Mud Treatment System

- Drilling Fluid Solids Control System

- Water-based Mud Treatment System

- Oil based Mud Treatment System

- Trenchless Mud Treatment System

- Mud Mixing System

- Drilling Fluid Cooling System

- Truck mounted Mud Circulation System

- Barite Recovery System

Solids Control Equipment

- Mud Shale Shaker

- Degasser

- Mud Cleaner

- Centrifuge

- Mud Agitator

- Mud Gun

- Jet Mud Mixer

- Centrifugal Pump

- Shear Pump

- Spray Pump

- Vacuum Pump

- Mud Gas Separator

- Ignition

- Drilling Cuttings Dryer

- Filter Press

- Conveyor

Drilling Tools and Spare Parts

- Mud Shale Shaker Spare Parts

- Centrifugal Pump Spare Parts

- Mud Pump Spare Parts

- Centrifuge Spare Parts

- Mud Tank Bottom Valve

- Mud Hopper

- Mud Tank Level Alarm

- Polyurethane Cyclone

- Electric Motor

- WPS Reducer

- Mud Tank Union

- Explosion-proof Water Tank Heater

Tank and Steel Structure

WeChat: 86-13735815206 / 86-17392256505

Phone: 86-29-88680837

Mail: sales@hlsolidscontrol.com

Add: Room 804, Building 1, Western Cloud Valley Phase II, Fengxi New Town, Xixian New District, Shaanxi Province

Phone: 86-29-88680837

Mail: sales@hlsolidscontrol.com

Add: Room 804, Building 1, Western Cloud Valley Phase II, Fengxi New Town, Xixian New District, Shaanxi Province

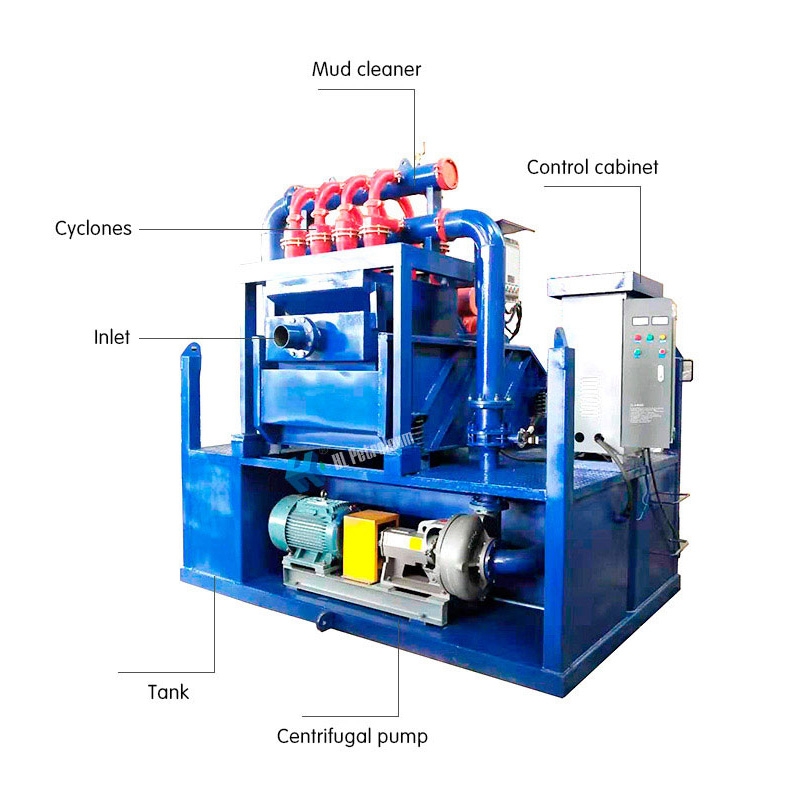

Mud Cleaning System

Product Overview:

HMC mud cleaning system is widely used in many fields such as trenchless mud recovery, shield mud water balance, river channel mud cleaning and geothermal well mud cleaning, etc.

