Linear Motion Shale Shaker

Product details

The linear motion shale shaker uses two vibrating motors of equal mass and diameter product, relying on the principle of self-synchronization to realize the linear movement of the screen box along a certain direction, so as to achieve the purpose of screening and discharging cuttings particles in the drilling fluid.

Linear Motion Shale Shaker Components

Linear Motion Shale Shaker Components1. Base assembly: Provides the basic support for the linear motion shale shaker to ensure the stable operation of the entire device.

2. Screen box assembly: The screen box is the area where the drilling fluid is placed. The solid-liquid separation in the drilling fluid is achieved through vibration, and solid particles such as cuttings are screened out of the drilling fluid.

3. Screen box inclination adjustment device assembly: used to adjust the inclination angle of the screen box to help optimize the screening effect and processing capacity.

4. Anti-splash device assembly: The anti-splash device is used to ensure that no mud splash occurs during the operation of the equipment and to ensure the safety of operators.

5. Mud box assembly: used to collect solid particles discharged from the screen box for easy processing and subsequent recycling.

6. Electrical control system assembly: responsible for controlling the start and stop, vibration frequency and other operating parameters of the linear motion shale shaker to realize automatic control.

Linear Motion Shale Shaker Parameters

Linear Motion Shale Shaker Parameters

| Model |

HZS703 |

HZS803 |

HZS604 |

HZS605 |

| Vibration Motion |

Linear |

Linear |

Linear |

Linear |

| Capacity |

30L/S |

35L/S |

40L/S |

45L/S |

| Screen Area |

2.2㎡ |

2.7㎡ |

2.7㎡ |

3.4㎡ |

| Screen Specifications |

3×1050×700mm |

3×1080×830mm |

4×1165×585mm |

5×1165×585mm |

| Motor Power |

2×1.5kW |

2×1.8kW |

2×2.2kW |

2×2.5kW |

| Deck Angle Range |

-1°~3° |

-1°~3° |

-1°~3° |

-1°~3° |

| Dimensions |

2850×1590×1550 |

3150×1800×1630 |

2650×1700×1750 |

2850×1750×1650 |

| Weight |

1680kg |

1800kg |

1950kg |

2350kg |

The processing capacity of linear motion

shale shaker is a key parameter, which is used to indicate the amount of material passing through the screen surface per unit time, usually measured in tons/hour. The actual processing capacity is affected by many factors, including the selection of motion parameters of the linear motion shale shaker itself, and factors such as drilling fluid type, density, viscosity, size and content of solid particles, and hole network size. The motion parameter of the linear motion shale shaker is one of the key factors affecting the processing power. These parameters include vibration frequency, vibration amplitude and inclination angle, etc. By choosing these parameters reasonably, the screening effect can be optimized and the processing capacity can be improved, so as to achieve higher production efficiency and operation effect.

