Solids Control Equipment

- Mud Shale Shaker

- Degasser

- Mud Cleaner

- Centrifuge

- Mud Agitator

- Mud Gun

- Jet Mud Mixer

- Centrifugal Pump

- Shear Pump

- Spray Pump

- Vacuum Pump

- Mud Gas Separator

- Ignition

- Drilling Cuttings Dryer

- Filter Press

- Conveyor

Mud Treatment System

- Drilling Fluid Solids Control System

- Water-based Mud Treatment System

- Oil based Mud Treatment System

- Trenchless Mud Treatment System

- Mud Mixing System

- Drilling Fluid Cooling System

- Truck mounted Mud Circulation System

- Barite Recovery System

Tank and Steel Structure

- Rig Mat

- Elevated Diesel Tank

- Nested Water Tank

- Fracturing Fluid Tank

- Drilling Pipe Basket

- Drill Cuttings Box

- Mud Storage Tank

Drilling Tools and Spare Parts

Phone: 86-29-88680837

Mail: sales@hlsolidscontrol.com

Add: Room 804, Building 1, Western Cloud Valley Phase II, Fengxi New Town, Xixian New District, Shaanxi Province

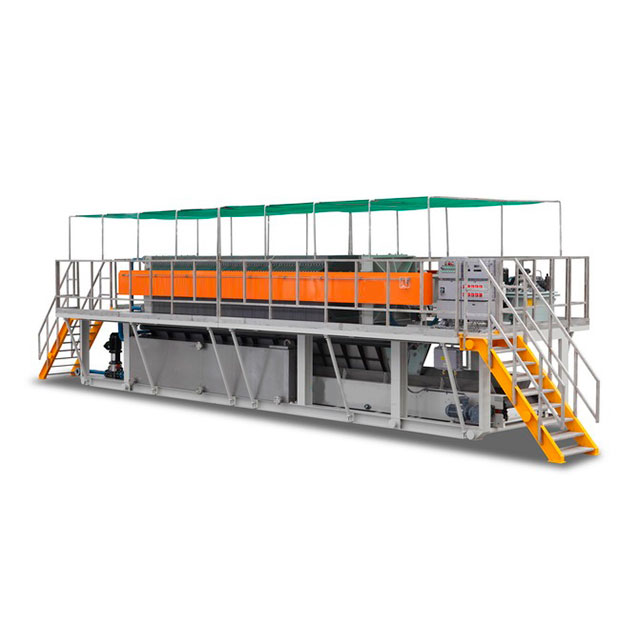

Automatic Diaphragm Filter Press

Product Overview:

The automatic diaphragm filter press is composed of a diaphragm plate and a chamber filter plate arranged to form a filter chamber. The slurry is input into the filter chamber under the pressure of the feed pump, and the solid and liquid in the slurry are separated through the filter medium (filter cloth). When the solids form the filter cake, pass high-pressure air to the diaphragm plate to fully squeeze the solids in the filter chamber to reduce the moisture content of the filter cake. For users who require high filtration and moisture content of viscous materials, this machine has its unique characteristics

Automatic Diaphragm Filter Press Details

The automatic diaphragm filter press is composed of a diaphragm plate and a chamber filter plate arranged to form a filter chamber. The slurry is input into the filter chamber under the pressure of the feed pump, and the solid and liquid in the slurry are separated through the filter medium (filter cloth). When the solids form the filter cake, pass high-pressure air to the diaphragm plate to fully squeeze the solids in the filter chamber to reduce the moisture content of the filter cake. For users who require high filtration and moisture content of viscous materials, this machine has its unique characteristics.