Product details

Nested water tank is mainly used for oil drilling production water supply and domestic water supply, and is an essential water supply equipment. HL Petroleum can currently produce various specifications of set water tanks, domestic water tanks, cooling water tanks, industrial water tanks, and can be equipped with various explosion-proof water pumps, electric control cabinets, switches, lamps and heat preservation and heating facilities according to customer needs. It satisfies the requirements of different environmental conditions in wellsites and civil use.

The cooling water tank has a set of effective cooling equipment. Including fan, radiator, fan housing, radiator guard and other parts. When in use, connect the upper interface of the cooling device to the brake system, and the lower interface to the tank. In this way, the hot water from the brake system can flow back into the water tank after being cooled. The cooling water can be returned to the brake system again under the action of the water tank pump unit, so as to realize the circulation of water. The skid-mounted base of the cooling system allows the tank to be lifted by a crane or hauled.The drinking water tank is a domestic water tank developed by our factory that meets the drinking water standard. Since its application, it has been praised by the majority of drilling staff and improved the living conditions of the well site.

Our company's nested water tank is divided into a top tank and a bottom tank. The top tank is small and the bottom tank is large. When working, the top tank is seated on the bottom tank by turning the hook frame to provide water supply pressure for the workplace. The bottom tank is a reserve water tank, equipped with a water pump, which can supply water to the top tank at any time. When transporting, empty the water tank, and the top tank can be stowed away by the flip hook, which can be put into the bottom tank for easy transportation.

Nested Water Tank Parameter

|

Tank type |

Water tank and Nested water tank |

|

Tank volume |

30~100m³(According to customer requirements) |

|

Tank pressure |

Atmospheric |

|

Tank corrosion treatment |

Inside: first sandblasting, and then spray water for water-based corrosion protection inside the tank Outside:Sandblasting first, then epoxy zinc-rich primer + intermediate paint + polyurethane topcoat |

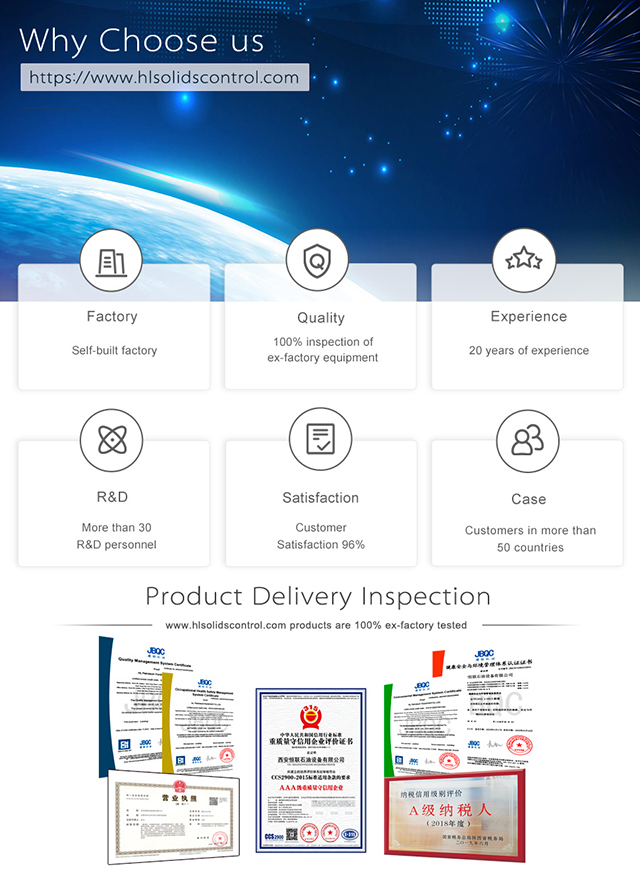

Why choose us?

HL Factory

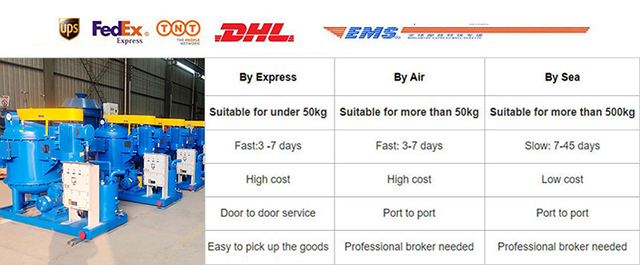

About Shipping