WeChat: 86-13735815206 / 86-17392256505

Phone: 86-29-88680837

Mail: sales@hlsolidscontrol.com

Add: Room 804, Building 1, Western Cloud Valley Phase II, Fengxi New Town, Xixian New District, Shaanxi Province

What should be paid attention to in the maintenance of the spray pump

Spray pump are mainly equipment for mud pump used in oil drilling. They are mainly used to flush and cool cylinder liners and pistons during the operation of the pump, as well as other occasions where mud is transported. Commonly used spray pumps are 32SB180J spray pump and 32PL spray pump. Pay attention to the following points in the maintenance of the spray pump:

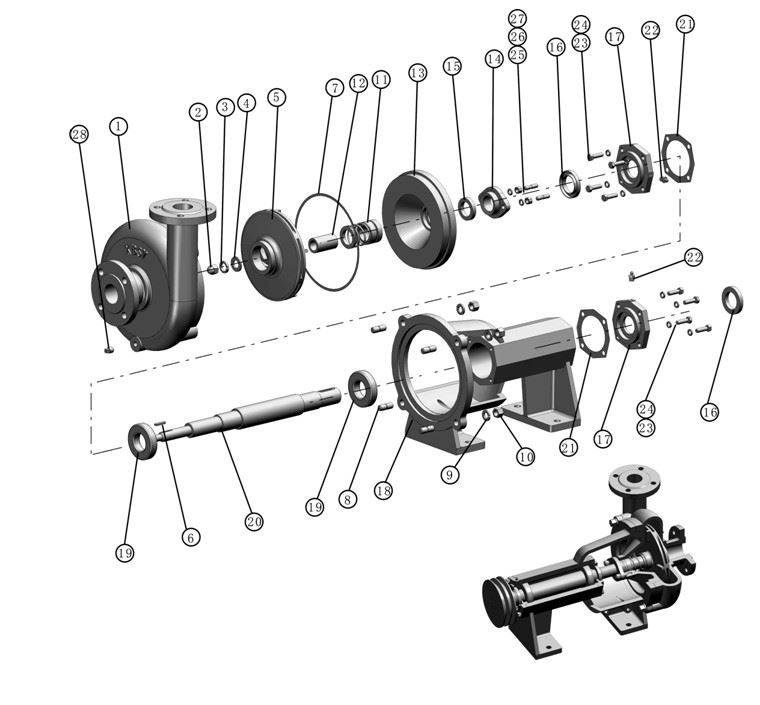

(1)Disassembly (refer to structural drawings and explosive drawing )

a.Remove pump base and body’s coupling bolt, remove pump body.

b.Disassemble impeller:first remove impeller nut, and stop washer then, remove impeller.

c.Loosen packing gland nuts, remove mechanically sealed pump cover and mechanical seal; remove the packing gland .

d.Remove two bearing glands.

e.With cuprum stick or wood block padding the shaft end, from left towards right, remove shaft and bearing components from pump base (do not damage shaft shoulder).

(2)Inspection

a.Impeller:for serious cavitations (especially main leaf ), excessive corrosion, ablation or breakage, impeller should be replace.

b.Shaft:when radial run out exceeds 0.05mm, oil seal location is seriously abraded, or shaft screw thread, groove, pedestal site or other surface is damaged, it is required to repair shaft, when the shaft cannot be repaired, replace the shaft.

c.Oil seal:disassembled oil seal must be replaced

d.Ball bearing:excessively worn bearing, excessively tight/loose bearing or that produces nose when operating must be replaced(a new bearing may be unpacked only at the time of replacement. Therefore, the bearing used for replacement must be with the same type and dimensions of the original bearing to be replaced).

(3)Assembly (refer to structural drawings and explosive drawing)

a.Before assembly, all parts, especially screw thread, bearing and bearing lubricating points, should be carefully washed. In addition, the rough parts should be polished with fine gauze.

b.Fist assemble the bearing and bearing gland at dynamic end install shaft with bearing into the pump base at left.

c.Then, mount bearing gland, breakwater ring, apply a thin layer of anti-attrition agent to shaft.

d.Assemble mechanically sealed pump cover and mechanically seal.

e.Mount impeller, pay attention to clearance between impeller back and mechanically seal pump cover, tighten lock nut.

f.Mount pump body, tighten fast bolt.

g.Assembly order is just the reverse of disassembly, after assembly, manually turn shaft, and each part shall be without any blockage.

(4)Faults and Troubleshooting

a.Mechanically real serious leakage, serious wearing and shaft surface worn.

── Remove pump body, replacing shaft if there are over deep groove by examined, otherwise replacing mechanically real.

b.Grease serious leakage at bearing glands, polyurethane seal wearing serious.

── Eliminate:replace polyurethane oil seal.

Generic thing, shall be replace polyurethane oil seal after pump operation 6 months.

c.Impeller run unnatural

── Reason:impeller installation is out of standard.

── Eliminate:adjust and installation(manually turn shaft, each part shall be without any blockage, friction).

|

Item |

Description |

Part No |

Qty. |

Item |

Description |

Part No |

Qty. |

|

1 |

Pump body |

40SB180J0001 |

1 |

15 |

Packing |

40SB180J0015 |

1 |

|

2 |

Cap nut |

40SB180J0002 |

1 |

16 |

Oil seal |

40SB180J0016 |

2 |

|

3 |

Spring gasket |

40SB180J0003 |

1 |

17 |

Bearing cover |

40SB180J0017 |

2 |

|

4 |

Washer |

40SB180J0004 |

1 |

18 |

Pump base |

40SB180J0018 |

1 |

|

5 |

Impeller |

40SB180J0005 |

1 |

19 |

Bearing |

40SB180J0019 |

2 |

|

6 |

Key |

40SB180J0006 |

1 |

20 |

Shaft |

40SB180J0020 |

1 |

|

7 |

Paper gasket |

40SB180J0007 |

1 |

21 |

Paper gasket |

40SB180J0021 |

2 |

|

8 |

Double head studs |

40SB180J0008 |

4 |

22 |

Oil cup |

40SB180J0022 |

2 |

|

9 |

Screw nuts |

40SB180J0009 |

4 |

23 |

Screw bolts |

40SB180J0023 |

8 |

|

10 |

Spring gasket |

40SB180J0010 |

4 |

24 |

Spring gasket |

40SB180J0024 |

8 |

|

11 |

Mechanical seal |

40SB180J0011 |

1 |

25 |

Double head studs |

40SB180J0025 |

2 |

|

12 |

Shaft sleeve |

40SB180J0012 |

1 |

26 |

Screw nuts |

40SB180J0026 |

2 |

|

13 |

Pump cover |

40SB180J0013 |

1 |

27 |

Spring gasket |

40SB180J0027 |

2 |

|

14 |

Packing gland set |

40SB180J0014 |

1 |

28 |

Bolt Plug |

40SB180J0028 |

1 |

Xi'an HL Petroleum Equipment Co., Ltd. specializes in the production of Mud Shale Shaker, mud cleaner, desander, degasser, centrifuge, sand pumps, spray pump, shear pumps mud mixer, mud gun, mud hoppes , drilling cutting dryer and other solid control equipment, various accessories can also be provided separately, and can be designed and customized according to customer needs, welcome to send inquiry to us sales@hlsolidscontrol.com.