Product details

The drilling mud shear pump is one of the important equipment for mud configuration in the drilling fluid circulation system. It is mainly used to process chemicals and move soil to achieve the purpose of quickly configuring the drilling fluid.

The shear pump is designed with a special impeller structure, which can generate strong shearing force when the liquid flow passes, and powerfully pulverize and disperse the solid phase such as chemical particles and soil moving in the liquid flow to make the solid phase in the liquid flow. Broken and evenly distributed.

On-site use effect analysis, the use of shear pumps to treat drilling fluid can save more than 20% of the amount of soil removal, and can significantly improve the fluid loss performance and mud cake quality of the drilling fluid, establish a good gel strength, and more effectively protect the well wall and Prevent oil layer pollution and significantly improve the sand-carrying capacity of drilling fluids at low shear rates.

Drilling fluid shear pumps are usually called mud shear pumps, and mud shear pumps are often used in conjunction with jet hoppers. At present, the slurry shear mixing device is widely used in subway shield construction.

Drilling Mud Shear Pump Parameters

|

Model |

Capacity (m3/h) |

Head (m) |

Rotation Speed (r/min) |

Efficiency (%) |

NPSH (m) |

Power (KW) |

|

| Shaft Power | Motor Power | ||||||

|

HJQ5´6J-75kW |

150 |

30 |

2150 |

28 |

3 |

46 |

75 |

|

HJQ5´6J-55kW |

140 |

26 |

2050 |

28 |

3 |

35 |

55 |

|

HJQ5´6J-45kW |

105 |

24 |

1750 |

28 |

2.8 |

25 |

45 |

|

HJQ5´6J-37kW |

105 |

24 |

1750 |

28 |

2.8 |

25 |

37 |

Drilling Mud Shear Pump Features

1. The pump body is made of wear-resistant alloy cast iron, which has a longer service life.

2. The bearing adopts well-known brand bearings, and the quality is guaranteed.

3. The mechanical seal is used as the main component, and the packing is supplemented by the combination of the seal. The mechanical seal is made of cemented carbide, and the service life is 5 times that of ordinary.

4. The wall of the pump casing is thick, and it is made of precision casting, with good wear resistance and exquisite appearance.

5. Imported fluorine rubber oil seal is selected for the oil seal, which has good cooling performance. Ensure the normal operation of the sand pump.

6. Special impeller and shearing plate are used, and the shearing efficiency is more than 95%. The impeller material is made of high chromium alloy, and the shearing plate is stainless steel, which has good wear resistance and corrosion resistance.

Why choose us?

HL Factory

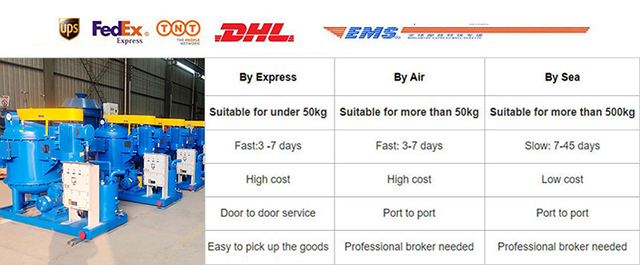

About Shipping