Solids Control Equipment

- Mud Shale Shaker

- Degasser

- Mud Cleaner

- Centrifuge

- Mud Agitator

- Mud Gun

- Jet Mud Mixer

- Centrifugal Pump

- Shear Pump

- Spray Pump

- Vacuum Pump

- Mud Gas Separator

- Ignition

- Drilling Cuttings Dryer

- Filter Press

- Conveyor

Drilling Tools and Spare Parts

- Mud Shale Shaker Spare Parts

- Centrifugal Pump Spare Parts

- Mud Pump Spare Parts

- Centrifuge Spare Parts

- Mud Tank Bottom Valve

- Mud Hopper

- Mud Tank Level Alarm

- Polyurethane Cyclone

- Electric Motor

- WPS Reducer

- Mud Tank Union

- Explosion-proof Water Tank Heater

Mud Treatment System

- Drilling Fluid Solids Control System

- Water-based Mud Treatment System

- Oil based Mud Treatment System

- Trenchless Mud Treatment System

- Mud Mixing System

- Drilling Fluid Cooling System

- Truck mounted Mud Circulation System

- Barite Recovery System

Tank and Steel Structure

Phone: 86-29-88680837

Mail: sales@hlsolidscontrol.com

Add: Room 804, Building 1, Western Cloud Valley Phase II, Fengxi New Town, Xixian New District, Shaanxi Province

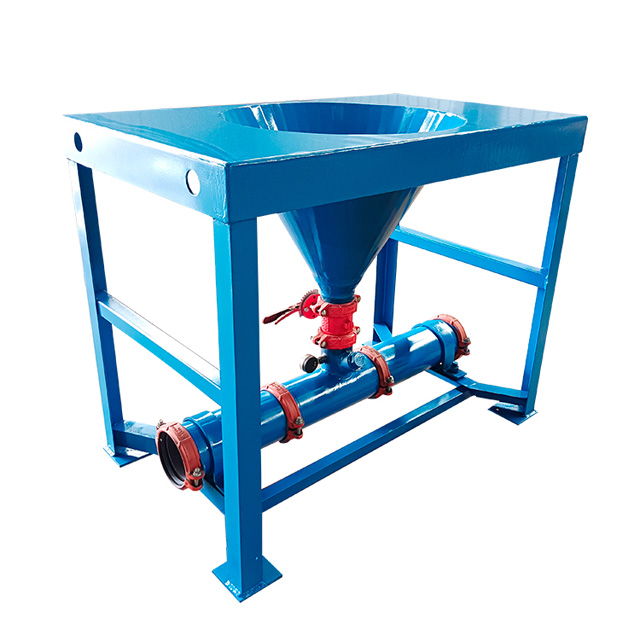

Mud Hopper

Product Overview:

Mud hopper is used to add drilling fluid materials such as bentonite and barite powder, or related chemical additives such as polymers. HL Petroleum is a leading OEM factory of mud mixing hoppers in China, feel free to contact us for details.

Mud Hopper Details

Mud hopper is used to add drilling fluid materials such as bentonite and barite powder, or related chemical additives such as polymers. HL Petroleum manufactures HLD series mud mixing hoppers for clients worldwide. HLD150 is the most widely model, with mixing capacity 240m³/h.

Work Principle

According to the jet principle. The hopper is also used for medium pressure operation.

