Solids Control Equipment

- Mud Shale Shaker

- Degasser

- Mud Cleaner

- Centrifuge

- Mud Agitator

- Mud Gun

- Jet Mud Mixer

- Centrifugal Pump

- Shear Pump

- Spray Pump

- Vacuum Pump

- Mud Gas Separator

- Ignition

- Drilling Cuttings Dryer

- Filter Press

- Conveyor

Drilling Tools and Spare Parts

- Mud Shale Shaker Spare Parts

- Centrifugal Pump Spare Parts

- Mud Pump Spare Parts

- Centrifuge Spare Parts

- Mud Tank Bottom Valve

- Mud Hopper

- Mud Tank Level Alarm

- Polyurethane Cyclone

- Electric Motor

- WPS Reducer

- Mud Tank Union

- Explosion-proof Water Tank Heater

Mud Treatment System

- Drilling Fluid Solids Control System

- Water-based Mud Treatment System

- Oil based Mud Treatment System

- Trenchless Mud Treatment System

- Mud Mixing System

- Drilling Fluid Cooling System

- Truck mounted Mud Circulation System

- Barite Recovery System

Tank and Steel Structure

Phone: 86-29-88680837

Mail: sales@hlsolidscontrol.com

Add: Room 804, Building 1, Western Cloud Valley Phase II, Fengxi New Town, Xixian New District, Shaanxi Province

XBSY Centrifugal Sand Pump

Product Overview:

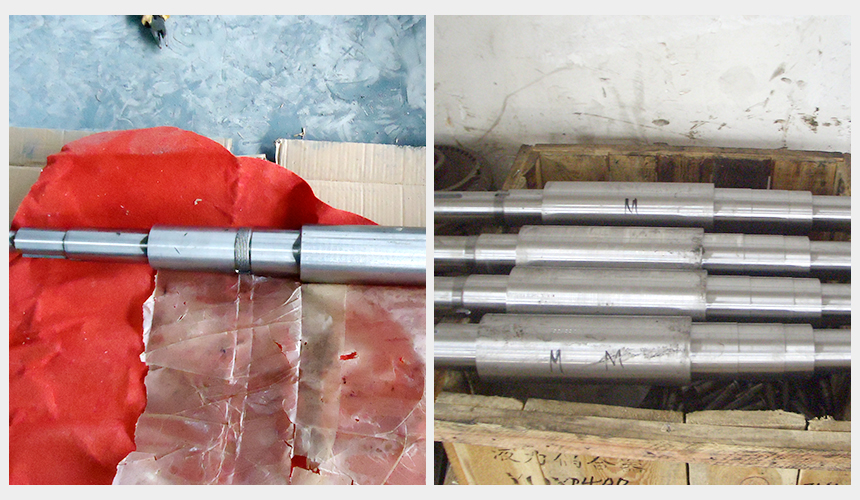

The main function of the XBSY centrifugal sand pump shaft is to transmit power and support the impeller to keep it in normal operation. One end is connected to the motor shaft through a coupling, and the other end supports the impeller for rotating motion. The shaft is equipped with bearings and axial seals,etc.

XBSY Centrifugal Sand Pump Details

The main function of the Centrifugal Sand Pump Shaft is to transmit power and support the impeller to keep it in normal operation. One end is connected to the motor shaft through a coupling, and the other end supports the impeller for rotating motion. The shaft is equipped with bearings, axial seals and other parts.

Pump Shaft Material and Structure

Because the pump shaft is used to transmit power and rotate at high speed, in pumps that transport clean water and other non-corrosive media, they are generally made of 45 steel and are quenched and tempered. In pumps that transport weakly corrosive media such as salt solutions, the pump shaft material is 40Cr and is quenched and tempered. In terms of corrosion resistance, pumps used to transport strong corrosive media such as acid and alkali, the shaft material is generally stainless steel such as Cr18N, Cr18Ni9Ti.

