WhatsApp: 86-13735815206 / 86-17392256505

WeChat: 86-13735815206 / 86-17392256505

Phone: 86-29-88680837

Mail: sales@hlsolidscontrol.com

Add: Room 804, Building 1, Western Cloud Valley Phase II, Fengxi New Town, Xixian New District, Shaanxi Province

WeChat: 86-13735815206 / 86-17392256505

Phone: 86-29-88680837

Mail: sales@hlsolidscontrol.com

Add: Room 804, Building 1, Western Cloud Valley Phase II, Fengxi New Town, Xixian New District, Shaanxi Province

HL HYQ Drilling Mud Liquid-Gas Separator Product Features

Time: 2024-06-13 Source: Solids Control Equipment Author: Mrek

Drilling fluid liquid-gas separator, also known as mud gas separator, is a special equipment for primary degassing of gas-invaded drilling fluid. It is mainly used to remove large bubbles with a diameter of about φ3 to φ25mm in gas-invaded drilling fluid. These large bubbles belong to the expansive gas in the drilling fluid, which seriously endangers drilling safety.

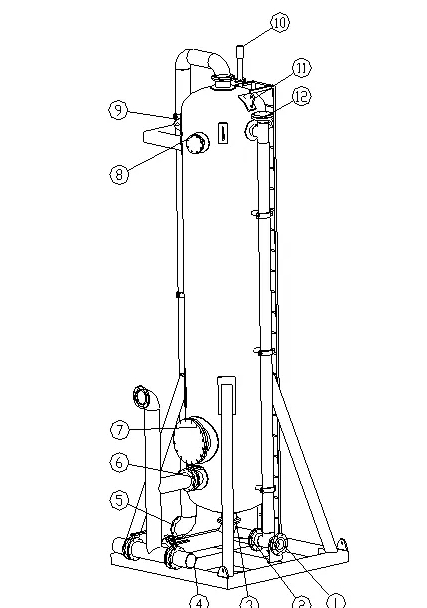

1. Liquid inlet 2. Buffer baffle 3. Drain port 4. Drain pipe 5. Exhaust port 6. Drain port 7. Manhole 8. Cleaning port 9. Tensioning ear plate 10. Safety valve 11. Lifting ear 12. Buffer baffle

Working principle of liquid-gas separator

The gas-invaded drilling fluid enters the liquid-gas separator through the liquid inlet, passes through the diverter first, and then sprays out through the slurry inlet pipe. It collides, scatters and flows downward on the inner baffle, generating turbulence. Under the action of gravity, the gas and liquid are separated, and the separated gas is discharged through the gas outlet at the top of the tank body. The degassed drilling fluid flows into the circulation tank through the vibrating screen.

It is a special equipment for primary degassing of gas-invaded drilling fluid. It is mainly used to remove large bubbles with a diameter of about ≥φ3mm in gas-invaded drilling fluid. These large bubbles refer to most of the expanded gas in a certain part of the wellbore annulus in the drilling fluid. If not removed, it is easy to cause blowouts and even blow up the surface of the drilling platform. The HYQ series mud liquefaction gas separator is made of high-quality materials, which can effectively prevent the erosion of harmful gases and ensure the safe production of man and machine.

The HL HYQ series drilling mud liquid-gas separator is made of high-quality materials, which can effectively prevent H2S corrosion, effectively prevent well kicks, and ensure construction safety and personnel safety.

HL HYQ series solid control equipment liquid-gas separator design features:

1. Scientific and reasonable structure, small space occupation, and standardized shape;

2. The bottom drainage liquid level control is adopted to effectively solve the problem of sand accumulation in the tank;

3. The unique gas separation channel design improves the gas removal efficiency;

4. The physical impact separation is adopted, and the gas separation effect is continuous and stable;

HL Solid Control is a professional manufacturer of solid control equipment and systems integrating scientific and technological innovation research and development, production and manufacturing, global marketing, technical services, and technical consulting. In addition to producing liquid-gas separators, the company also produces vibrating screens, centrifugal pumps, sand and mud removal cleaners, drill cuttings dryers, mud recovery systems and other solid control equipment, shield mud purification systems, river dredging systems and other purification systems. Welcome customers to come for consultation and inspection, we will serve you wholeheartedly.

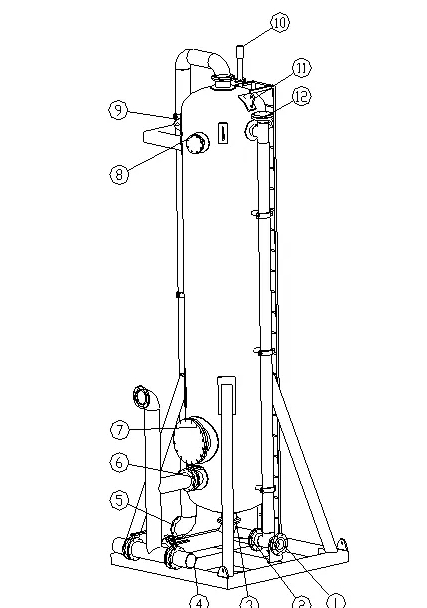

1. Liquid inlet 2. Buffer baffle 3. Drain port 4. Drain pipe 5. Exhaust port 6. Drain port 7. Manhole 8. Cleaning port 9. Tensioning ear plate 10. Safety valve 11. Lifting ear 12. Buffer baffle

Working principle of liquid-gas separator

The gas-invaded drilling fluid enters the liquid-gas separator through the liquid inlet, passes through the diverter first, and then sprays out through the slurry inlet pipe. It collides, scatters and flows downward on the inner baffle, generating turbulence. Under the action of gravity, the gas and liquid are separated, and the separated gas is discharged through the gas outlet at the top of the tank body. The degassed drilling fluid flows into the circulation tank through the vibrating screen.

It is a special equipment for primary degassing of gas-invaded drilling fluid. It is mainly used to remove large bubbles with a diameter of about ≥φ3mm in gas-invaded drilling fluid. These large bubbles refer to most of the expanded gas in a certain part of the wellbore annulus in the drilling fluid. If not removed, it is easy to cause blowouts and even blow up the surface of the drilling platform. The HYQ series mud liquefaction gas separator is made of high-quality materials, which can effectively prevent the erosion of harmful gases and ensure the safe production of man and machine.

The HL HYQ series drilling mud liquid-gas separator is made of high-quality materials, which can effectively prevent H2S corrosion, effectively prevent well kicks, and ensure construction safety and personnel safety.

HL HYQ series solid control equipment liquid-gas separator design features:

1. Scientific and reasonable structure, small space occupation, and standardized shape;

2. The bottom drainage liquid level control is adopted to effectively solve the problem of sand accumulation in the tank;

3. The unique gas separation channel design improves the gas removal efficiency;

4. The physical impact separation is adopted, and the gas separation effect is continuous and stable;

HL Solid Control is a professional manufacturer of solid control equipment and systems integrating scientific and technological innovation research and development, production and manufacturing, global marketing, technical services, and technical consulting. In addition to producing liquid-gas separators, the company also produces vibrating screens, centrifugal pumps, sand and mud removal cleaners, drill cuttings dryers, mud recovery systems and other solid control equipment, shield mud purification systems, river dredging systems and other purification systems. Welcome customers to come for consultation and inspection, we will serve you wholeheartedly.