Product details

In a centrifugal pump, the term "sleeve" typically refers to a component that acts as a protective covering or lining for the pump shaft. The sleeve is designed to provide support and prevent direct contact between the shaft and the pump casing or volute. It helps to reduce wear and minimize friction between the rotating shaft and the stationary parts of the pump. The sleeve is usually made of a durable and corrosion-resistant material, such as stainless steel or bronze, to withstand the harsh operating conditions of the pump. It is precisely machined to fit tightly around the shaft and may have specific features like oil grooves or cooling passages to enhance lubrication and heat dissipation. The sleeve serves as a critical component in maintaining the integrity and longevity of the pump by protecting the shaft from excessive wear and damage. It also helps to maintain the hydraulic efficiency of the pump by reducing energy losses due to friction.

Centrifugal Pump Sleeve Pictures

Centrifugal Pump Sleeve Features

In a centrifugal pump, the sleeve serves several important functions.:

1. Bearing Support: The sleeve provides support for the pump's shaft bearings. It acts as a housing or enclosure for the bearings, ensuring proper alignment and reducing vibration and wear. The sleeve helps maintain the position and stability of the shaft, allowing it to rotate smoothly.

2. Shaft Protection: The sleeve acts as a protective barrier for the pump shaft, shielding it from contact with the pumped fluid. It helps prevent corrosion, erosion, and other forms of damage to the shaft, thereby increasing its durability and lifespan.

3. Impeller Positioning: The sleeve plays a role in positioning the impeller within the pump casing. It helps maintain the precise axial and radial alignment of the impeller, ensuring optimal performance and efficiency. The sleeve acts as a guide for the impeller, keeping it centered and preventing unwanted movement.

4. Seal Chamber Enclosure: In some centrifugal pumps, the sleeve forms part of the seal chamber, which houses the mechanical seals. Mechanical seals are used to prevent leakage between the rotating shaft and the stationary pump casing. The sleeve provides a secure enclosure for the seal chamber, helping to maintain the seal's integrity and effectiveness.

5. Ease of Maintenance: The sleeve is designed to be easily removable, allowing for convenient maintenance and repair of the pump. When necessary, the sleeve can be detached from the pump casing, providing access to the internal components for inspection, cleaning, or replacement.

Overall, the sleeve in a centrifugal pump plays a vital role in supporting the shaft bearings, protecting the shaft, facilitating impeller positioning, enclosing the seal chamber, and enabling maintenance procedures.

Xi'an HL can supply centrifugal pump parts that can replace. the main accessories are pump case, impeller, cover of seal, mission pump impeller, strengthened board, shear plate, mechanical seal, cover, pump jointer, motor jointei, cover,outboard, sleeve, lock nuts, nuts, domed cap nuts, oil seal, v-belt, packing, retainer, bearing washer, shaft, washer, couplingpin, flat key, etc.

More Centrifugal Pump Accessories

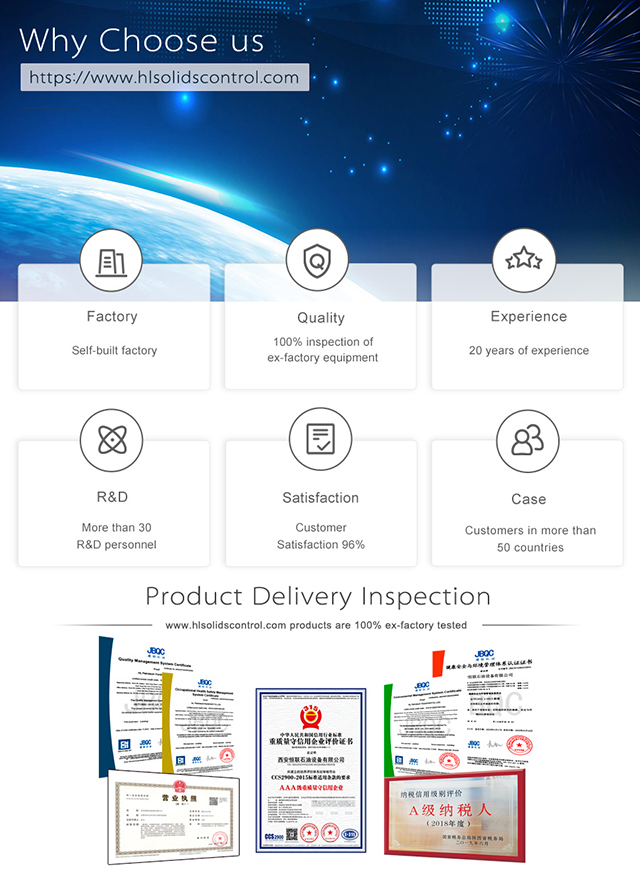

Why choose us?

HL Factory

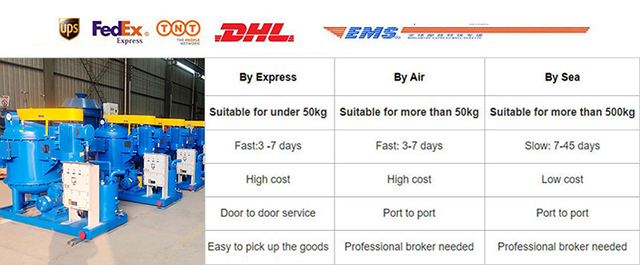

About Shipping