Mud Cleaning System Details

HMC mud cleaning system is widely used in many fields such as trenchless mud recovery, shield mud water balance, river channel mud cleaning and geothermal well mud cleaning, etc.

1. HL double deck linear motion shale shaker

a. High-power vibration motor improves work efficiency by 20%

b. 10 polyurethane desilting cyclones, which can separate solid particles assmall as 0.0025mm

c. Polyurethane slot screen, the screen life is extended by 30%

d. The mud flowing out of the bottom of the desilter passes through theultra-fine screen after secondary filtration

2. Electrical control box 380V/50HZ

3. Skid cans

a. Walkways, guardrails and stairsensure safe construction

b. Skid-mounted base, easy to move

3. Desilting pumpSB 5*6-11 Mechanical Seal

Mud Cleaning System Parameter

Mud Cleaning System Features

1. Sufficient purification of mud: Through the treatment of mud cleaning equipment, solid particles and impurities in mud can be effectively removed, so as to control the performance index of mud, reduce the occurrence of stuck pipe accidents, and improve the quality and stability of drilling.

2. Effective separation of soil muck: The mud cleaning device in the system can separate the muck from the mud, thereby improving the efficiency and speed of construction and making the drilling work smoother.

3. Reuse of mud: After purification, the mud can be recycled and reused, which avoids a lot of waste of mud, saves the use of mud making materials, and thus reduces construction costs.

4. Closed-circuit circulation of mud and low water content of dregs: The mud cleaning system adopts a closed-circuit circulation, which makes the mud circulate in the system, reduces the discharge of mud, and is beneficial to reduce environmental pollution. At the same time, the lower moisture content of slag also helps to reduce the adverse impact on the environment.

1. HL double deck linear motion shale shaker

a. High-power vibration motor improves work efficiency by 20%

b. 10 polyurethane desilting cyclones, which can separate solid particles assmall as 0.0025mm

c. Polyurethane slot screen, the screen life is extended by 30%

d. The mud flowing out of the bottom of the desilter passes through theultra-fine screen after secondary filtration

2. Electrical control box 380V/50HZ

3. Skid cans

a. Walkways, guardrails and stairsensure safe construction

b. Skid-mounted base, easy to move

3. Desilting pumpSB 5*6-11 Mechanical Seal

Mud Cleaning System Parameter

| Capatity(m3/h) | Separation size(µm) | Slag sareming capaely(t/h) | Motor power(kw) | Dimensions(mm) | Weight(kg) |

| HMC20 | 16 | ≤10 | 4 | 1500×800×1100 | 700 |

| HMC40 | 20 | 10~20 | 7.7 | 1800×1100×1350 | 1500 |

| HMC60 | 20 | 20~30 | 13.6 | 2750×1850×2200 | 2700 |

| HMC80 | 20 | 25~40 | 18 | 3000×2100×2750 | 3500 |

| HMC100 | 25 | 30~50 | 25 | 3300×2100×2750 | 3850 |

| HMC120 | 30 | 30~60 | 33.6 | 3550×2250×2830 | 4500 |

| HMC160 | 35 | 40~60 | 41 | 3550×2250×2850 | 4800 |

| HMC200 | 40 | 50~70 | 50 | 3750×2350×2850 | 5100 |

Mud Cleaning System Features

1. Sufficient purification of mud: Through the treatment of mud cleaning equipment, solid particles and impurities in mud can be effectively removed, so as to control the performance index of mud, reduce the occurrence of stuck pipe accidents, and improve the quality and stability of drilling.

2. Effective separation of soil muck: The mud cleaning device in the system can separate the muck from the mud, thereby improving the efficiency and speed of construction and making the drilling work smoother.

3. Reuse of mud: After purification, the mud can be recycled and reused, which avoids a lot of waste of mud, saves the use of mud making materials, and thus reduces construction costs.

4. Closed-circuit circulation of mud and low water content of dregs: The mud cleaning system adopts a closed-circuit circulation, which makes the mud circulate in the system, reduces the discharge of mud, and is beneficial to reduce environmental pollution. At the same time, the lower moisture content of slag also helps to reduce the adverse impact on the environment.