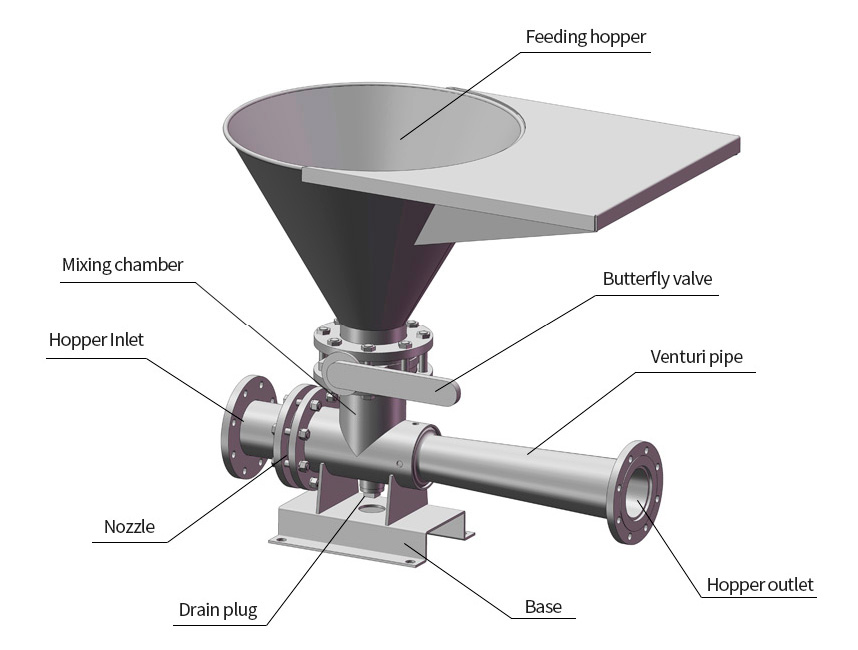

Hopper Structure

The jet hopper mainly consists of a feeding hopper, a butterfly valve, a venturi pipe, a mixing chamber and a nozzle.

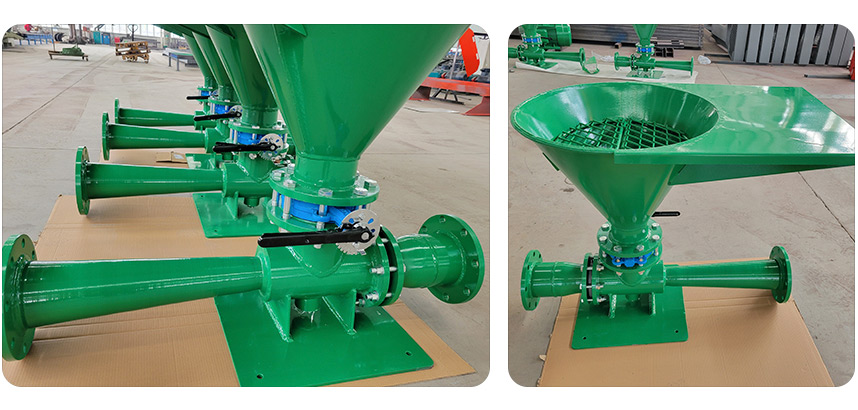

HL Petroleum mud mixing hopper pics

Technical Data

| Model | HLD-150 | HLD-150Y | HLD-150X |

| Mixing Capacity | 240m³/h | 240m³/h | 240m³/h |

| Working Pressure | 0.32~0.42MPa | 0.32~0.42MPa | 0.38~0.42MPa |

| Hopper Diameter | 700mm | 700mm | 700mm |

| Inlet Diameter | DN150(6“) | DN150(6“) | DN125(5“) |

| Out Diameter | DN150(6“) | DN150(6“) | DN150(6“) |

| Dimension | 1056×720×1032mm | 1250×750×1000mm | 1100×800×1230mm |

| Weight | 145kg | 200kg | 500kg |

OEM Service

HL Petroleum is a leading OEM factory of mud hoppers. We customize the size, color, and mixing capacity,etc based on your demands.

Here are some cases of the mud mixing hoppers what we produce for clients.>>Send an Enquiry sales@hlshiyou.com<<

Operation of jet mixing hopper

Installation

A. After the jet funnel finish mixing, the pressure loss is very large. In order to make the drilling fluid mixed by the jet funnel be able to be directly discharged into the mud tank, the funnel is usually installed on the top of the mud tanks (i.e. high-position installation), and the mixed drilling fluid is directly discharged into the mud tank without climbing.

Once the jet funnel is installed at a high position, it is necessary to design a hoist or cantilever crane to lift the drilling fluid additives to the top of the mud tank.

B. When the jet funnel is installed at a low position, a reasonable climbing angle should be designed, and the outlet should be directly connected to the mud tank to prevent the drilling fluid from overflowing from the funnel.

The jet funnel is usually directly driven by an electric centrifugal pump to mix the mud. When the mixing effect is not good, it is necessary to adjust the distance between the jet funnel nozzle and the outlet end face to achieve the best mixing effect.

Use

When working, close the butterfly valve at the bottom of the funnel. Start the centrifugal pump circulation, after the pump circulation is normal, slowly open the butterfly valve, and observe whether the jet water column is normal. If there is no overflow, then you can add drilling fluid materials from the funnel.

When adding materials, be careful not to remove the filter screen to prevent foreign objects such as packaging bags or gloves from falling into the funnel and clogging the funnel.

After the addition is completed, the centrifugal pump should circulate for a few more minutes to clean all the additives, then close the butterfly valve at the bottom of the funnel, stop the pump.

Maintenance

After each use, the solid materials inside the hopper mixing chamber and the butterfly valve seal must be rinsed clean to prevent the funnel from being blocked and the butterfly valve from being sealed tightly.

Close the butterfly valve when finishing the cleaning.