WhatsApp: 86-13735815206 / 86-17392256505

WeChat: 86-13735815206 / 86-17392256505

Phone: 86-29-88680837

Mail: sales@hlsolidscontrol.com

Add: Room 804, Building 1, Western Cloud Valley Phase II, Fengxi New Town, Xixian New District, Shaanxi Province

WeChat: 86-13735815206 / 86-17392256505

Phone: 86-29-88680837

Mail: sales@hlsolidscontrol.com

Add: Room 804, Building 1, Western Cloud Valley Phase II, Fengxi New Town, Xixian New District, Shaanxi Province

Introduction to filter press | HL Solids control

Time: 2024-05-06 Source: Author:

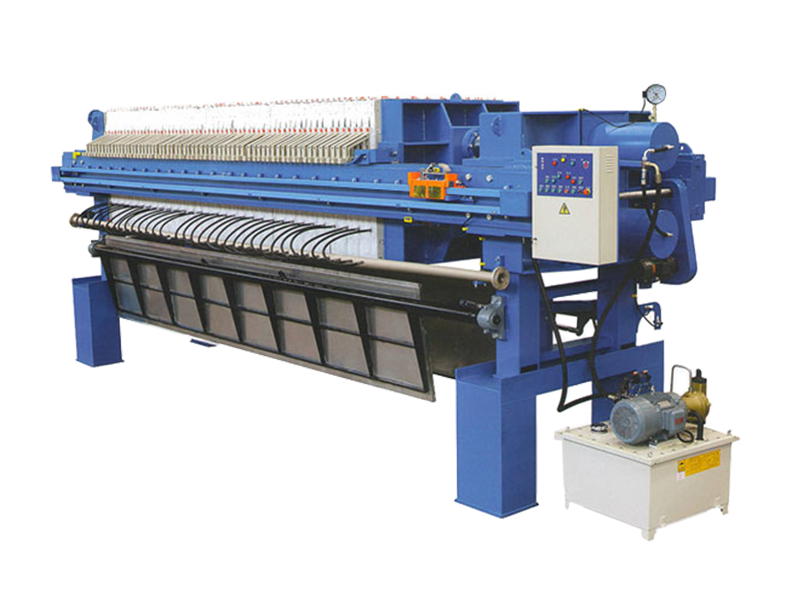

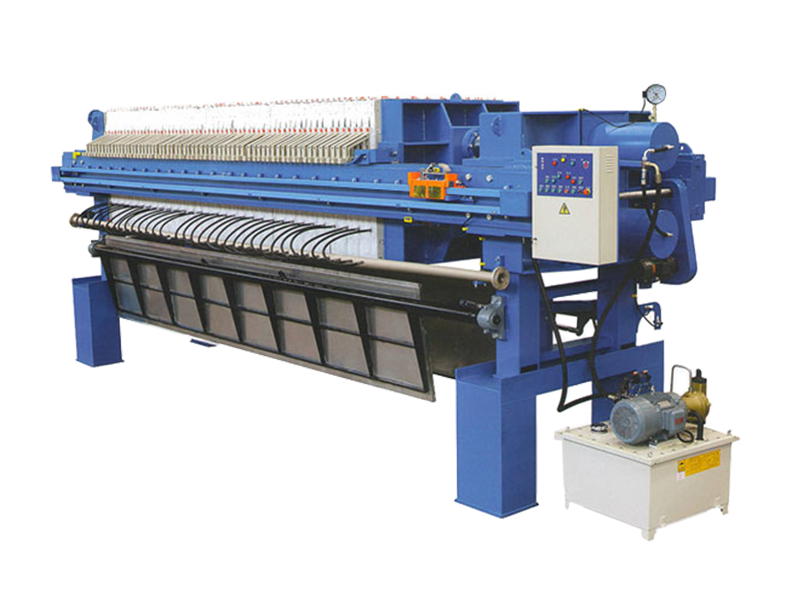

The filter press is a solid-liquid separation equipment that is widely used in sludge dewatering projects and is one of the common solids control equipment. In the early 18th century, filter presses were used in chemical production. Currently, filter presses are still widely used in oil drilling, mining, chemicals, pharmaceuticals, metallurgy, dyes, food, brewing, ceramics and environmental protection industries.

Working principle of filter press

The basic principle of the filter press is: the mixed liquid flows through the filter medium (filter cloth), the solids stay on the filter cloth, and gradually accumulate on the filter cloth to form a filter cake. The filtrate flows out of the filter plate through the corner opening and enters the manifold, producing solid-free filtrate, thereby achieving solid-liquid separation processing. Depending on the needs, the diameter of the solid particles that can be filtered by the filter press is also different. The specially designed filter cloth can intercept particles with a particle size less than 1 μm.

As the filtration process proceeds, filter cake filtration begins, the thickness of the mud cake gradually increases, and the filtration resistance increases. The longer the filtration time, the higher the separation efficiency. In addition to the excellent separation effect and high solid content of the mud cake, the filter press can also provide a further separation process: during the filtration process, the filter mud cake can be effectively washed at the same time, so that valuable substances can be recovered And high purity filter mud cake can be obtained.

Filter press composition

The filter press is mainly composed of a transmission part, a filter plate part, a pressing plate part, a thrust plate part, a pressing device (mainly a hydraulic pressing device), a hydraulic system, an electronic control system, and auxiliary parts.

