WhatsApp: 86-13735815206 / 86-17392256505

WeChat: 86-13735815206 / 86-17392256505

Phone: 86-29-88680837

Mail: sales@hlsolidscontrol.com

Add: Room 804, Building 1, Western Cloud Valley Phase II, Fengxi New Town, Xixian New District, Shaanxi Province

WeChat: 86-13735815206 / 86-17392256505

Phone: 86-29-88680837

Mail: sales@hlsolidscontrol.com

Add: Room 804, Building 1, Western Cloud Valley Phase II, Fengxi New Town, Xixian New District, Shaanxi Province

How to choose desander and desilter

Time: 2024-05-14 Source: Solids Control Equipment Author: Mrek

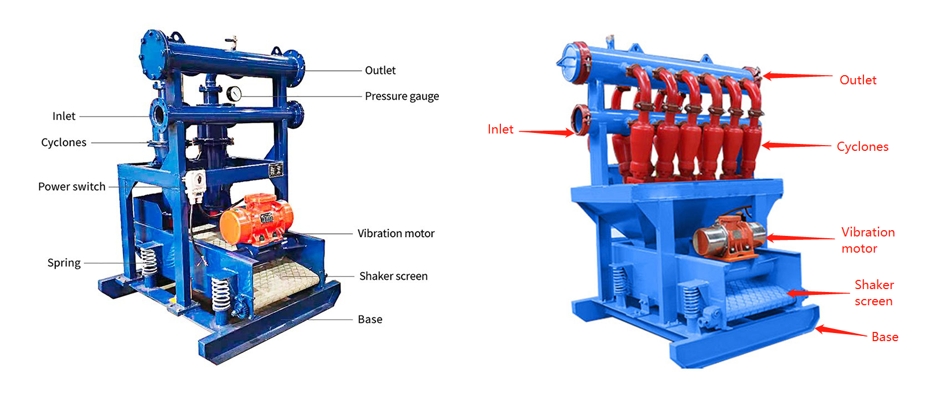

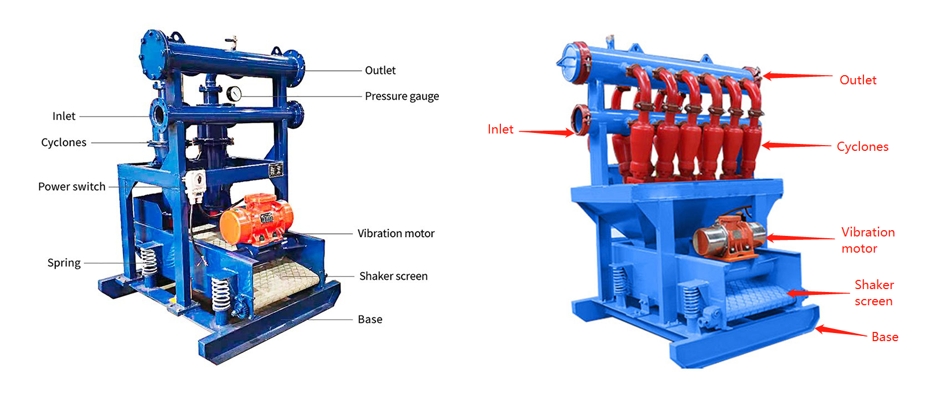

Desander and desilter are commonly used solid control equipment in oilfield drilling operations. Desanders and desilters consist of a set of hydrocyclones and a small ultra-fine mesh that processes the cyclone underflow and recovers drilling fluid. It is composed of mesh vibrating screen.

The difference is that the desander is used to remove solid particles of 30 to 74 μm, and the desander is used to remove solid particles of 10 to 30 μm. The particle size D50 in the cyclone is not only related to the structural size of the cyclone, but also to the concentration, density and inlet pressure of the drilling fluid.

Generally speaking, the separation capacity of a cyclone is related to the diameter of the cyclone. The larger the diameter, the larger the particles it can separate. On the contrary, the smaller the diameter, the smaller the separated solid particles will be.

For example, a cyclone of 152.4~304.8mm (6~12 inches) is called a "desander" and the separation point is about 40 microns. A cyclone of 50.8~152.4mm (2~6 inches) is called a "desander". ”, the separation point is about 15 microns.

