WhatsApp: 86-13735815206 / 86-17392256505

WeChat: 86-13735815206 / 86-17392256505

Phone: 86-29-88680837

Mail: sales@hlsolidscontrol.com

Add: Room 804, Building 1, Western Cloud Valley Phase II, Fengxi New Town, Xixian New District, Shaanxi Province

WeChat: 86-13735815206 / 86-17392256505

Phone: 86-29-88680837

Mail: sales@hlsolidscontrol.com

Add: Room 804, Building 1, Western Cloud Valley Phase II, Fengxi New Town, Xixian New District, Shaanxi Province

Enhancing drilling efficiency with a belt spray pump for drilling

Time: 2023-07-13 Source: HL Petroleum Author: hlsolidscontrol

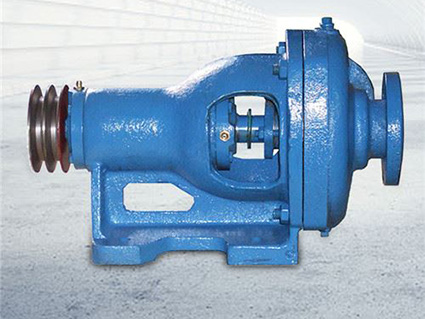

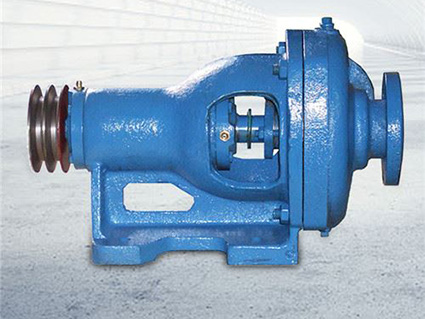

Drilling operations relentlessly pursue higher efficiency and safer practices, and in this regard, a belt spray pump for drilling plays a pivotal role. Functioning as a pumping device connected to the drilling rig or an independent power source through a robust belt drive system, a belt spray pump for drilling ensures an uninterrupted supply of fluid throughout the drilling process.

The operational mechanism of a belt spray pump for drilling is simple yet remarkably effective. Initially, it derives power from an engine directly linked to the drilling rig or an independent power unit via a sturdy belt drive system. Subsequently, the pump draws in the fluid to be sprayed through a dedicated intake port, commonly comprising water or drilling mud. The intake port is seamlessly connected to a hose or pipe, strategically submerged in a reliable water source or a specialized mud pit.

Within the pump, an impeller or a set of pistons dynamically generates the desired pumping action. As the impeller continuously rotates or the pistons diligently move back and forth, they ingeniously establish a significant pressure differential that proficiently draws the fluid from the intake port and propels it towards the highly efficient discharge port.

The fluid, propelled under substantial pressure, is efficiently expelled through the discharge port. This port, interlinked with a network of hoses or pipes, seamlessly delivers the fluid to the requisite drilling equipment, such as the drill bit, thereby facilitating the overall drilling process. The notable pressure generated by a belt spray pump for drilling effectively aids in expelling and flushing out unwanted cuttings from the borehole while simultaneously ensuring the optimal cooling of the essential drill bit.

In addition to the fundamental operational mechanism, a modern belt spray pump for drilling is often outfitted with cutting-edge control mechanisms and advanced monitoring instruments. These invaluable features allow operators to accurately adjust critical parameters like the flow rate and pressure of the fluid being sprayed. Furthermore, these monitoring instruments provide real-time data on essential variables such as flow rate, pressure, and temperature, empowering operators to make informed decisions during drilling operations.

A belt spray pump for drilling finds extensive application across various drilling operations, including water well drilling, oil and gas drilling, and geotechnical drilling. This reliable and efficient pumping device offers a continuous and consistent fluid supply, effectively optimizing drilling efficiency and ensuring the integrity and stability of the borehole throughout the drilling process.

The operational mechanism of a belt spray pump for drilling is simple yet remarkably effective. Initially, it derives power from an engine directly linked to the drilling rig or an independent power unit via a sturdy belt drive system. Subsequently, the pump draws in the fluid to be sprayed through a dedicated intake port, commonly comprising water or drilling mud. The intake port is seamlessly connected to a hose or pipe, strategically submerged in a reliable water source or a specialized mud pit.

Within the pump, an impeller or a set of pistons dynamically generates the desired pumping action. As the impeller continuously rotates or the pistons diligently move back and forth, they ingeniously establish a significant pressure differential that proficiently draws the fluid from the intake port and propels it towards the highly efficient discharge port.

The fluid, propelled under substantial pressure, is efficiently expelled through the discharge port. This port, interlinked with a network of hoses or pipes, seamlessly delivers the fluid to the requisite drilling equipment, such as the drill bit, thereby facilitating the overall drilling process. The notable pressure generated by a belt spray pump for drilling effectively aids in expelling and flushing out unwanted cuttings from the borehole while simultaneously ensuring the optimal cooling of the essential drill bit.

In addition to the fundamental operational mechanism, a modern belt spray pump for drilling is often outfitted with cutting-edge control mechanisms and advanced monitoring instruments. These invaluable features allow operators to accurately adjust critical parameters like the flow rate and pressure of the fluid being sprayed. Furthermore, these monitoring instruments provide real-time data on essential variables such as flow rate, pressure, and temperature, empowering operators to make informed decisions during drilling operations.

A belt spray pump for drilling finds extensive application across various drilling operations, including water well drilling, oil and gas drilling, and geotechnical drilling. This reliable and efficient pumping device offers a continuous and consistent fluid supply, effectively optimizing drilling efficiency and ensuring the integrity and stability of the borehole throughout the drilling process.