Product details

HL HCP Series sand pumps are 100% interchangeable with Mission Magnum pumps. The HL HCP Series centrifugal pump head is an important part of the Mission centrifugal pump, which refers to the rest of the Mission pump except the motor and pump body, including impellers, bearings, oil rings, sealing rotating parts (including shafts) and other components. The pump head is made of different materials such as metal, plastic, rubber, etc. according to different needs, and has good high temperature resistance, corrosion resistance and wear resistance.

HL HCP Mission centrifugal pump product type

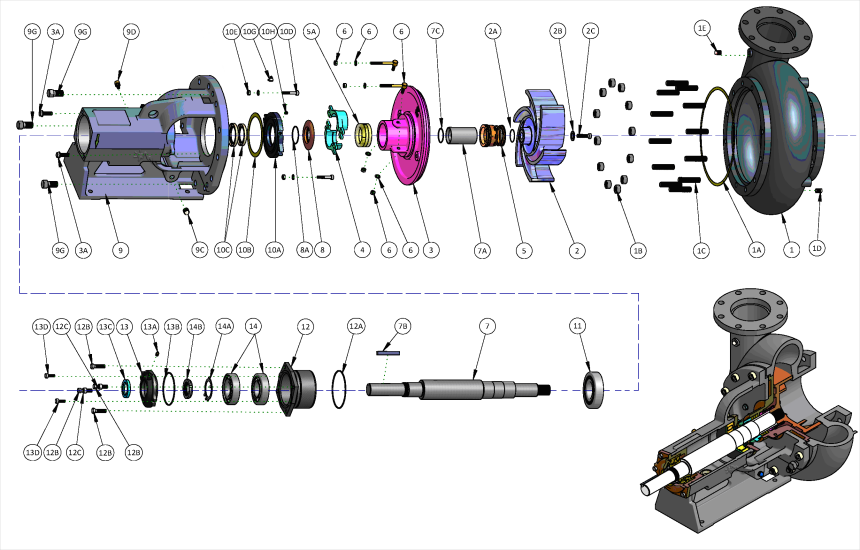

HL HCP series 8×6×14, 8×6×11 model Mission pump is mainly used to provide a certain displacement and pressure for desander, desilter, mixing pump, mud pump. 6×5×14, 6×5×11 model Mission pump is mainly used for truck-mounted drilling rig. 4×3×13 model Mission pump is mainly used in conjunction with metering tank, also known as metering pump. 3×2×13 model Mission pump is mainly used in conjunction with water tank or water cooling system, also known as clean water pump.HL HCP Mission centrifugal pump structure explosion diagram