The cleaner consists of a desilter and a fine-mesh vibrating screen. The screen is generally between 140 and 200 mesh (mesh 104-74 microns). The purpose is to recover part of the liquid, barite, etc. discharged through the cyclone. Cleaners are generally not recommended for use with non-weighted drilling fluids. If a cleaner is used in non-weighted drilling fluids, the shaker can be turned off and all underflow from the cyclone can be drained.

In order to meet the requirements for processing all drilling fluids, the desander and desilter must be composed of several cyclone cones. In order to ensure the normal operation of the cyclone, the inlet pressure must be maintained within the range of 0.25~0.35MPa. The desilter has many cyclone cones and long pipelines, so the liquid inlet pressure should be a larger value; the desander has fewer cyclone cones and short pipelines, so the liquid inlet pressure should be a smaller value.

The size of the inlet fluid pressure mainly depends on whether the matching of the sand pump is reasonable, so the selection of the sand pump is crucial. The lift of the sand pump is usually about 40mH2O, and the displacement can be equal to the calibrated processing capacity of the desander and desilter. , which can meet the usage requirements. At the same time, when selecting desanders and desilters, you must refer to the maximum displacement of the drilling pump in order to achieve a reasonable match.

There is no strict limit on the use time of these two types of equipment. Generally, when drilling shallow formations and soft formations, the drilling fluid contains large drilling cuttings with a high content, so both must be used at the same time; when drilling formations and hard formations, if The fine-mesh Shale Shaker can directly use the mud remover to process drilling fluid, which has little impact on the purification quality of the drilling fluid and is very economical.

The Mud Shale Shaker screen is a first-level solid control equipment. The quality of the mud shaker screen directly affects the efficiency of the entire solid control system and the service life of the desander and desilter. HL Petroleum is a professional solids control equipment manufacturer.HL Mud Shale Shaker are professional, reliable, cost-effective and customizable.welcome to consult!

The difference is that the desander is used to remove solid particles of 30 to 74 μm, and the desander is used to remove solid particles of 10 to 30 μm. The particle size D50 in the cyclone is not only related to the structural size of the cyclone, but also to the concentration, density and inlet pressure of the drilling fluid.

Generally speaking, the separation capacity of a cyclone is related to the diameter of the cyclone. The larger the diameter, the larger the particles it can separate. On the contrary, the smaller the diameter, the smaller the separated solid particles will be.

For example, a cyclone of 152.4~304.8mm (6~12 inches) is called a "desander" and the separation point is about 40 microns. A cyclone of 50.8~152.4mm (2~6 inches) is called a "desander". ”, the separation point is about 15 microns.

The cleaner consists of a desilter and a fine-mesh vibrating screen. The screen is generally between 140 and 200 mesh (mesh 104-74 microns). The purpose is to recover part of the liquid, barite, etc. discharged through the cyclone. Cleaners are generally not recommended for use with non-weighted drilling fluids. If a cleaner is used in non-weighted drilling fluids, the shaker can be turned off and all underflow from the cyclone can be drained.

In order to meet the requirements for processing all drilling fluids, the desander and desilter must be composed of several cyclone cones. In order to ensure the normal operation of the cyclone, the inlet pressure must be maintained within the range of 0.25~0.35MPa. The desilter has many cyclone cones and long pipelines, so the liquid inlet pressure should be a larger value; the desander has fewer cyclone cones and short pipelines, so the liquid inlet pressure should be a smaller value.

The size of the inlet fluid pressure mainly depends on whether the matching of the sand pump is reasonable, so the selection of the sand pump is crucial. The lift of the sand pump is usually about 40mH2O, and the displacement can be equal to the calibrated processing capacity of the desander and desilter. , which can meet the usage requirements. At the same time, when selecting desanders and desilters, you must refer to the maximum displacement of the drilling pump in order to achieve a reasonable match.

There is no strict limit on the use time of these two types of equipment. Generally, when drilling shallow formations and soft formations, the drilling fluid contains large drilling cuttings with a high content, so both must be used at the same time; when drilling formations and hard formations, if The fine-mesh Shale Shaker can directly use the mud remover to process drilling fluid, which has little impact on the purification quality of the drilling fluid and is very economical.

The Mud Shale Shaker screen is a first-level solid control equipment. The quality of the mud shaker screen directly affects the efficiency of the entire solid control system and the service life of the desander and desilter. HL Petroleum is a professional solids control equipment manufacturer.HL Mud Shale Shaker are professional, reliable, cost-effective and customizable.welcome to consult!