to visit, cooperate and consult.