Solids Control Equipment

- Mud Shale Shaker

- Degasser

- Mud Cleaner

- Centrifuge

- Mud Agitator

- Mud Gun

- Jet Mud Mixer

- Centrifugal Pump

- Shear Pump

- Spray Pump

- Vacuum Pump

- Mud Gas Separator

- Ignition

- Drilling Cuttings Dryer

- Filter Press

- Conveyor

Drilling Tools and Spare Parts

- Mud Shale Shaker Spare Parts

- Centrifugal Pump Spare Parts

- Mud Pump Spare Parts

- Centrifuge Spare Parts

- Mud Tank Bottom Valve

- Mud Hopper

- Mud Tank Level Alarm

- Polyurethane Cyclone

- Electric Motor

- WPS Reducer

- Mud Tank Union

- Explosion-proof Water Tank Heater

Mud Treatment System

- Drilling Fluid Solids Control System

- Water-based Mud Treatment System

- Oil based Mud Treatment System

- Trenchless Mud Treatment System

- Mud Mixing System

- Drilling Fluid Cooling System

- Truck mounted Mud Circulation System

- Barite Recovery System

Tank and Steel Structure

Phone: 86-29-88680837

Mail: sales@hlsolidscontrol.com

Add: Room 804, Building 1, Western Cloud Valley Phase II, Fengxi New Town, Xixian New District, Shaanxi Province

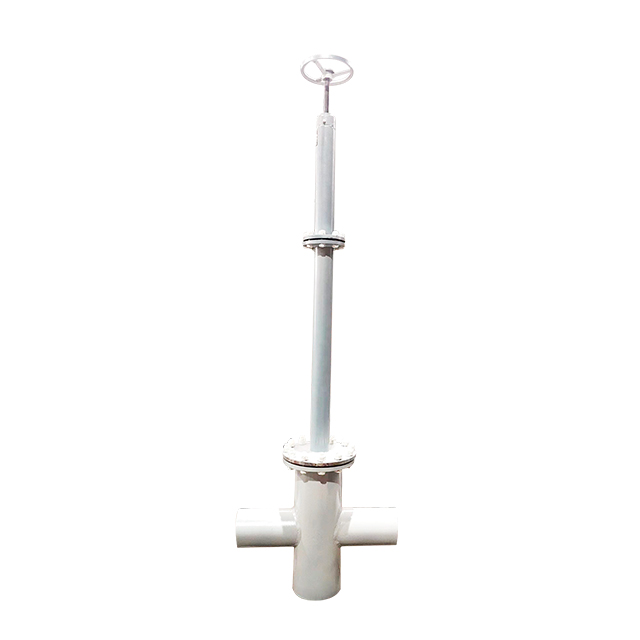

Mud Tank Valve

Product Overview:

•Flexible and labor-saving operation

•Anti-corrosion and anti-aging rubber seal

•Compact structure and simple appearance

Mud Tank Valve Details

Mud tank valve (underflow valve) is suitable for the pipeline and warehouse of the mud circulation tank with mud as the medium, as a control valve for suction and discharge, and also acts as a switch for balance control between warehouses. This valve has a compact structure and a reasonable design. It has accumulated many years of experience and switched to a valve seal, which has a longer service life and more stable performance.

Mud Tank Control Parameters

|

Product name |

Mud tank valve |

|

Model |

HDF |

|

Nominal pressure |

1.1MPa |

|

Dimensions (Inches) |

6, 8, 10, 12, 14, 16 |

|

Valve body part diameter (mm) |

325 |

|

External size (mm) |

219,273 ,325 |

The mud tank valve includes an outer pipe, a connecting rod, a connecting pipe, and a screw. The lower end of the outer pipe is connected to the connecting pipe. The connecting rod is arranged in the outer pipe. The screw is connected to the connecting rod in the outer pipe. The sealing rubber at the inner bottom end of the outer tube is connected, and the sealing rubber is sealed and fitted with the valve base. The valve base is a cone structure with an inclined surface inside. The surface of the sealing rubber and the valve base is the same inclined surface as the inclined surface of the valve base. The sealing rubber passes The upper and lower two circular metal plates are fixed; the connection part of the outer tube and the outer cylinder of the screw is above the tank surface.

The utility model improves the sealing performance of the submarine valve itself, and the conical surface sealing structure reduces the axial bearing capacity of the lifting screw to the sealing rubber by about 20%, thereby prolonging the service life of the rubber, and the connecting part of the outer tube and the outer tube of the screw Elevated above the surface of the tank to meet the requirements of quick maintenance