Solids Control Equipment

- Mud Shale Shaker

- Degasser

- Mud Cleaner

- Centrifuge

- Mud Agitator

- Mud Gun

- Jet Mud Mixer

- Centrifugal Pump

- Shear Pump

- Spray Pump

- Vacuum Pump

- Mud Gas Separator

- Ignition

- Drilling Cuttings Dryer

- Filter Press

- Conveyor

Mud Treatment System

- Drilling Fluid Solids Control System

- Water-based Mud Treatment System

- Oil based Mud Treatment System

- Trenchless Mud Treatment System

- Mud Mixing System

- Drilling Fluid Cooling System

- Truck mounted Mud Circulation System

- Barite Recovery System

Tank and Steel Structure

- Rig Mat

- Elevated Diesel Tank

- Nested Water Tank

- Fracturing Fluid Tank

- Drilling Pipe Basket

- Drill Cuttings Box

- Mud Storage Tank

Drilling Tools and Spare Parts

Phone: 86-29-88680837

Mail: sales@hlsolidscontrol.com

Add: Room 804, Building 1, Western Cloud Valley Phase II, Fengxi New Town, Xixian New District, Shaanxi Province

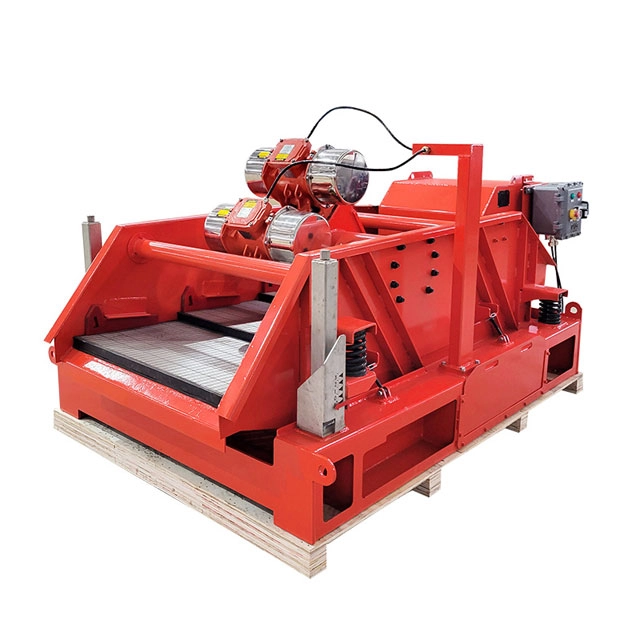

Mud Shale Shaker FLC2000

Product Overview:

The linear motion mud shale shaker is a first-stage equipment for solid-liquid separation of drilling fluid, and it is suitable for the drilling fluid return control system of oil and gas drilling.

Mud Shale Shaker FLC2000 Details

Overview of linear motion shale shaker

Drilling fluid shale shaker FLC2000 is a first-stage equipment for solid-liquid separation of drilling fluid. It is suitable for the drilling fluid solid control system of oil and gas drilling. Linear movement along a certain direction achieves the purpose of screening and discharging cuttings particles in drilling fluid. >>Send an Enquiry sales@hlsolidscontrol.com<<

1. High efficiency of linear vibration trajectory.

2. Any combination of double, triple and quadruple.

3. The angle of the screen box can be adjusted to prevent the slurry from running out.

4. Hook edge plate screen, economical and affordable.

5. Screen box inclination adjustment device to prevent pulp running.

Technical parameters of linear motion shale shaker >>Send an Enquiry sales@hlsolidscontrol.com<<

|

Model |

HZS703 |

HZS803 |

HZS604 |

HZS605 |

|

Vibration Mode |

Linear Motion |

Linear Motion |

Linear Motion |

Linear Motion |

|

Capacity |

30L/S |

35L/S |

40L/S |

45L/S |

|

Screen Area |

2.2㎡ |

2.7㎡ |

2.7㎡ |

3.4㎡ |

|

Screen Qty & Size |

3×1050×700mm |

3×1080×830mm |

4×1165×585mm |

5×1165×585mm |

|

Motor Power |

2×1.5kW |

2×1.8kW |

2×2.2kW |

2×2.5kW |

|

Deck Angle Range |

-1°~3° |

-1°~3° |

-1°~3° |

-1°~3° |

|

Dimension: L×W×H |

2850×1590×1550 |

3150×1800×1630 |

2650×1700×1750 |

2850×1750×1650mm |

|

Weight |

1680kg |

1800kg |

1950kg |

2350kg |

What are the commonly used mesh sizes of shale shaker in drilling?

The commonly used mesh sizes (the number of holes per inch) are 12 mesh, 16 mesh, 20 mesh, 40 mesh, 60 mesh and 80 mesh, and the densest mesh used on site is 200 mesh. The mesh size of the shale shaker used in drilling rig can be reasonably selected according to the on-site drilling needs, and the screen should be tightened and replaced in time.

HL Petroleum is a professional drilling fluid shale shaker suppliers.