| Serial number | Part name | Part number | Quantity | Material |

| 1* | Pump casing | See the table below | 1 | Hard Iron |

| 1A | Pump casing gasket | 10399-46-1 | 1 | Vellumoid |

| 1B | Pump casing tightening nut 3/4 | 3932-61 | 12 | Stl |

| 1C | Pump casing tightening bolt 3/4X85 | 3862-76 | 12 | Stl |

| 1D | Square head screw plug 3/8 | 8505-04-01 | 1 | Stl |

| 1E | Square head screw plug 1/2 | 8505-04-01 | 1 | Iron |

| 2* | Impeller | See the table below | 1 | Iron |

| 2A | Impeller | See the table below | 1 | Viton |

| 2B | O-ring 46.2X1.8 | 19110-72 | 1 | Stl |

| 2C | Impeller locking washer | 1 | Stl | |

| 3* | Impeller locking bolt | 1 | Hard Iorn | |

| 3* | Mechanical seal box | 22223-01-30 | 1 | Hard Iorn |

| 3A | Packaging seal box | 20614-01-30 | 2 | Stl |

| 4 | Mechanical seal box tension bolt | 3861-117 | 1 | Bronze |

| 5 | Packaging sleeve | 20622A | 1 | Tungsten Carbide |

| 5A | Mechanical seal | 22451-1 | 3 | Kevlar |

| 6 | Packaging 12X12 | 25014-04M-B | 2 | Stl |

| 7 | L bolt assembly | B3701A | 1 | AISI 4140 |

| 7A | Wear-resistant sleeve (mechanical seal) | 20943-21 | 1 | AISI E7140 |

| 7A | Wear-resistant sleeve (packing seal) | 20613-21G-7A | 1 | AISI E7140 |

| 7B | Key | 4372-5-21 | 1 | 416SS |

| 7C | O-ring 51.5X2.65 | 23444-01-72 | 1 | Viton |

| 8 | Water retaining ring | 22210-1A | 1 | Bronze |

| 8A | O-ring 63X2.65 | 1 | Viton | |

| 9 | Bearing seat | 20618-12-1 | 1 | Cast Iron |

| 9A | ||||

| 9B | ||||

| 9C | Square head screw plug 1/2 | 8505-05 | 1 | Iron |

| 9D | Breathing nozzle | 8267-01 | 1 | Stl |

| 9E | ||||

| 9F | ||||

| 9G | Pump housing push-out bolt | 2538-1A | 3 | Stl |

| 10A | Inner bearing cover | 20626 | 1 | Iron |

| 10B | Inner bearing cover gasket | 20625 | 1 | Vegetable Fiber |

| 10C | Oil seal | 20619-01 | 2 | Buna-n |

| 10D | Inner bearing cover bolt | 3861-1 | 2 | Stl |

| 10E | Inner bearing cover nut | 3932-2 | 2 | Stl |

| 10F | ||||

| 10G | Grease nipple NPT1/8 | 21641-01 | 1 | Stl |

| 11 | Inner bearing NUP313E | N/A | 1 | Vendor |

| 12 | Axial adjustment sleeve | 20624-01-01 | 1 | Iron |

| 12A | O-ring 140X3.55 | 7496-253 | 1 | Buna-n |

| 12B | Axial adjustment sleeve bolt | 3861-138 | 4 | Stl |

| 12C | Axial adjustment sleeve push-out nut | 3932-62 | 2 | Stl |

| 13 | Outer bearing cover | 20617-01-01 | 1 | Iron |

| 13A | Grease nipple NPT1/8 | 1 | Stl | |

| 13B | O-ring 120X3.55 | 7496-26 | 1 | Buna-n |

| 13C | Oil seal 47.63X69.85X9.525 | 20619-02 | 1 | Buna-n |

| 13D | Outer bearing cover bolt | 3861-139 | 2 | Stl |

| 14 | Bearing 7311B/DB | N/A | 1 | Vendor |

| 14A | Locking washer | 6124-4 | 1 | Stl |

| 14B | Locking nut | 6123-4 | 1 | Stl |

| 1* | Pump casing, 3x2x13 | 19203-01-30A | 1 | Hard Iron |

| 1* | Pump casing, 4x3x13 | 19205-01-30A | 1 | Hard Iron |

| 1* | Pump casing, 5x4x11 | 19222-01-30A | 1 | Hard Iron |

| 1* | Pump casing, 6x5x11 | 19122-01-30A | 1 | Hard Iron |

| 1* | Pump casing, 6x5x14 | 19123-01-30A | 1 | Hard Iron |

| 1* | Pump casing, 8x6x11 | 19763-01-30A | 1 | Hard Iron |

| 1* | Pump casing, 8x6x14 | 19117-01-30A | 1 | Hard Iron |

| 1* | Pump casing, 10x8x14 | 20937-01-30A | 1 | Hard Iron |

| 2* | Impeller, 3x2x13 pump | 19204-XX-30 | 1 | Hard Iron |

| 2* | Impeller, 4x3x13 pump | 19206-XX-30 | 1 | Hard Iron |

| 2* | Impeller, 5x4x14 pump | 19224-XX-30 | 1 | Hard Iron |

| 2* | Impeller, 6x5x11 pump | 19121-XX-30 | 1 | Hard Iron |

| 2* | Impeller, 6x5x14 pump | 19121-XX-30 | 1 | Hard Iron |

| 2* | Impeller, 8x6x11 pump | 19121-XX-30 | 1 | Hard Iron |

| 2* | Impeller, 8x6x14 pump | 19116-XX-30 | 1 | Hard Iron |

| 2* | Impeller, 10x8x14 pump | 21867-XX-30 | 1 | Hard Iron |

| XX or A0 - Impeller Designator - The first column X is equal to the impeller diameter in inches minus 4. Thus 10"= 6, 9"= 5, 8"=4, etc… 14" uses the letter A. | ||||

| The second X is a multiple of 1/8". So 1/8"= 1, 1/4"= 2, 1/2"= 4, etc… So a 10.5" impeller is coded 64, a 12" impeller is coded 80, a 13.25" impeller is coded 92 etc… | ||||

