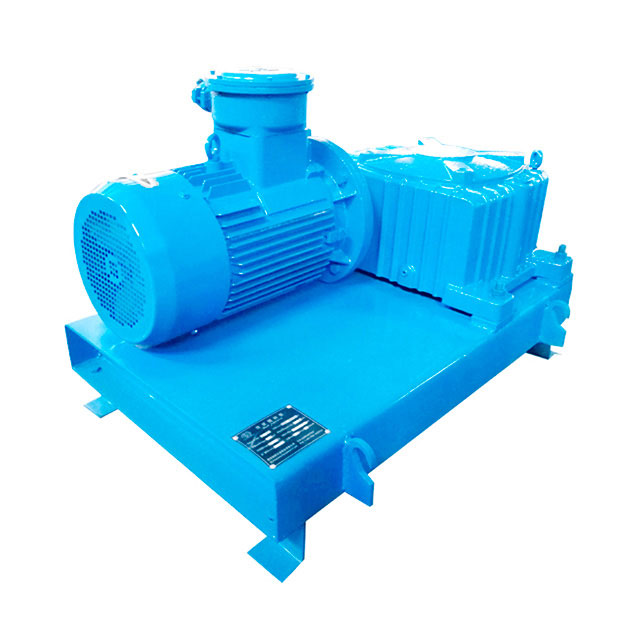

Product details

The Drilling fluid agitator is installed on the mud circulation tank, in order to ensure the uniform performance of the drilling fluid and suspend the solid particles, so that the drilling fluid additives accelerate the mixing, reaction and dissolution, the Oilfield drilling mud agitator increases the contact area between the phase boundaries , So that the two phases interact at a greater speed.

Flange Connection Mud Agitator Features

1). No exposed transmission parts, greatly improving the safety of on-site personnel

2). No coupling is required, and subsequent maintenance is convenient and quick;

3). The dimensions of the direct connection type and the coupling type base are exactly the same, and the tank matching installation dimensions remain unchanged;

4). Short drive shaft distance, high transmission efficiency;

5). The shaft hole is matched and installed to greatly improve the concentricity and reduce the wear of the bearing oil seal of the reducer motor;

6). Normal wear and tear, without wearing parts, reducing labor intensity;

7). Compact structure, good meshing performance, reliable work;

8). Flange connection of motor and reducer has good sealing performance, which is more suitable for working in harsh outdoor conditions.

Flange Connection Mud Agitator Parameters

| Model | HJB5.5 | HJB7.5 | HJB11 | HJB15 | HJB18.5 | HJB22 |

| Power(kw) | 5.5 | 7.5 | 11 | 15 | 18.5 | 22 |

| Rated Revolution(r/min) | 1440 | 1440 | 1460 | 1460 | 1470 | 1470 |

| Impeller’s Revolution (r/min ) | 72 | 72 | 73 | 73 | 73 | 73 |

| Impeller’s Dia.(mm) | 800 | 860 | 940 | 1040 | 1140 | 1240 |

| Weight(kg) | 295 | 400 | 462 | 563 | 785 | 815 |

|

Dimensions (mm) (L×W×H) |

954×549 ×583 |

1101×664 ×623 |

1222×664 ×665 |

1334×734 ×685 |

1445×888 ×770 |

1465×888 ×770 |

Suspending solid particles in the drilling fluid is the main function of the Oilfield drilling mud agitator. Drill cuttings are the main component of the harmful solid phase. To remove the harmful solid phase, they must be suspended, and then injected into the de-sander, desilter and centrifuge to achieve the useful solid phase, such as various aggravating materials (red Iron ore powder, barite powder) and a small amount of bentonite also need to be stirred and suspended evenly to ensure that the density and other properties of the drilling fluid remain stable. Therefore, the solid-control stirrer is required to work reliably and continuously to avoid the phenomenon of solid-phase release and precipitation.

Contact Us

Sales: Cici

Phone/Whatsapp/Wechat: +86-13735815206

E-mail: sales@hlsolidscontrol.com

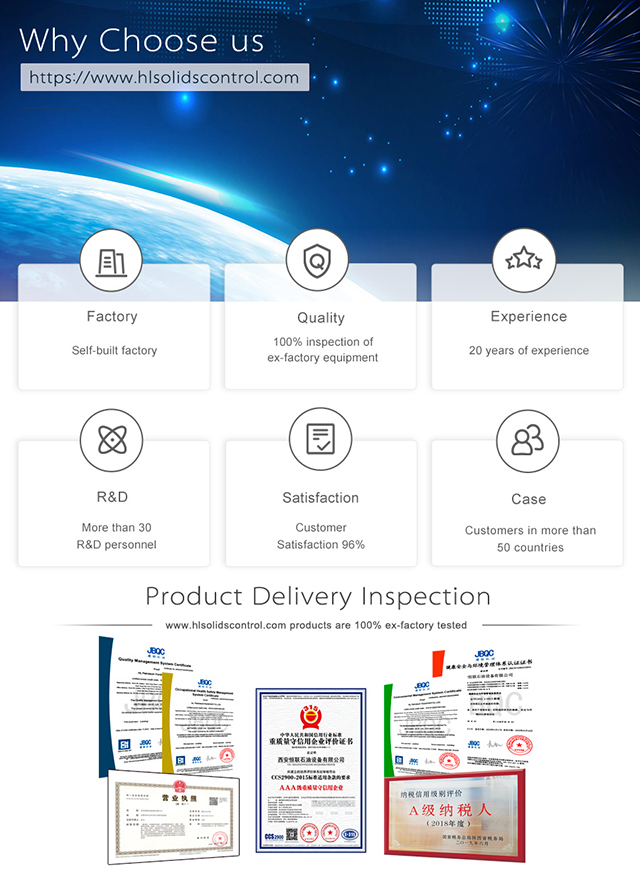

Why choose us?

HL Factory

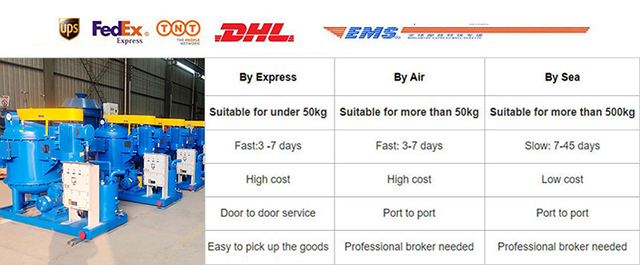

About Shipping