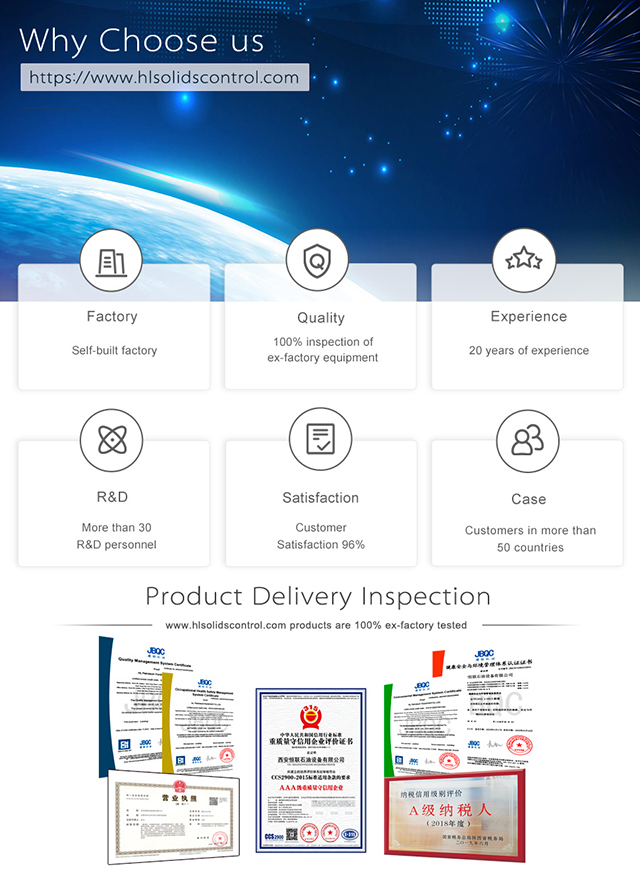

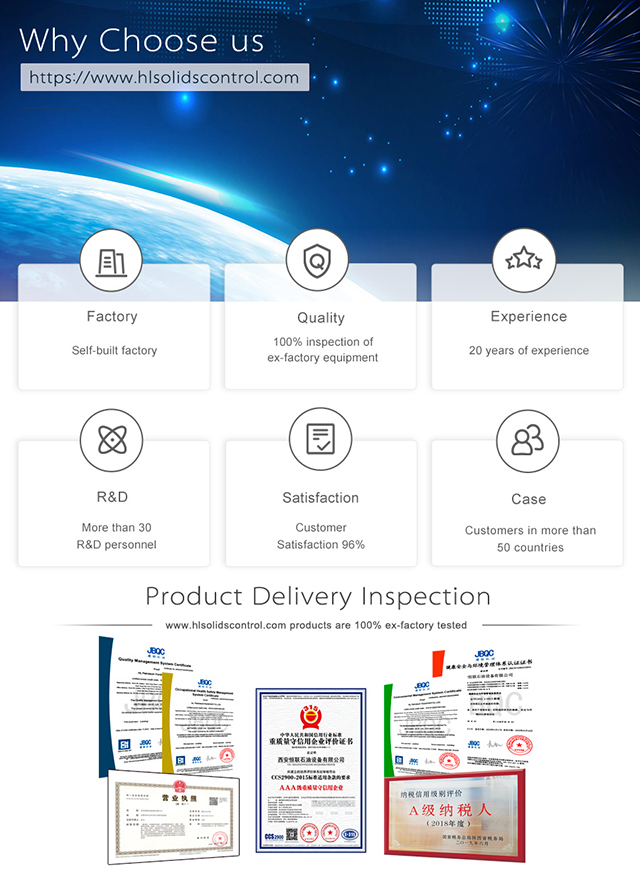

HL Petroleum is a professional solids control equipment manufacturer.We have more than 20 years of research, design and manufacturing experience.HL Petroleum

solids control equipment has long service life and high cost performance. It is a trustworthy brand in the industry!

Why choose us?

HL Factory

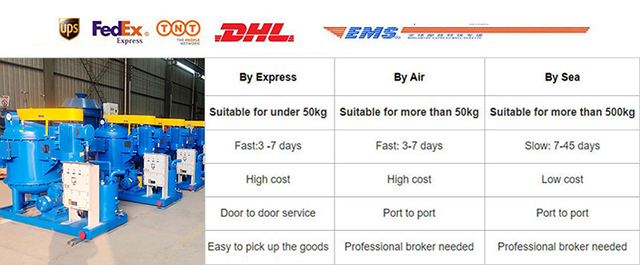

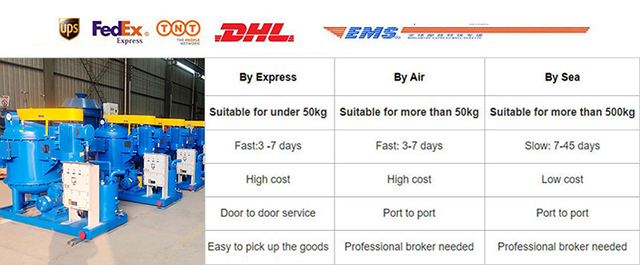

About Shipping