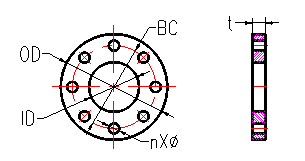

HL HCP Mission centrifugal pump Head dimensions

| Size | ID | OD | BC Inches |

BC Metric |

T thickness |

N Number of holes |

Aperture Φ |

| (Inch) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | |

| 2 | 50.8 | 152.4 | 120.7 | 125 | 16 | 4 | 19 |

| 3 | 76.2 | 190.5 | 152.4 | 160 | 19 | 4 | 19 |

| 4 | 101.6 | 228.6 | 190.5 | 180 | 24 | 8 | 19 |

| 5 | 127 | 254 | 215.9 | 210 | 24 | 8 | 22.2 |

| 6 | 152.4 | 280 | 241.3 | 240 | 25 | 8 | 22.2 |

| 8 | 203.2 | 343 | 298 | 295 | 28.5 | 8 | 22.2 |

| 10 | 254 | 330 | 362 | 350 | 30 | 12 | 25.4 |

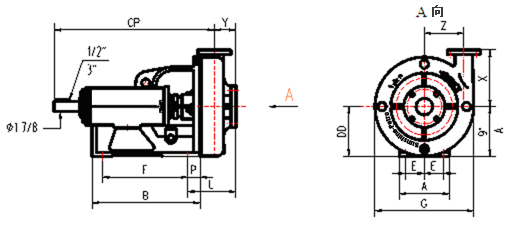

| Pump Model | A (mm) |

B (mm) |

E (mm) |

F (mm) |

G (mm) |

L (mm) |

P (mm) |

X (mm) |

Y (mm) |

Z (mm) |

CP (mm) |

DD (mm) |

weight (Kg) |

| 3x2x13 | 228.6 | 498.5 | 88.9 | 392.1 | 454 | 222.2 | 58.7 | 260 | 95.3 | 177.8 | 743 | 227 | 200 |

| 4x3x13 | 228.6 | 498.5 | 88.9 | 392.1 | 454 | 238 | 58.7 | 260 | 108 | 171.5 | 746 | 227 | 200 |

| 6x5x11 | 228.6 | 498.5 | 88.9 | 392.1 | 454 | 306.4 | 58.7 | 280 | 146 | 152.4 | 777.8 | 227 | 230 |

| 6x5x14 | 228.6 | 498.5 | 88.9 | 392.1 | 533.4 | 306.4 | 58.7 | 280 | 146 | 152.4 | 777.8 | 266.7 | 250 |

| 8x6x11 | 228.6 | 498.5 | 88.9 | 392.1 | 508 | 336.5 | 58.7 | 355.5 | 159 | 212.7 | 793.8 | 254 | 265 |

| 8x6x14 | 228.6 | 498.5 | 88.9 | 392.1 | 598.5 | 336.5 | 58.7 | 355.5 | 159 | 212.7 | 793.8 | 300 | 280 |

FAQ

Q1: How can I make order online?

A: Send email or message(whatsApp/ wechat) us.you can ask any question ,after we confirm the detail, we can make order.

Q2: Do you have MOQ limit?

A: The MOQ is 1 set.

Q3: What's your warranties?

A: 1 year after delivery

Q4: Can I buy parts separately?

A: Yes, all of the pump spare parts can buy separately.

Why choose us?

HL Factory

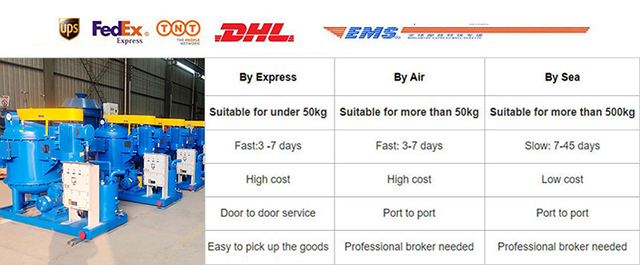

About Shipping