WhatsApp: 86-13735815206 / 86-17392256505

WeChat: 86-13735815206 / 86-17392256505

Phone: 86-29-88680837

Mail: sales@hlsolidscontrol.com

Add: Room 804, Building 1, Western Cloud Valley Phase II, Fengxi New Town, Xixian New District, Shaanxi Province

WeChat: 86-13735815206 / 86-17392256505

Phone: 86-29-88680837

Mail: sales@hlsolidscontrol.com

Add: Room 804, Building 1, Western Cloud Valley Phase II, Fengxi New Town, Xixian New District, Shaanxi Province

The difference between single-stage and multi-stage centrifugal pump

Time: 2024-06-24 Source: Centrifugal Pump Author: Mrek

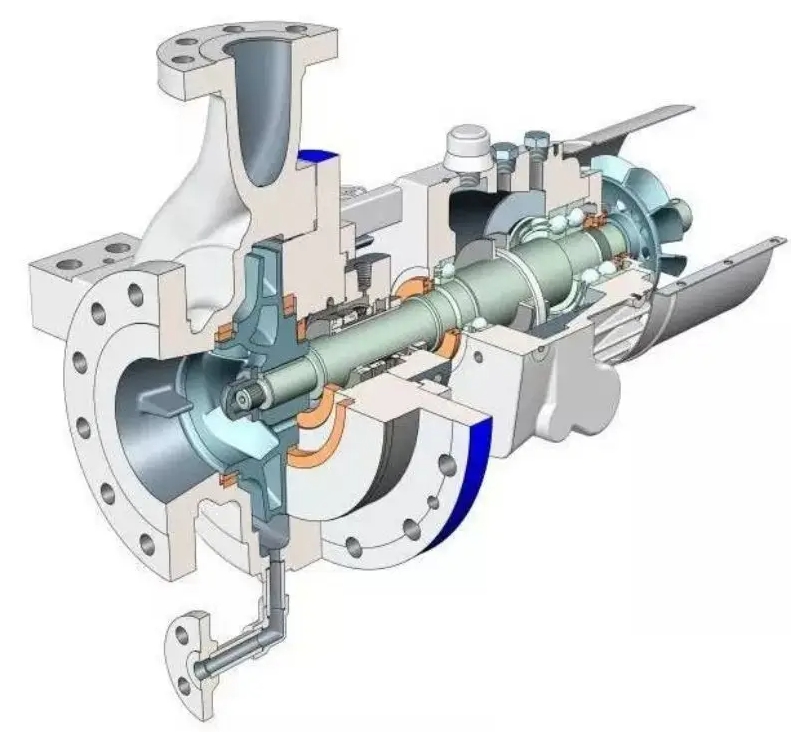

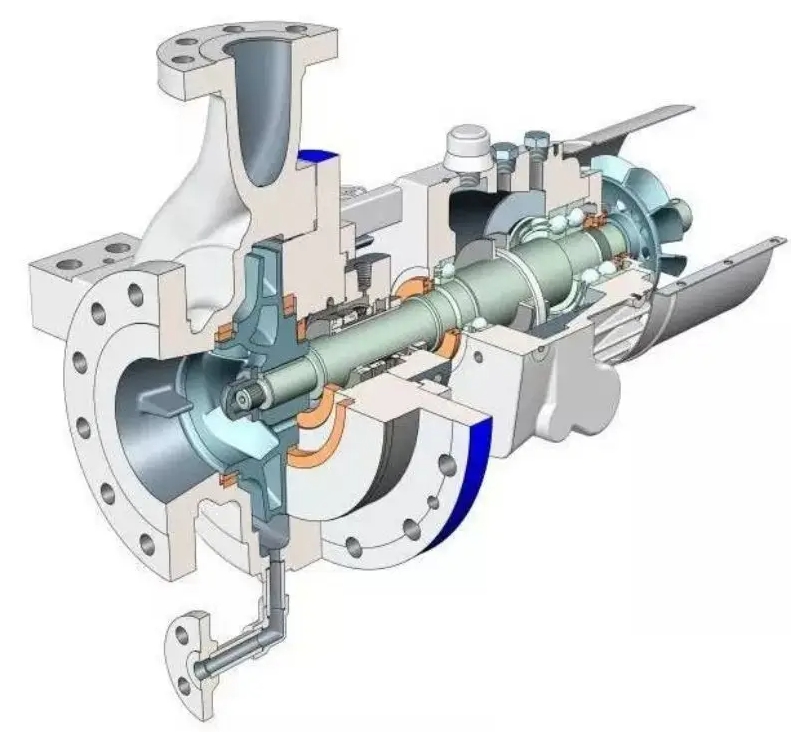

Centrifugal pump are medium transmission equipment that transports liquids through centrifugal force, so they are called centrifugal pumps.

Centrifugal pumps have stable flow, smooth operation, simple maintenance, and a wide range of media applications, so they are widely used in oil drilling and industrial production.

Centrifugal pumps are divided into different types according to different internal structures and different working environments, for example. Centrifugal pumps are divided into single-stage pumps (single impeller) and multi-stage pumps (multi-impellers) according to the number of working impellers.

According to the pressure level of the pump, they are divided into low-pressure pumps, medium-pressure pumps and high-pressure pumps.

According to the impeller water inlet method, they are divided into single-side water inlet pumps and double-side water inlet pumps.

According to the direction of the pump shaft, they are divided into horizontal pumps and vertical pumps.

The single-stage centrifugal pump adopts a vertical pipeline structure. The inlet and outlet of the pump can be installed at any position and in any direction of the pipeline like a valve, and installation and maintenance are extremely convenient. Because the single-stage centrifugal pump adopts a single impeller structure, the working head is lower than that of the multi-stage centrifugal pump.

The multi-stage centrifugal pump has a higher working head than the single-stage centrifugal pump because the number of impellers is increased. Multistage centrifugal pumps are divided into two types: segmented multistage centrifugal pumps and split-center multistage centrifugal pumps.

