Product details

The drilling cuttings dryer is a single-stage continuous working vertical scraper discharge centrifuge. The drill cuttings dryer mainly uses centrifugal force to separate the oil-based drill cuttings and the oil and water in the composite-base drill cuttings, so as to achieve the purpose of reducing harmful substances and recovering useful drilling fluid.

Drill cuttings dryer is often used in the field of environmentally friendly waste mud treatment in oilfields. It can effectively recover the oil content in drill cuttings, effectively achieve solidification and transportation, and meet the requirements of environmental protection regulations. It is specially used to treat drills discharged from drilling fluid shakers. Chips, suitable for oil machine mud (OBM), composite base mud (SBM)

Currently, drill cuttings dryersare widely used in domestic oilfield drilling

Drilling Cuttings Dryer Components

Screen basket, spiral discharge rotor, bell cover, cloth cone, transmission part, lubrication system

Drilling Cuttings Dryer Features

1. The speed can reach 900RPM, which can form a separation factor of 420G and effectively separate the liquid in the cuttings.

2. Solid-liquid separation can reduce the mud content in drilling cuttings and reduce the amount of waste disposal.

3. The discharge scraper is made of hard alloy material and has a long service life.

4. Effectively separate and recover a larger proportion of mud, and reuse it in the mud circulation system, which can recover the mud lost due to the running of the vibrating screen, the moving derrick and the blockage of the screen.

5. The drum of the drying machine is made of alloy material, which is corrosion-resistant.

6. The discharge port can be equipped with a screw conveyor to facilitate the transportation of dry cuttings and the continuous operation of the equipment.

7. It is convenient and fast to use, which can reduce product cost.

Drilling Cuttings Dryer Application

1). Onshore and offshore oil and gas drilling

2). CBM excavation

3). Trenchless directional crossing

4). Piling works

5). Waste water, mud treatment and other projects.

Contact Us

Tel: +86-29-88680837

Fax: +86-29-88680975

Mobile/Whatsapp/Wechat: +86-13735815206

E-mail: sales@hlsolidscontrol.com

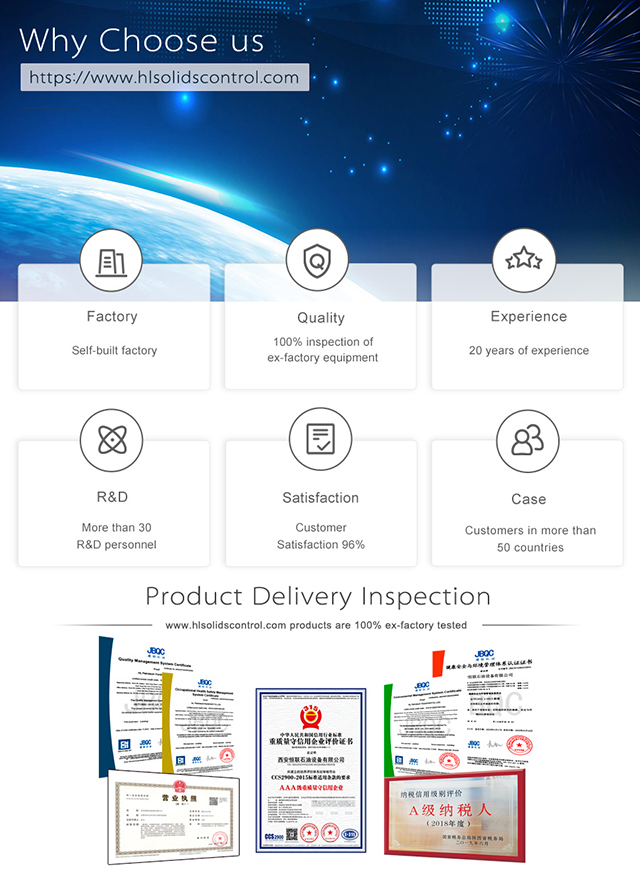

Why choose us?

HL Factory

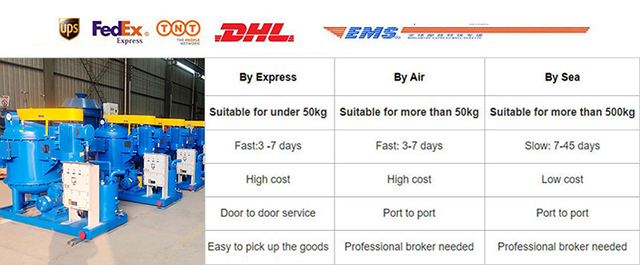

About Shipping