Solids Control Equipment

- Mud Shale Shaker

- Degasser

- Mud Cleaner

- Centrifuge

- Mud Agitator

- Mud Gun

- Jet Mud Mixer

- Centrifugal Pump

- Shear Pump

- Spray Pump

- Vacuum Pump

- Mud Gas Separator

- Ignition

- Drilling Cuttings Dryer

- Filter Press

- Conveyor

Mud Treatment System

- Drilling Fluid Solids Control System

- Water-based Mud Treatment System

- Oil based Mud Treatment System

- Trenchless Mud Treatment System

- Mud Mixing System

- Drilling Fluid Cooling System

- Truck mounted Mud Circulation System

- Barite Recovery System

Tank and Steel Structure

- Rig Mat

- Elevated Diesel Tank

- Nested Water Tank

- Fracturing Fluid Tank

- Drilling Pipe Basket

- Drill Cuttings Box

- Mud Storage Tank

Drilling Tools and Spare Parts

Phone: 86-29-88680837

Mail: sales@hlsolidscontrol.com

Add: Room 804, Building 1, Western Cloud Valley Phase II, Fengxi New Town, Xixian New District, Shaanxi Province

WPS worm gearbox reducer

Product Overview:

WPS worm gearbox reducer is mainly used for agitator.

WPS worm gearbox reducer Details

The WPS worm gearbox reducer is mainly used for mud agitator and is one of the accessories of mud agitator.

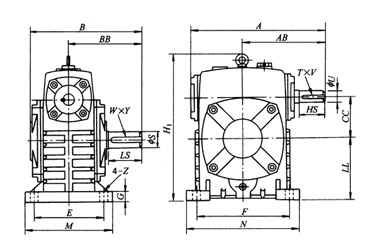

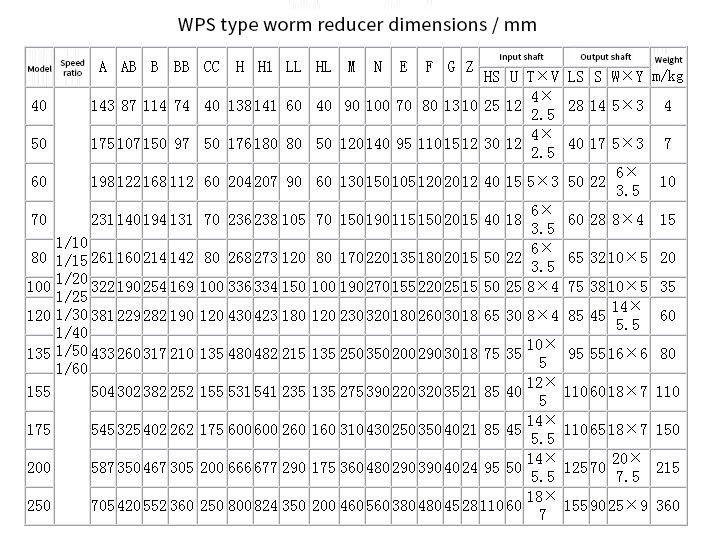

WPS Reducer Structure diagram

Reducer Features

1. A large transmission ratio can be obtained, which is more compact than a cross-axis helical gear mechanism.

2. The meshing tooth surfaces of the two wheels are in line contact, and its carrying capacity is much higher than that of the cross-axis helical gear mechanism.

3. Worm drive is equivalent to spiral drive, which is multi-tooth meshing transmission, so the transmission is stable and the noise is small

4. Has self-locking function. When the lead angle of the worm is less than the equivalent friction angle between the meshing gear teeth, the mechanism is self-locking and can realize reverse self-locking, that is, the worm can only be driven by the worm, but not by the worm. For example, the self-locking worm mechanism used in hoisting machinery, its reverse self-locking property can play a safety protection role.

5. The transmission efficiency is low and the wear is serious. When the worm gear is engaged in transmission, the relative sliding speed between the meshing gear teeth is large, so the friction loss is large and the efficiency is low. On the other hand, the relative sliding speed means that the tooth surface wears severely and generates heat. In order to dissipate heat and reduce wear, more expensive materials with better anti-friction and anti-wear properties and good lubricating devices are often used, so the cost is higher.

6. The axial force of the worm is large.

Reducer Application

WP worm gear reducer is a kind of reducer used more in the machinery industry. At present, the product has been widely used in packaging machinery, woodworking machinery, petrochemicals, bio-pharmaceuticals, construction engineering, iron and steel metallurgy, mining machinery, production lines, food machinery, mining machinery, iron and steel metallurgy, port equipment, new energy and other fields. This series of products adopts a new type of sealing device, which has good protection performance and strong adaptability to the environment. It can work continuously in harsh environments such as corrosion and humidity. It has strong versatility, convenient use and maintenance, and low maintenance cost. Especially for the production line, only a few internal transmission parts are needed to ensure the maintenance of the normal production of the whole line. Low energy consumption, superior performance, reducer efficiency up to 96%, low vibration and low noise. This series of geared motors can match various motors such as ordinary Y series, Y2 series, hoisting motors, riot motors, brake motors, frequency conversion motors, DC motors, outdoor special motors, etc.