Segmented multistage centrifugal pumps have good working performance, a large flow and head range, and are widely used in oil drilling. Segmented multistage centrifugal pumps are easy to manufacture, and each section of the pump body can be processed separately, but the structure is relatively complex and difficult to assemble and disassemble.

We are a professional centrifugal pump manufacturer in China. We produce a wide range of centrifugal pumps with excellent quality. If you have any needs and questions about centrifugal pumps, please feel free to contact us.

Centrifugal pumps have stable flow, smooth operation, simple maintenance, and a wide range of media applications, so they are widely used in oil drilling and industrial production.

Centrifugal pumps are divided into different types according to different internal structures and different working environments, for example. Centrifugal pumps are divided into single-stage pumps (single impeller) and multi-stage pumps (multi-impellers) according to the number of working impellers.

According to the pressure level of the pump, they are divided into low-pressure pumps, medium-pressure pumps and high-pressure pumps.

According to the impeller water inlet method, they are divided into single-side water inlet pumps and double-side water inlet pumps.

According to the direction of the pump shaft, they are divided into horizontal pumps and vertical pumps.

The single-stage centrifugal pump adopts a vertical pipeline structure. The inlet and outlet of the pump can be installed at any position and in any direction of the pipeline like a valve, and installation and maintenance are extremely convenient. Because the single-stage centrifugal pump adopts a single impeller structure, the working head is lower than that of the multi-stage centrifugal pump.

The multi-stage centrifugal pump has a higher working head than the single-stage centrifugal pump because the number of impellers is increased. Multistage centrifugal pumps are divided into two types: segmented multistage centrifugal pumps and split-center multistage centrifugal pumps.

Segmented multistage centrifugal pumps have good working performance, a large flow and head range, and are widely used in oil drilling. Segmented multistage centrifugal pumps are easy to manufacture, and each section of the pump body can be processed separately, but the structure is relatively complex and difficult to assemble and disassemble.

We are a professional centrifugal pump manufacturer in China. We produce a wide range of centrifugal pumps with excellent quality. If you have any needs and questions about centrifugal pumps, please feel free to contact us.