Product details

Xi'an HL Petroleum BRS Barite Recovery System is an advanced system for oil drilling fluid purification and barite recovery and reuse. In order to meet the development needs of oil drilling solids control technology, our company uses ordinary barite recovery process On the basis of the advanced technology at home and abroad, it not only solves the problem of the clogging of the centrifuge due to the high mud density in the drilling fluid barite recovery process, but also solves the problem of barite agglomeration after recovery.

The BRS barite recovery system consists of a frequency conversion high-speed centrifuge, a medium-speed centrifuge, and recovery equipment. The medium-speed centrifuge recovers the barite, and the high-speed centrifuge removes the harmful solid phase. The recovered barite passes through the spray device and then returns to the drilling fluid circulation system, achieving recovery, mixing and utilization at the same time, and the entire cycle The organic combination of the system.

The BRS barite recovery system uses a new type of variable frequency centrifuge with strong adaptability and precise control of the separation point, so that the maximum slurry density can be 2.8g/cm3. Recoverable barite particle size 7-75μm, weighted mud processing capacity ≥ 4m3/h (2.8g/cm3), 15m3/h (1.8g/cm3). Non-weighted mud processing capacity ≥ 40m3/h (1.3g/ cm3).

This system is not only suitable for the treatment of weighted mud, but also for the treatment of non-weighted mud.

Why choose us?

HL Factory

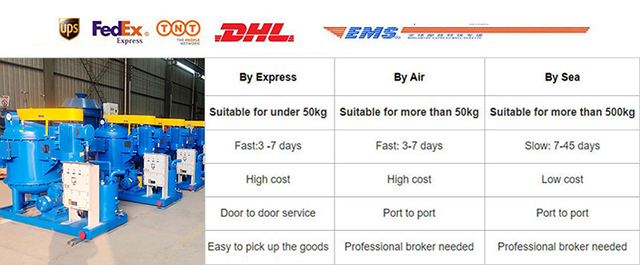

About Shipping