WhatsApp: 86-13735815206 / 86-17392256505

WeChat: 86-13735815206 / 86-17392256505

Phone: 86-29-88680837

Mail: sales@hlsolidscontrol.com

Add: Room 804, Building 1, Western Cloud Valley Phase II, Fengxi New Town, Xixian New District, Shaanxi Province

WeChat: 86-13735815206 / 86-17392256505

Phone: 86-29-88680837

Mail: sales@hlsolidscontrol.com

Add: Room 804, Building 1, Western Cloud Valley Phase II, Fengxi New Town, Xixian New District, Shaanxi Province

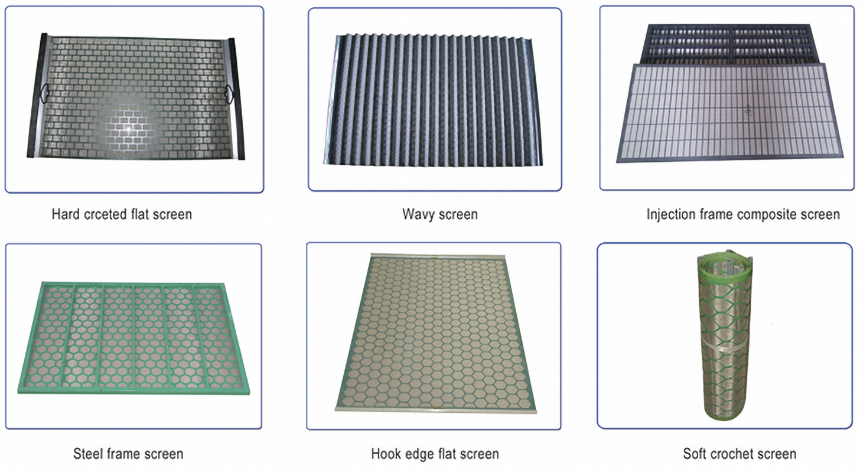

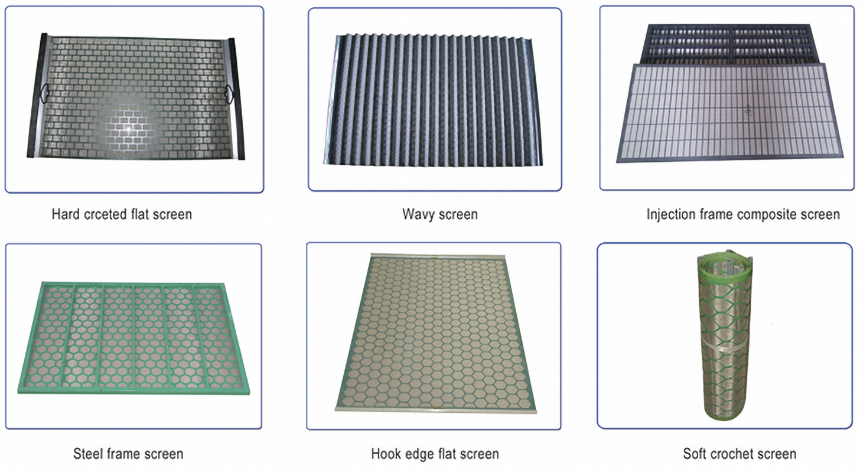

What are the types of Shale Shaker Screens?

Time: 2023-08-09 Source: Author: hlsolidscontrol

Shale shaker screens are an essential component of drilling equipment used in the oil and gas industry to separate solids from drilling fluids. These screens come in various types and designs to effectively filter and remove different-sized particles from the drilling mud. Here are some common types of shale shaker screens:

Flat Shale shaker Screen: This is a basic type of screen that consists of a flat, smooth surface. It is often used to remove larger solids from drilling fluid.

Wavy Shale shaker Screen: Wavy screens have a corrugated or wavy surface, which helps increase the effective screening area and enhances the efficiency of solids separation.

Injection Frame Composite Shale shaker Screen: These screens are made from a composite material and have a metal or plastic injection-molded frame. They are known for their durability and are resistant to wear and tear.

Steel Frame Shale shaker Screen: Steel frame screens are constructed with a rigid steel frame and a mesh screen. They are robust and can handle heavy loads of solids during the drilling process.

Hook Edge Flat Shale shaker Screen: Similar to the flat screen, the hook edge flat screen has a flat surface, but it features a hook-shaped edge that allows for easy installation and removal from the shale shaker.

Soft Crochet Shale shaker Screen: Soft crochet screens are designed with a fabric-like material that is flexible and easy to install. They are often used in situations where fine solids need to be separated from drilling fluid.

Hard Crimped Flat Shale shaker Screen: This type of screen has a crimped or corrugated surface, providing increased strength and rigidity. It is commonly used for applications with higher demands on screen durability.

It's important to note that shale shaker screen designs and types can vary between manufacturers and specific drilling applications. The choice of the appropriate shale shaker screen type depends on factors such as the size of solids present in the drilling fluid, the desired separation efficiency, and the operational conditions of the drilling operation.

Flat Shale shaker Screen: This is a basic type of screen that consists of a flat, smooth surface. It is often used to remove larger solids from drilling fluid.

Wavy Shale shaker Screen: Wavy screens have a corrugated or wavy surface, which helps increase the effective screening area and enhances the efficiency of solids separation.

Injection Frame Composite Shale shaker Screen: These screens are made from a composite material and have a metal or plastic injection-molded frame. They are known for their durability and are resistant to wear and tear.

Steel Frame Shale shaker Screen: Steel frame screens are constructed with a rigid steel frame and a mesh screen. They are robust and can handle heavy loads of solids during the drilling process.

Hook Edge Flat Shale shaker Screen: Similar to the flat screen, the hook edge flat screen has a flat surface, but it features a hook-shaped edge that allows for easy installation and removal from the shale shaker.

Soft Crochet Shale shaker Screen: Soft crochet screens are designed with a fabric-like material that is flexible and easy to install. They are often used in situations where fine solids need to be separated from drilling fluid.

Hard Crimped Flat Shale shaker Screen: This type of screen has a crimped or corrugated surface, providing increased strength and rigidity. It is commonly used for applications with higher demands on screen durability.

It's important to note that shale shaker screen designs and types can vary between manufacturers and specific drilling applications. The choice of the appropriate shale shaker screen type depends on factors such as the size of solids present in the drilling fluid, the desired separation efficiency, and the operational conditions of the drilling operation.