Product details

Drilling fluid solids control system is one of the most important supporting systems in oil drilling. Its main function is to remove unnecessary solid particles in the drilling fluid, maintain the stability of the drilling fluid performance, thereby ensuring the smooth operation of drilling pumps and other drilling equipment, significantly reducing costs and improving drilling efficiency.

|

Number |

Select |

Equipment |

Parameters |

Quantity |

|

1 |

Must match |

The volume is not less than 80 m3 |

1set |

|

|

2 |

Processing capacity is not less than 126m3/h |

2sets |

||

|

3 |

Sand pump capacity:180m3/h |

1set |

||

|

4 |

Optional |

Processing capacity 200㎥/h |

1set |

|

|

5 |

Processing capacity 200㎥/h |

1set |

Note: The above content is for reference only, and the actual number of packages depends on site conditions.

1. Drilling rigs with a drilling depth of less than 2000m should be equipped with drilling fluid tanks, vibrating screens and mixing and weighing devices.

2. Drilling rigs with a drilling depth of more than 2000m (including 2000m) should be equipped with drilling fluid tanks, vibrating screens, desanders, desilters and mixing and weighing devices.

3. According to the requirements of drilling technology and drilling fluid system, it can also be equipped with deaerator, centrifuge and other equipment.

4. Drilling rigs engaged in exploration wells, gas wells and oil wells with a gas-oil ratio above 300 should be equipped with degassers, centrifuges and shear pumps.

5. According to the actual drilling process requirements, special operation equipment is required, including H2S drilling, underbalanced drilling, etc.

6. Each mud tank should be equipped with corresponding mud agitator, mud gun and lighting system according to drilling process requirements.

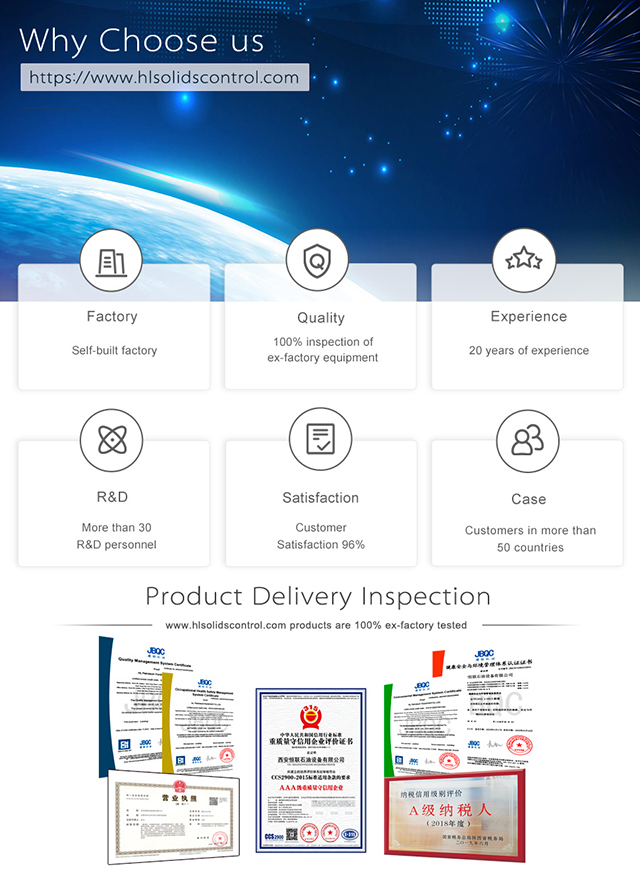

Why choose us?

HL Factory

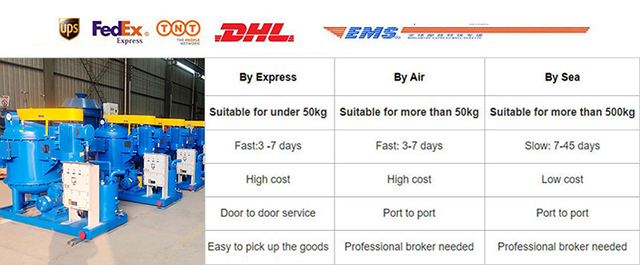

About Shipping