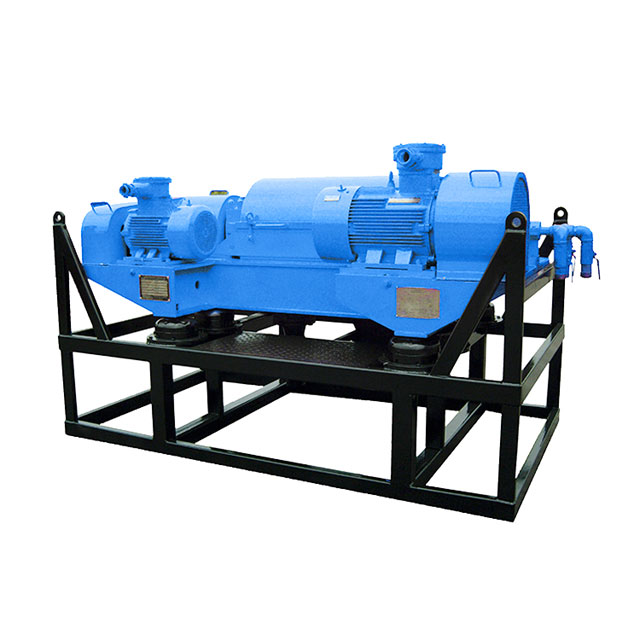

Product details

Drilling Mud Decanter Centrifuge for separation of detrital material of drilling muds is widely used in solid control system for drilling mud to separate the solids phase of mud, remove harmful fine drill solids such as debris, etc. in the mud fluid, or recover weighting materials such as barite etc. so as to reduce the cost of mud fluid.

It provides two drive modes: rated frequency drive and variable frequency drive. As to rated frequency drive centrifuge, the rotating bowl speed is fixed, so the speed can be changed only by changing drive pulley; while variable frequency drive centrifuge can achieve large-range stepless speed regulation easily with parameters displayed, e.g. speed and working current.

Drilling Mud Decanter Centrifuge Parameters

|

Parameters |

Unit |

Rated frequency LW355×1257-N |

Tri-frequency conversion LW355×1257BP-N |

Double frequency conversion LW355×1257BP-N |

||||

|

Internal diameter of bowl straight section |

mm |

355 |

||||||

|

Service length of bowl |

mm |

1257 |

||||||

|

Rotational speed of bowl (max.) |

r/min |

4000(Fresh water) |

||||||

|

Service speed of bowl |

r/min |

2800、3000 (Replacement of pulley) |

Max adjustable 3400 (1600-3200 to be recommended) |

|||||

|

G-force |

1780~1550 |

≤2296 |

||||||

|

Differential speed of conveyor |

r/min |

40 |

≤60 Adjustable |

|||||

|

Max capacity |

m3/h |

30 |

0~36(Fresh water 48) |

|||||

|

Main motor |

Model |

YB200L-4 |

||||||

|

Rated power |

kW |

30 |

||||||

|

Rated rotational speed |

r/min |

1470 |

||||||

|

Back motor |

Model |

YB160M-6 |

||||||

|

Rated power |

kW |

7.5 |

||||||

|

Rated rotational speed |

r/min |

970 |

||||||

|

Single screw feed pump |

||||||||

|

Parameters |

Model |

XG070B02ZF (with stepless speed reducer) |

XG070-0.6 (Frequency conversion for adjustable speed) |

Variable frequency |

||||

|

Rotational speed |

r/min |

196~366 |

137~408 |

|||||

|

Flow |

m3/h |

9.2~18.4 |

6.2~20.7 |

|||||

|

Pressure |

MPa |

0.6 |

0.6 |

|||||

Using Circumstance Conditions

Ambient temperature: -20°C~+50°C

Relative humidity of ambient air: ≤95%

Explosion protection mark: ExdⅡBT4

Corrosive environment: No active gas or steam that will destroy the metal

Degree of electrical protection: IP54

Drilling Mud Decanter Centrifuge Details

Drilling Mud Centrifuge Installation

A. Cranes and slings can not bear excessive load, regular check shall be given to the slings so as to ascertain whether they are in good state.

B. The sustained centers shall be checked before lifting to ensure that the strength of the sustained centers meet the requirement of hoisting.

C. Make sure the installation platform is firm enough to bear adequate weight.

Operation

A. All safety protection guards shall be installed before starting up.It is forbidden to open the guards to observe the running state of the machines.

B. During the operation of the centrifuge, touch to moving parts and rotation parts should be avoided.

C. It is forbidden to brake in any way before the equipment is stopped.

D. If there is abnormal noise and vibration, close down immediately and make troubleshooting.

E. It is forbidden to have the machine running at the rotating speed out of active speed that indicated in the instruction and nameplate.

Only after power is cut off can electrical devices be wired or plugged/unplugged!

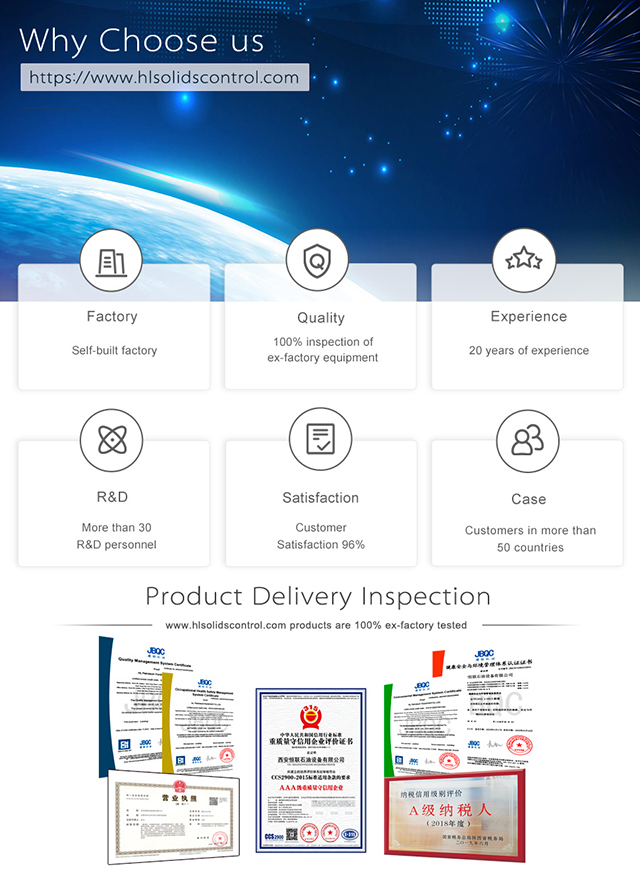

Why choose us?

HL Factory

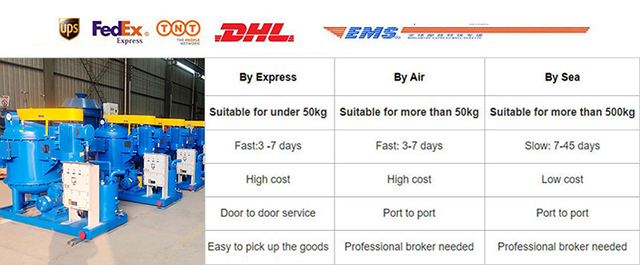

About Shipping