Product details

Oil drilling explosion-proof motors use a flameproof enclosure to separate electrical parts that may produce sparks, arcs and dangerous temperatures from the surrounding explosive gas mixture. However, this kind of shell is not hermetically sealed, and the surrounding explosive gas mixture can enter the inside of the motor through the gaps between the joint surfaces of each part of the shell. When it comes into contact with ignition sources such as sparks, arcs, and dangerous high temperatures in the enclosure, an explosion may occur. At this time, the flameproof enclosure of the motor will not be damaged or deformed, but also when the explosion flame or hot gas is transmitted through the gap between the joints, Nor can it ignite the surrounding explosive gas mixture.

Oil drilling explosion-proof motor pictures

Motor Structure Description

1.) The explosion-proof structure of the motor is ExdIMb, ExdIIAT4Gb, ExdMBT4Gb. ExdIMb is suitable for the non-excavation surface environment of coal mine underground where explosive mixtures of methane or coal dust exist; ExdIIAT4Gb and ExdMBT4Gb are suitable for ||Class A or ||Class B, and the temperature is the environment where explosive mixtures of T1T2, T3 and T4 levels exist.

2.)The protection grade of the motor main body shell is IP55.

3.)The cooling method of the motor is C411.

4. )The insulation class of the motor is F, the stator winding has a large temperature rise margin and long life.

5.) The motor has a cylindrical shaft extension, which is driven by a coupling or gear.

6.) The motor stator winding adopts high-strength polyester enamelled round copper wire, which is treated by VPI vacuum pressure dipping to form a complete whole. The winding and insulation have good electrical, mechanical, moisture-proof performance and thermal stability.

7.)The rotor of the motor adopts cast aluminum structure, the rotor has been checked for dynamic balance, and the motor runs in balance, with low vibration and low noise.

8.) Motor stator and rotor punching sheets are made of high-quality electrical silicon steel sheets with high magnetic permeability and low loss, with low motor loss and high efficiency.

9.)Motor bearings are specially designed for motors with low vibration and noise. Frame size 132 and below adopt double-sided sealed bearings. Wave spring washers are installed at the shaft extension end to rely on the bearing with moderate pressure to effectively prevent the motor rotor from moving in the axial direction. Flutter. In order to use the motor for safe and reliable operation, the bearing structure of the motor frame size 160 and above is equipped with an oil injection and drainage device, and the motor frame size of 250 and above is reserved for bearing temperature monitoring sensor elements.

10.)Motor fan and windshield: This series of motors use anti-static plastic fans, which have small moment of inertia and low loss. The entire series of fans and shafts are connected by keys and operate reliably. The wind hood is a steel plate structure, which can obtain the largest ventilation area under the premise of preventing the intrusion of foreign objects of a certain size, so that the wind path is unobstructed.

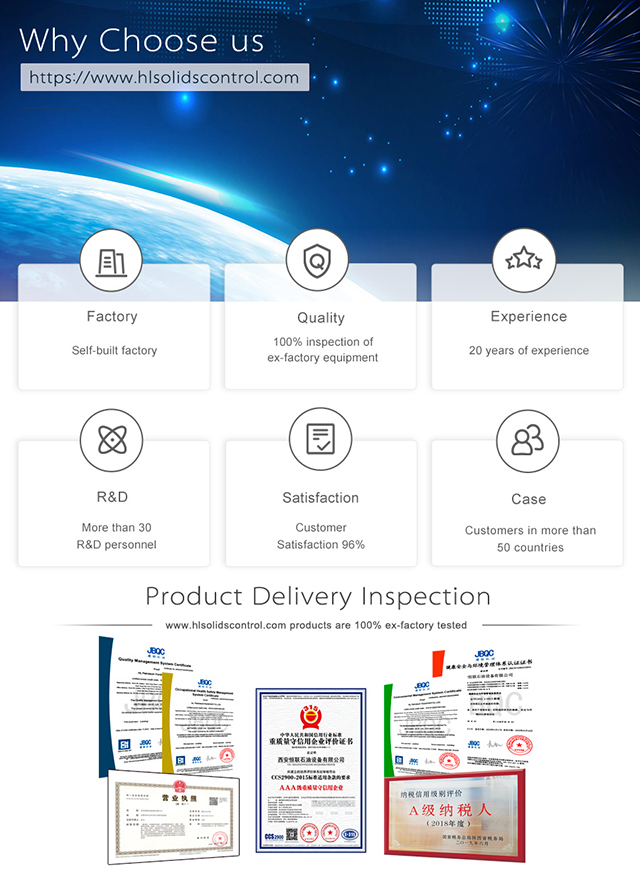

Why choose us?

HL Factory

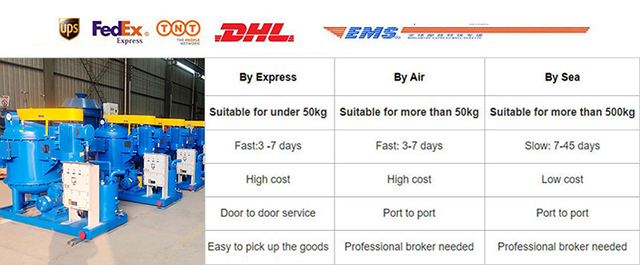

About Shipping