WeChat: 86-13735815206 / 86-17392256505

Phone: 86-29-88680837

Mail: sales@hlsolidscontrol.com

Add: Room 804, Building 1, Western Cloud Valley Phase II, Fengxi New Town, Xixian New District, Shaanxi Province

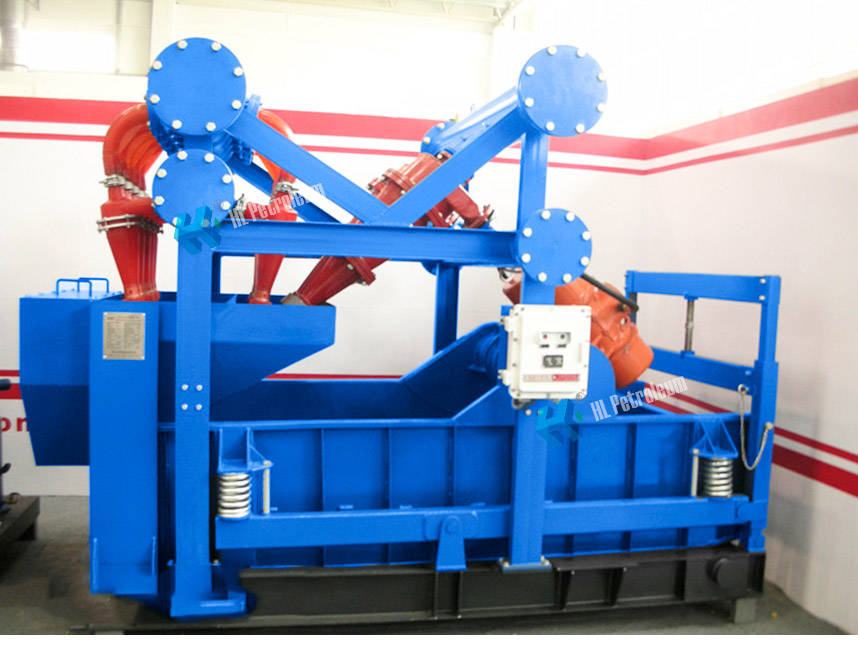

What is the drilling fluid cleaner used for?

What are the mud cleaner used for? Mud cleaners are used to remove part of the solid phase in expensive non-aggravated drilling fluids, such as potassium chloride drilling fluids. In this case, the solid phase larger than the mesh size is removed by the underflow in the desilter, while the smaller solid phase and liquid are retained in the drilling fluid system through the vibrating screen. This method will be equally effective for non-water-based drilling fluids and seawater-based drilling fluids.

In the non-weighted drilling fluid system, the underflow of the desilter can directly reach the drilling fluid tank. The centrifuge can remove the larger solid phase while retaining the smaller solid phase and most of the liquid in the drilling fluid system. This method will be very convenient if there are centrifuges available at the well site. Most of the solid phase can pass through the drilling fluid cleaner, but it is not easy to pass through the centrifuge. However, it is not worthwhile to rent a centrifuge for this purpose. The above two technologies are widely used in the field.

The high cost of the liquid phase has prompted people to find ways to recover as much of it as possible. However, the liquid phase, whether passing through a centrifuge or a drilling fluid cleaner, always contains some smaller solid phases. In some wells, these solid phases will not affect drilling speed or increase drilling costs. Generally, the impact of drill cuttings on drilling costs in aggravated drilling fluids is much greater than that of non-aggravated drilling fluids.

Usually, most of what the drilling fluid cleaner removes is barite powder. This indicates that most of the drill cuttings are dispersed in the drilling fluid. When drilling into the smectite formation with clean water, most of the solid phase dispersed in the drilling fluid is small particles. This shows that the drilling fluid has good inhibitory properties. Generally, the drilling fluid cleaner should be turned off and centrifuges are used to remove these smaller particles.

From non-weighted drilling fluids to weighted drilling fluids, most operations are very expensive and difficult. The method of recovering the liquid phase to retain the liquid phase and remove the solid phase will save costs, but it may also affect the final drilling cost, because it directly affects the complex processing costs in more cases. It is obvious that the problems caused by improper solid phase control have caused cost loss or drilling failure. The poor performance of non-weighted drilling fluids leads to increased drilling costs, which are more sensitive and difficult to detect during operation. For these reasons, the solid phase control of the weighted drilling fluid is more direct than the solid phase control of the non-weighted drilling fluid.

What is the purpose of the mud cleaner? As mentioned above, the main function of the drilling fluid cleaner is to remove solid substances in the drilling fluid whose particle size is larger than that of barite; its second purpose is to remove expensive non-aggravated materials Part of the solid phase in the drilling fluid. Xi'an HL Petroleum Equipment Co., Ltd. specializes in the production of desanders, desilters and mud cleaners. If there are customer who want to buy, please consult us.