Solids Control Equipment

- Mud Shale Shaker

- Degasser

- Mud Cleaner

- Centrifuge

- Mud Agitator

- Mud Gun

- Jet Mud Mixer

- Centrifugal Pump

- Shear Pump

- Spray Pump

- Vacuum Pump

- Mud Gas Separator

- Ignition

- Drilling Cuttings Dryer

- Filter Press

- Conveyor

Mud Treatment System

- Drilling Fluid Solids Control System

- Water-based Mud Treatment System

- Oil based Mud Treatment System

- Trenchless Mud Treatment System

- Mud Mixing System

- Drilling Fluid Cooling System

- Truck mounted Mud Circulation System

- Barite Recovery System

Tank and Steel Structure

- Rig Mat

- Elevated Diesel Tank

- Nested Water Tank

- Fracturing Fluid Tank

- Drilling Pipe Basket

- Drill Cuttings Box

- Mud Storage Tank

Drilling Tools and Spare Parts

Phone: 86-29-88680837

Mail: sales@hlsolidscontrol.com

Add: Room 804, Building 1, Western Cloud Valley Phase II, Fengxi New Town, Xixian New District, Shaanxi Province

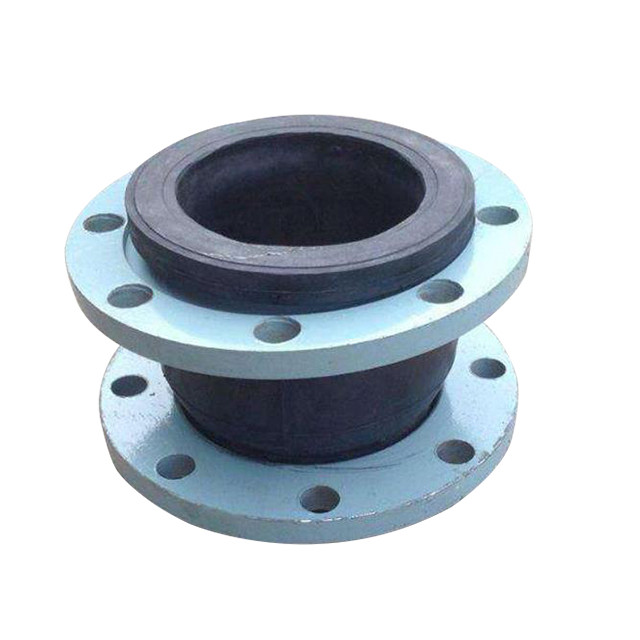

Mud Tank Hammer Union

Product Overview:

Mud tank hammer union recommended for cementing, fracturing, acidizing, testing and jam and well pressure pipeline connection can also be used for production, drilling and workover manifold andpipeline connection, also can be connected to other systems for steam system.

Mantissa is 2 union general working temperature 29 ℃ ~80 C

As for acid gases such as H2S, the user should be stated in advance, to select a proper seal form and a rubber pad.

Mud Tank Hammer Union Details

Mud tank hammer union application and working environment

Recommended for cementing, fracturing, acidizing, testing and jam and well pressure pipeline connection can also be used for production, drilling and workover manifold andpipeline connection, also can be connected to other systems for steam system.

Mantissa is 2 union general working temperature 29 ℃ ~80 C

As for acid gases such as H2S, the user should be stated in advance, to select a proper seal form and a rubber pad.

Mud Tank Hammer Union Connection method

2.1 union male head is connected with the female head

Put the sealing ring in the female head and hit the three claws of the compression nut with a hammer (clockwise to tighten, counterclockwise to loosen)

2.2 Welding connection of union male and female heads and hoses

The welding method is generally butt welding, and the electrode material should be similar to the Union base metal during welding.

Align the axis of the union male and female head with the axis of the component to be connected. In case of heat-resistant parts, cool down or remove the heat-resistant parts in advance to avoid damage to the pipeline or sealing ring due to heat conduction due to welding. Wait for heat-resistant parts. After welding, air cooling should be used to reduce the stress of the welding part to avoid welding defects such as cracks.

Mud Tank Hammer Union Repair and maintenance

3.1 If there is a leakage problem at the joint of the hose joint and the union thread, you can use a pipe wrench to tighten it again, or rewind the sealing tape to tighten.

3.2 Tighten the compression nut or replace the sealing ring when the union male and female heads leak.

3.3 When the joint is stored and not in use, anti-rust oil should be applied to the contact part of the thread and the male and female heads to prevent rust from affecting the use. The high-pressure union sealing ring should be replaced with a new one if stored for more than 1 year.

Contact Us

Tel: +86-29-88680837

Fax: +86-29-88680975

Mobile/Whatsapp/Wechat: +86-13735815206

E-mail: sales@hlsolidscontrol.com