Product details

The wave shaker screen is commonly used in various industries such as oil drilling, solids control systems, coal mining, and ore processing. Its unique design helps to optimize the efficiency of the screening process by minimizing clogging and increasing the contact time between the material and the screen surface. This results in improved screening accuracy and a higher throughput rate.1. Strong Solid-Liquid Separation Capability: The wave shaker screen effectively separates solid particles from liquids through its wave-shaped structure and appropriate opening size. It rapidly drains liquids while retaining solid particles, providing efficient solid-liquid separation performance.

2. Reduced Clogging and Wear: The wave-shaped structure helps minimize clogging and wear, preventing material adhesion and accumulation on the screen mesh. This reduces maintenance and screen replacement frequency, improving equipment reliability and lifespan.

3. Improved Screening Efficiency: The wave-shaped structure of the wave shaker screen increases the screening surface area, expanding the screening capacity and enhancing screening efficiency. It more effectively separates target particles and provides more accurate particle size distribution.

4. Versatile Applications: The wave shaker screen finds wide applications in industries such as oil drilling, solids control systems, ore processing, chemical, and food processing. It is suitable for various types of materials, including solids, liquids, and powders.

5. Durability and Reliability: Wave shaker screens are typically made from corrosion-resistant materials, offering high strength and durability for long-term use in challenging working environments. They can withstand vibrations, high loads, and frequent usage, providing stable and reliable screening performance.

Why choose us?

HL Factory

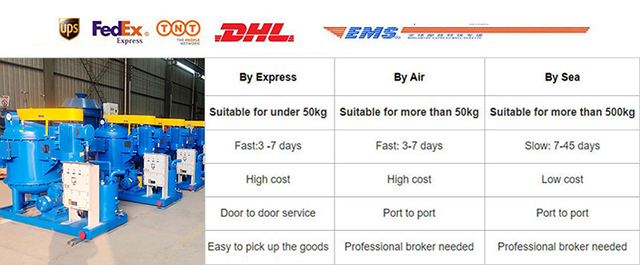

About Shipping