Product details

Centrifugal Degasser is a new type of degassing equipment, which is a special equipment for processing gas intrusion drilling fluid. Usually installed after the vibrating screen. It is suitable for the matching of various mud purification systems. It plays an important role in restoring the specific gravity of the mud, stabilizing the viscosity performance of the mud, and reducing drilling costs.

The processing capacity of the atmospheric centrifugal degasser depends on the distance from the degasser bottom to the within mud tanks liquid surface and the density of the drilling fluid. The deeper the bottom is immersed in the drilling fluid, the greater the amount of gas-invaded drilling fluid that the centrifugal degasser can handle. >>Send an Enquiry sales@hlsolidscontrol.com<<

Centrifugal Degasser Features

1. Reasonable design and special speed reducer makes it working smooth and has a constant speed.

2. Low noise and long service time.

3. Wide fluid tread range:marsh funnel 20~80s

4. Long separation blade, makes the HLCQ centrifugal degasser has a better seperation efficiency.

5. New designed mud discharge, makes it has a big handling capacity.

Centrifugal Degasser Parameters >>Send an Enquiry sales@hlsolidscontrol.com<<

|

Modle |

HLCQ240 |

HLCQ300 |

|

Capacity |

240m3/h |

300m3/h |

|

Motor power |

11kw |

18.5kw |

|

Seperation efficiency |

>= 85% |

>=85% |

|

Voltage |

380V/50HZ 3phase |

|

|

Dimension |

2750*1185*1105mm |

3570*1280*1000mm |

|

Weight |

900kg |

1100kg |

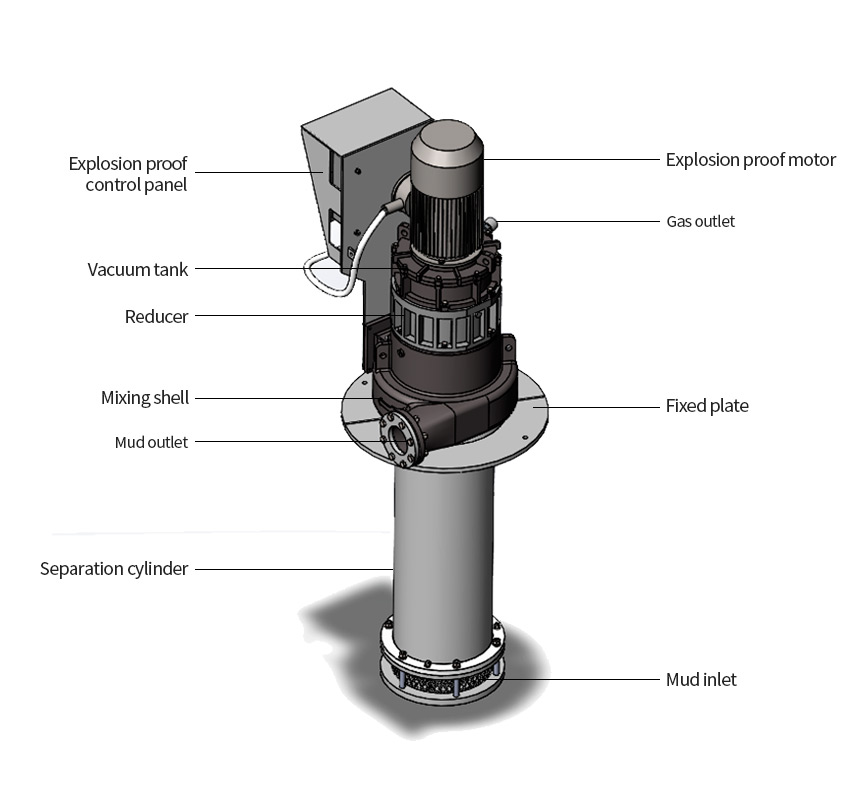

Xi'an HL centrifugal degasser is mainly composed of explosion-proof motor, electrical control assembly, vacuum pump assembly, reducer assembly and liquid-gas separation assembly. The structure design is reasonable, compact and excellent in performance. The degasser is equipped with liquid and gas separation blades, which improves the separation efficiency; adopts a new type of slurry discharge device, which greatly improves the processing capacity of the whole machine. When using a centrifugal degasser, the liquid-gas separator tube needs to be immersed in the drilling fluid. When the motor drives the main shaft to rotate, the gas-immersed drilling fluid is first sent into the separation cavity above it by the impeller at the bottom of the degasser, and the rotation of the separation blade in the separation cavity drives the drilling fluid to rotate accordingly. On the inner wall of the separation cylinder is formed a thin liquid layer of about 2 to 3 cm thick that moves upward in a spiral in a vortex state. The rotating liquid thin layer forms a centrifugal force field, so the gas and liquid phases are separated rapidly.

The bubble moves toward the axis, and the liquid is close to the inner wall of the separation cylinder. When the bubbles reach the inner surface of the thin layer of cyclonic fluid, due to the negative pressure in the separation chamber of the degasser, the bubbles can quickly break through the surface tension of the liquid to burst and be quickly drawn out by the vacuum pump. The degassed drilling fluid spirally rises along the inner wall of the separation cylinder and is discharged from the discharge port.

Xi'an HL Petroleum Equipment Co., Ltd. is a company specializing in the production and development of solids control equipment. It provides various types of products and supports customized services. If you are interested in drilling fluid degasser or other products, welcome to consult. You can contact our sales team to learn more about our product specifications, customization options, prices and more. We will wholeheartedly provide you with high-quality products and professional services. >>Send an Enquiry sales@hlsolidscontrol.com<<

Why choose us?

HL Factory

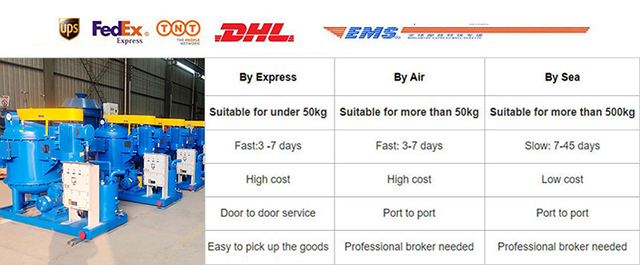

About Shipping