Product details

Today I will introduce a new type of mud mixing system-HHX-15-Q gasoline engine mud mixing system. This is a mud mixing system specially customized for our foreign customer, and it is applied to the trenchless tunnel construction site. This device is a special equipment for preparing or weighting drilling mud. It can disperse and evenly add bentonite, barite, and polymer into the drilling fluid, thereby adjusting the mud density, viscosity, water loss, and other important performance parameters.

This mixing system mainly consists of a set of 15m³ (4000 gallons) mud tank, a Honda gasoline engine mud pump and a jet mixing hopper. The processing capacity can reach 132m³/h. The pump casing is made of aluminum alloy, the impeller and the flowing parts are made of ductile iron, which has strong wear and corrosion resistance, and can transfer sandy mud. The tank inside is also equipped with an anti-sedimentation injection system.

We adopt a corrugated structure for the mud tank. The base is made of national standard I-beam steel as the bottom beam. Hanging shafts are set at both ends to make a ship-shaped skid-mounted structure, which can be towed short distances on site and can also be hoisted and transported. The top of the tank is laid with anti-skid steel plates to ensure the safety of workers, On the tank's surface, there are manholes for convenient liquid level observation and maintenance by workers. Additionally, a liquid level gauge is installed on the side of the tank, which is convenient for operators to observe the liquid level in real time and replenish or discharge mud in time!

This gasoline engine mud mixing system not only has the function of adding materials, but also has the functions of transferring and mixing mud. It is a multi-purpose machine. The biggest feature of this system is that it uses a gasoline engine as power and does not require an external power supply, which greatly reduces the power consumption problem in field construction. Just add gasoline on time and it can be used, which increases the convenience of on-site construction!

We can also customize mixing systems with different capacities and models, welcome to send inquiry to us: sales@hlsolidscontrol.com if you want to know more about it!

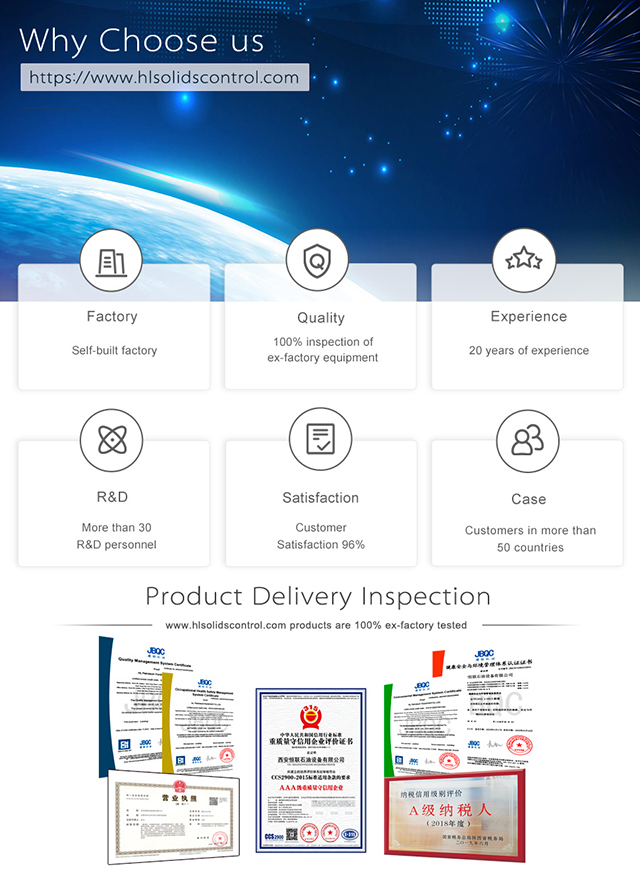

Why choose us?

HL Factory

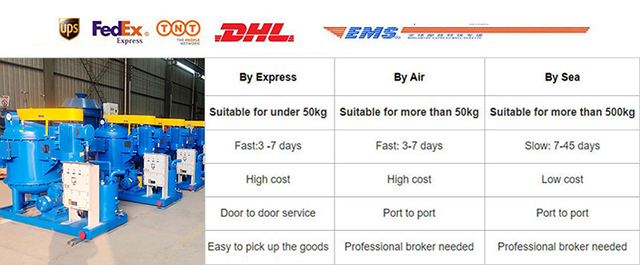

About Shipping