The centrifugal pump shaft is a stepped shaft part, generally as a whole, but in anti-corrosion pumps, due to the high price of stainless steel, sometimes combined parts are used, the part contacting the medium is made of stainless steel, and the bearing and coupling are installed. Use high-quality carbon cable structural steel, bearing connection between stainless steel and carbon steel, and pin reinforcement for interference fit.

SB5x6 ZJ sand pump parts list

|

Item |

Description |

Part No. |

Qty. |

Item |

Description |

Part No. |

Qty. |

|

1 |

Case |

SB56ZJ0001 |

1 |

27 |

Spring washer |

SB56ZJ0027 |

6 |

|

2 |

Impeller-ZJ |

SB56ZJ0002 |

1 |

28 |

Screw bolts |

SB56ZJ0028 |

4 |

|

3 |

Paper gasket-ZJ |

SB56ZJ0003 |

1 |

29 |

Spring washer |

SB56ZJ0029 |

4 |

|

4 |

Stud |

SB56ZJ0004 |

12 |

30 |

Oil gauge |

SB56ZJ0030 |

1 |

|

5 |

Nuts |

SB56ZJ0005 |

12 |

31 |

Plug |

SB56ZJ0031 |

5 |

|

6 |

Spring washer |

SB56ZJ0006 |

12 |

32 |

Slinger |

SB56ZJ0032 |

1 |

|

7 |

Cover of seal |

SB56ZJ0007 |

1 |

33 |

Plug |

SB56ZJ0033 |

2 |

|

8 |

Cover, inboard |

SB56ZJ0008 |

1 |

34 |

Gland bolt |

SB56ZJ0034 |

2 |

|

9 |

Paper gasket |

SB56ZJ0009 |

1 |

35 |

Nuts |

SB56ZJ0035 |

2 |

|

10 |

Oil seal |

SB56ZJ0010 |

1 |

36 |

Washer |

SB56ZJ0036 |

2 |

|

11 |

Oil seal |

SB56ZJ0011 |

1 |

37 |

Screw bolts |

SB56ZJ0037 |

2 |

|

12 |

Bearing |

SB56ZJ0012 |

2 |

38 |

Washer |

SB56ZJ0038 |

2 |

|

13 |

Oil cover |

SB56ZJ0013 |

1 |

39 |

Packing gland set |

SB56ZJ0039 |

1 |

|

14 |

Frame |

SB56ZJ0014 |

1 |

40 |

O-ring |

SB56ZJ0040 |

1 |

|

15 |

Bearing house |

SB56ZJ0015 |

1 |

41 |

Packing |

SB56ZJ0041 |

2 |

|

16 |

O-ring |

SB56ZJ0016 |

1 |

42 |

Pin |

SB56ZJ0042 |

1 |

|

17 |

Bearing |

SB56ZJ0017 |

2 |

43 |

Sleeve,shaft |

SB56ZJ0043 |

1 |

|

18 |

O-ring |

SB56ZJ0018 |

1 |

44 |

Mechanical seal |

SB56ZJ0044 |

1 |

|

19 |

Grease cup |

SB56ZJ0019 |

2 |

45 |

Cover |

SB56ZJ0045 |

1 |

|

20 |

Lock nut |

SB56ZJ0020 |

1 |

46 |

Screw bolts |

SB56ZJ0046 |

4 |

|

21 |

Lock washer |

SB56ZJ0021 |

1 |

47 |

Spring washer |

SB56ZJ0047 |

4 |

|

22 |

Cvoer,out board |

SB56ZJ0022 |

1 |

48 |

Key |

SB56ZJ0048 |

1 |

|

23 |

Oil seal |

SB56ZJ0023 |

1 |

49 |

Key |

SB56ZJ0049 |

1 |

|

24 |

Shaft-ZJ |

SB56ZJ0024 |

1 |

50 |

Cap nuts M30X2-LH |

SB56ZJ0050 |

1 |

|

25 |

Screw bolts |

SB56ZJ0025 |

8 |

51 |

Nuts M30X2-LH |

SB56ZJ0051 |

1 |

|

26 |

Nuts |

SB56ZJ0026 |

4 |

52 |

Washer |

SB56ZJ0052 |

1 |