Three operating modes of filter press

Semi-automatic mode: Press the start button, and the cycle from closing the filter chamber to opening it will be automatic. To proceed with the next cycle, you need to press the start button again.

Automatic mode: Press the start button and the filter press will work cycle after cycle until the stop button is pressed.

Manual mode: When used for maintenance equipment, the filter press can run or stop at any point in the cycle.

Filter press working process

1. Press the filter plate tightly. Operate the hydraulic system to move the tail plate toward the head plate and tighten all filter plates between the head plate and the tail plate. As a result, a hollow sealed filter chamber is formed between adjacent filter plates.

2. Press filtration process. The feed pump transports the mud from the feed hole of the tail plate to the filter chamber. When the filter chamber is filled with mud, the filter press process begins, and the mud is separated from solid and liquid with the help of the pressure of the feed pump. In the early stage of filter press, the thickness of the mud cake in the filter chamber is not large, the resistance of the filter cake is small, and the dehydration speed is fast. Usually, a low-lift, large-flow pump is used at this time. As the thickness of the filter cake increases and the resistance increases, the filter press speed decreases. At this time, a pump with high lift and small flow rate should be used. The time required for the filter press process is determined according to the filtration characteristics and process requirements of the mud. When the specified filter press time is reached, the feeding is stopped and the filter press process is completed.

3. Loosen the filter plate. Operate the hydraulic system to return the head plate to its original position.

4. Unload the filter plate. The transmission chain on the transmission and opening device successively pulls the filter plates apart, and the filter cake falls off by its own weight and is transported away by the lower conveyor.

HL Petroleum is a professional solids control equipment manufacturer.The main products include Shale Shakers, Mud Cleaner, Vacuum Degasser, Desander, Desilter, Centrifugal Pump, Decanting Centrifuge,mud agitators, poor boy degasser, Mud Gun,Mud Pumps,mud tank etc. These products are widely used in oil drilling, solid-liquid separation, mud purification and other fields.

HL Solids control specializes in the production of plate and frame filter presses, chamber filter presses, automatic diaphragm filter presses, mud filter presses, we have strong production strength and rich industry experience.HL Solids Control products are professional, reliable, cost-effective and customizable.welcome to consult!

Working principle of filter press

The basic principle of the filter press is: the mixed liquid flows through the filter medium (filter cloth), the solids stay on the filter cloth, and gradually accumulate on the filter cloth to form a filter cake. The filtrate flows out of the filter plate through the corner opening and enters the manifold, producing solid-free filtrate, thereby achieving solid-liquid separation processing. Depending on the needs, the diameter of the solid particles that can be filtered by the filter press is also different. The specially designed filter cloth can intercept particles with a particle size less than 1 μm.

As the filtration process proceeds, filter cake filtration begins, the thickness of the mud cake gradually increases, and the filtration resistance increases. The longer the filtration time, the higher the separation efficiency. In addition to the excellent separation effect and high solid content of the mud cake, the filter press can also provide a further separation process: during the filtration process, the filter mud cake can be effectively washed at the same time, so that valuable substances can be recovered And high purity filter mud cake can be obtained.

Filter press composition

The filter press is mainly composed of a transmission part, a filter plate part, a pressing plate part, a thrust plate part, a pressing device (mainly a hydraulic pressing device), a hydraulic system, an electronic control system, and auxiliary parts.

Three operating modes of filter press

Semi-automatic mode: Press the start button, and the cycle from closing the filter chamber to opening it will be automatic. To proceed with the next cycle, you need to press the start button again.

Automatic mode: Press the start button and the filter press will work cycle after cycle until the stop button is pressed.

Manual mode: When used for maintenance equipment, the filter press can run or stop at any point in the cycle.

Filter press working process

1. Press the filter plate tightly. Operate the hydraulic system to move the tail plate toward the head plate and tighten all filter plates between the head plate and the tail plate. As a result, a hollow sealed filter chamber is formed between adjacent filter plates.

2. Press filtration process. The feed pump transports the mud from the feed hole of the tail plate to the filter chamber. When the filter chamber is filled with mud, the filter press process begins, and the mud is separated from solid and liquid with the help of the pressure of the feed pump. In the early stage of filter press, the thickness of the mud cake in the filter chamber is not large, the resistance of the filter cake is small, and the dehydration speed is fast. Usually, a low-lift, large-flow pump is used at this time. As the thickness of the filter cake increases and the resistance increases, the filter press speed decreases. At this time, a pump with high lift and small flow rate should be used. The time required for the filter press process is determined according to the filtration characteristics and process requirements of the mud. When the specified filter press time is reached, the feeding is stopped and the filter press process is completed.

3. Loosen the filter plate. Operate the hydraulic system to return the head plate to its original position.

4. Unload the filter plate. The transmission chain on the transmission and opening device successively pulls the filter plates apart, and the filter cake falls off by its own weight and is transported away by the lower conveyor.

HL Petroleum is a professional solids control equipment manufacturer.The main products include Shale Shakers, Mud Cleaner, Vacuum Degasser, Desander, Desilter, Centrifugal Pump, Decanting Centrifuge,mud agitators, poor boy degasser, Mud Gun,Mud Pumps,mud tank etc. These products are widely used in oil drilling, solid-liquid separation, mud purification and other fields.

HL Solids control specializes in the production of plate and frame filter presses, chamber filter presses, automatic diaphragm filter presses, mud filter presses, we have strong production strength and rich industry experience.HL Solids Control products are professional, reliable, cost-effective and customizable.welcome to consult!